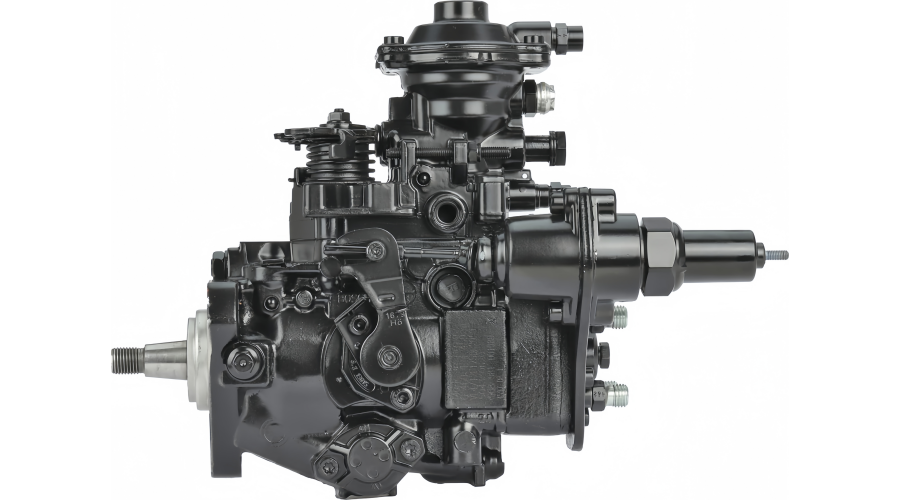

The Bosch VE (VerteilerEinspritzpumpe, meaning "Distributor Injection Pump") pump, represented by your part number, is an engineering landmark. Its design was a major step forward from its predecessors. Here are its key structural characteristics and the advantages they provided.

Core Structural Characteristics

The VE pump's brilliance lies in integrating multiple complex functions into one compact, cam-driven unit.

1. Single Plunger & Distributor Design:

Structure: Unlike inline pumps with one plunger per cylinder, the VE pump has only one high-pressure plunger. This plunger performs two motions:

Reciprocating (Up/Down): To generate high pressure.

Rotary: The plunger is housed in a distributor head and rotates, aligning its single outlet port with individual delivery ports connected to each cylinder's injector line.

Visual: Imagine a single piston pump that also spins like a rotary valve, distributing fuel in firing order.

2. Cam Plate & Roller Ring Assembly:

Structure: The plunger's reciprocating motion is driven by a cam plate (also called a swash plate or face cam) that rides on a roller ring. As the pump shaft turns, the cam plate's lobes force the plunger upward. The number of lobes equals the number of engine cylinders.

Function: This is the "heartbeat" mechanism that creates the pumping strokes.

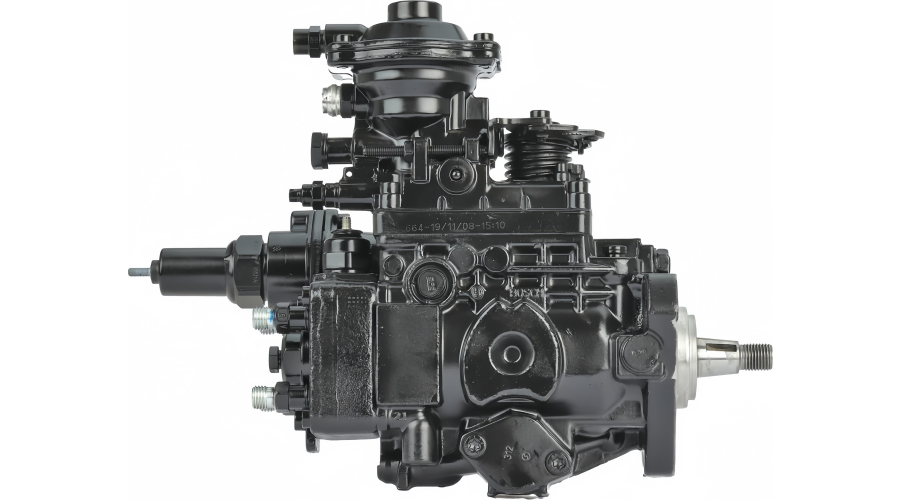

3. Integrated Mechanical Governor:

Structure: Housed within the pump body, it consists of flyweights spun by the pump shaft, connected to a sliding control sleeve via linkage.

Function: As engine speed changes, centrifugal force moves the flyweights, adjusting the control sleeve. This sleeve determines the effective stroke of the plunger, thereby controlling fuel volume to maintain a set speed (idle, max rpm) and prevent overspeed.

4. Inlet Metering & Control Sleeve:

Structure: This is a key innovation. Fuel enters the plunger chamber through inlet ports. The position of the rotating control sleeve (controlled by the governor and accelerator) determines when these ports are closed, which defines the start and end of the high-pressure delivery stroke.

Function: It meters fuel on the inlet side, at low pressure, making control smoother and less demanding on parts compared to outlet-side metering.

5. Integrated Advance Mechanism:

Structure: A hydraulic piston (advance piston) located at the front of the pump, controlled by internal fuel pressure which changes with engine speed.

Function: It rotates the roller ring relative to the drive shaft, advancing or retarding the injection timing based on engine speed. This is crucial for efficiency and emissions.

6. Optional/Common Add-Ons (Especially for TDI):

Boost Pressure Compensation (LDA): A diaphragm unit connected to the intake manifold. It increases fuel delivery as turbo boost rises, matching air with fuel for more power and preventing smoke.

Cold Start Advance (FDA): A thermo-wax or electrical device that advances timing further when the engine is cold to improve starting and reduce white smoke.

Electro-Magnetic Shut-off Valve: A solenoid valve in the fuel inlet that cuts fuel when the ignition is off, allowing the engine to stop cleanly.

Advantages (Why This Design Was Revolutionary)

The integrated structure delivered significant benefits over older inline pumps:

1. Compactness & Light Weight:

Having one plunger for all cylinders instead of 4, 5, or 6 made the pump dramatically smaller, lighter, and less expensive to manufacture. This allowed for easier installation in smaller engine bays.

2. Self-Lubrication & Simplicity:

3. Excellent High-Speed Performance:

4. Inherently Balanced Fuel Delivery:

Since all cylinders are fed by the same plunger, they inherently receive equal fuel quantities. This promoted smooth engine operation, unlike inline pumps where each plunger could wear slightly differently.

5. Integrated Timing Advance:

The built-in hydraulic advance mechanism was simple, automatic, and highly effective, optimizing combustion across the RPM range for better power and lower noise.

6. Tunability & Support for Turbocharging:

7. Reliability (When Maintained):

The Trade-Off (Disadvantage)

The Single Point of Failure: The major structural weakness is also its strength. The single plunger and distributor head is a highly-stressed, precision-matched pair. If it fails due to contaminated fuel or wear, the entire fuel delivery for the engine stops, unlike an inline pump where one failed plunger might only affect one cylinder.

Conclusion:

The structural design of the Bosch VE pump was a masterpiece of integrated mechanical engineering. It took the complex functions of injection—high-pressure generation, distribution, metering, timing, and speed regulation—and combined them into a single, compact, and efficient unit. This directly enabled the rise of the modern high-speed, passenger-car diesel engine in the 1980s and 1990s, balancing performance, efficiency, and cost in a way its predecessors could not.

Most Common Applications:

This pump is famously associated with Volkswagen Group vehicles, but was used by others. Key applications include:

Volkswagen / Audi: 1.6L, 1.7L, and particularly the early 1.9L TDI and TD engines.

Engines like: 1Z, AHU, AEY, 1Y, AAZ.

Models like: VW Golf III (Mk3), Jetta III, Passat B4, Audi 80/A4 (B5/B6 with these specific engines).

Other Brands: Certain models from Ford (European diesels), Opel, and others that used Bosch diesel systems.

Crucial Note: While strongly linked to the 1.9 TDI, not all 1.9 TDIs use this pump. Always cross-reference the number on your specific pump and your vehicle's engine code.