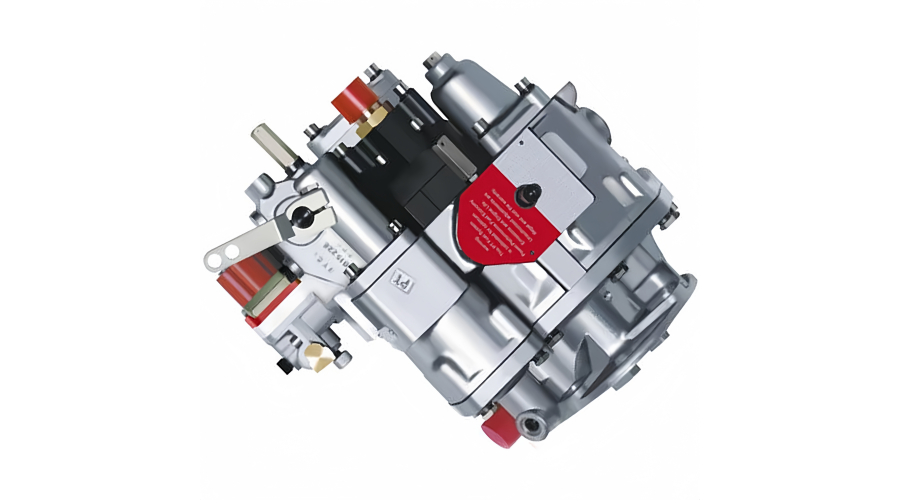

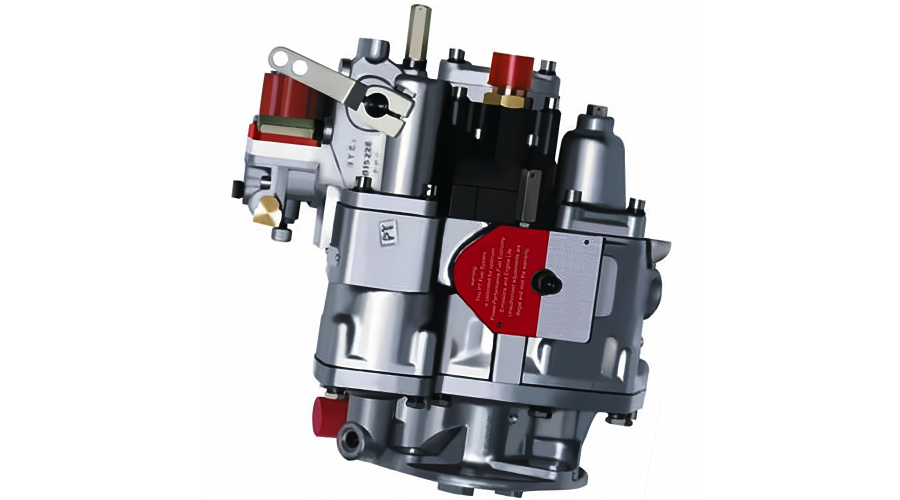

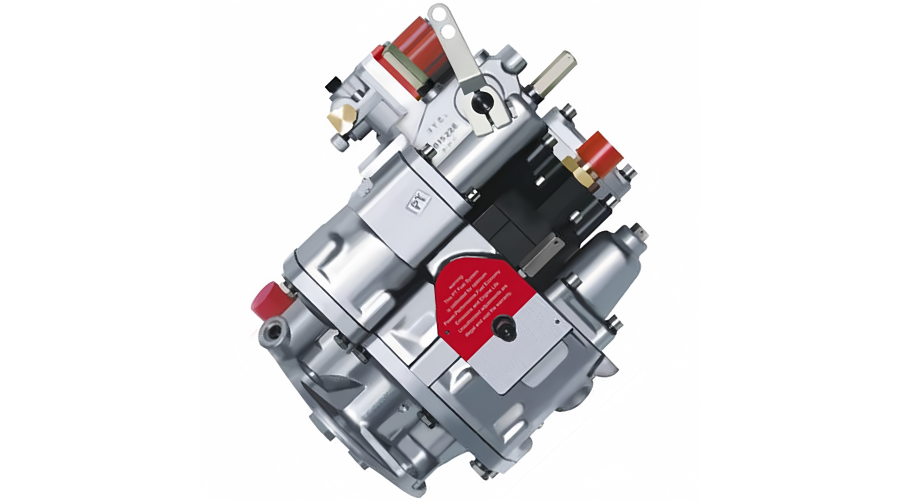

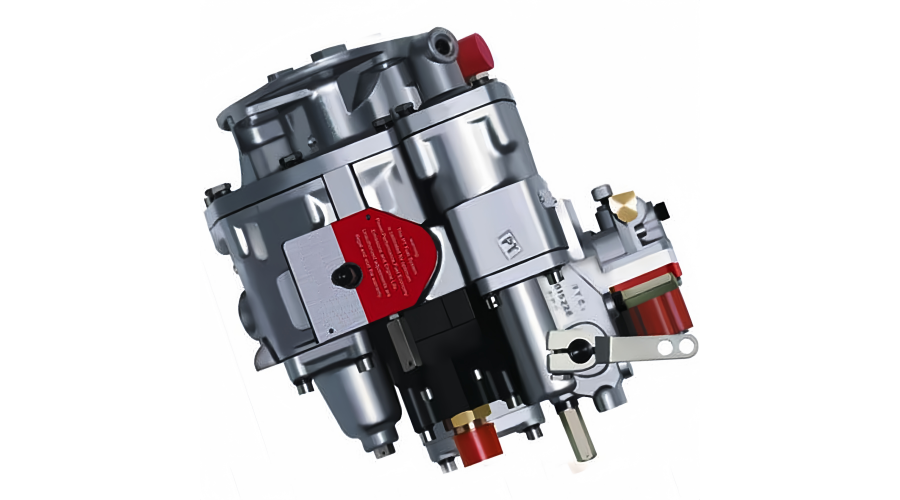

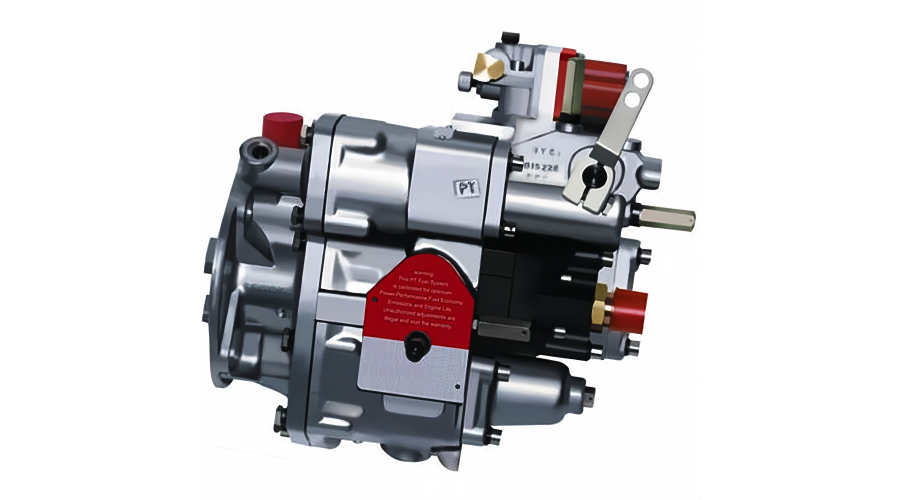

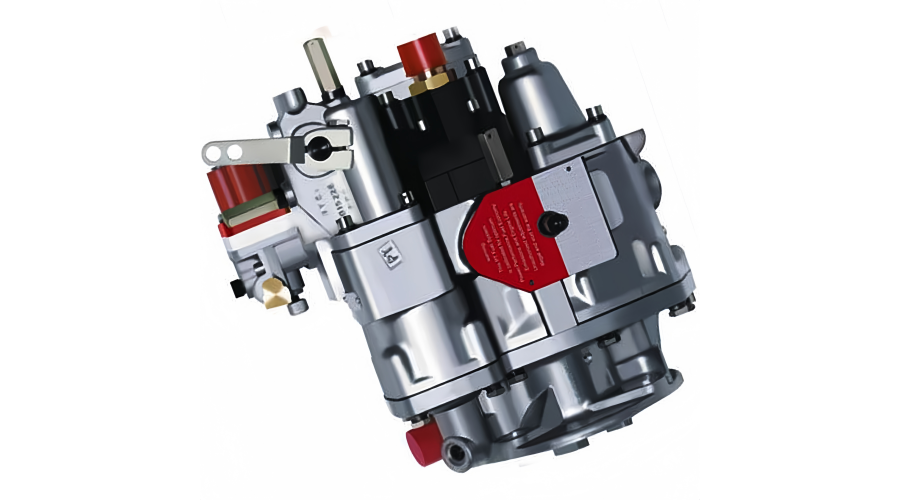

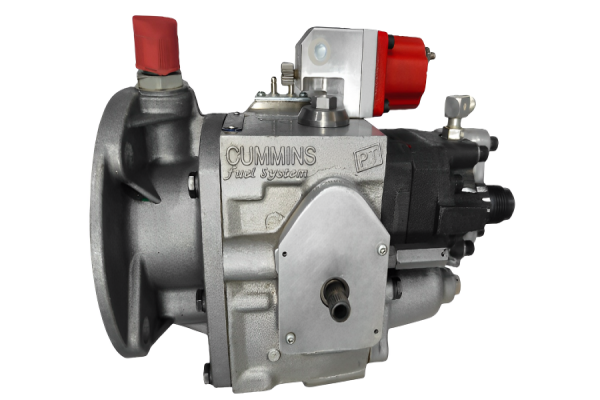

The Cummins PT (D) Pump (3034873) is a legendary piece of diesel engineering, representing a specific and highly effective philosophy of fuel injection. Here's a breakdown of its technical advantages and critical installation precautions.

Part 1: Technical Advantages of the PT Fuel Injection System & Pump

The PT system is fundamentally different from modern high-pressure common-rail (HPCR) systems or inline/rotary pumps. Its advantages lie in simplicity, reliability, and a unique operational principle.

1. Simplicity and Robustness of Design:

No High-Pressure Fuel Lines: The most significant advantage. The pump supplies fuel at a moderate pressure (up to ~250 psi) to a common rail (manifold). The high-pressure event is created inside each injector by its own camshaft-driven plunger. This eliminates the complex, failure-prone, ultra-high-pressure steel lines found on other systems.

Forgiving of Fuel Contamination: While clean fuel is always critical, the PT pump's tolerances and lower operating pressures make it slightly more tolerant of minor contamination than modern HPCR systems, which are destroyed by particles measured in microns.

2. Unique "Pressure-Time" (PT) Metering Principle:

Fuel Metering at the Injector: The pump controls the volume of fuel by regulating the pressure supplied to the injectors. The amount of fuel injected is determined by:

Fuel Rail Pressure (P): Supplied by the PT pump.

Time (T): The duration the injector's metering orifice is open, controlled by the engine's camshaft.

Self-Balancing: This system is inherently self-compensating. If engine speed drops under load, fuel rail pressure drops slightly, which reduces the fuel rate and prevents lugging and smoke.

3. Exceptional Reliability and Serviceability:

Proven Longevity: The gear-driven, mechanically governed design is incredibly durable. It's common to see these pumps last for hundreds of thousands of hours in industrial applications with proper maintenance.

Field Serviceable: Major adjustments (idle speed, high-speed governor, fuel rate) can be made on the engine with proper tools and training. Full rebuilds and calibrations require a test stand, but the design is straightforward for trained technicians.

4. Excellent Performance Characteristics:

Fast Throttle Response: The direct mechanical link from the throttle to the pump governor provides immediate response.

Stable Governor Control: The mechanical flyweight governor is very effective at maintaining a steady RPM under varying loads, crucial for generator and industrial applications.

5. Key Pump-Specific Advantages (3034873 Design):

Integrated Governor: The combination pump/governor unit simplifies the engine design and control.

Gear-Driven: Direct gear drive from the engine cam ensures positive timing and no belt/chain slippage issues.

Part 2: Critical Precautions for the Installation Process

Installing this pump is not simply "bolt on and go." Precision is paramount. The most important rule: The pump and injectors are calibrated as a matched system for a specific engine rating.

Pre-Installation Precautions:

VERIFY THE PUMP SPEC: The pump MUST be calibrated for your engine's exact model, horsepower, and application (truck, generator, marine). A pump from a 350hp N14 will not run correctly on a 525hp N14, and vice versa. The calibration code (often a tag or stamp) is critical.

Cleanliness is Non-Negotiable: Work in the cleanest environment possible. Any dirt entering the open fuel lines or pump ports can destroy injectors and the pump itself.

Have the Right Tools: You will need:

A torque wrench (in-lb and ft-lb ranges).

Dial indicator and magnetic base for timing the pump.

Feeler gauges.

New sealing gaskets and O-rings for all connections.

A priming tool or method to fill the pump with fuel before startup.

Installation Procedure Precautions:

Engine Timing Lock: Before removing the old pump, lock the engine at Top Dead Center (TDC) on cylinder #1 compression stroke using the engine's timing pins or marks. This is the single most important step to ensure correct pump indexing.

Gear Mesh Timing: The pump driveshaft has a specific gear that must mesh correctly with the engine gear train. Mark the gear orientation or follow the manual explicitly to avoid being 180° out.

Mounting & Sealing:

Do NOT use sealant on the pump mounting gasket unless specified. Use it dry and clean.

Torque the mounting bolts in a criss-cross pattern to the exact specification (e.g., 30-35 ft-lbs). Overtightening can distort the housing.

Fuel Line Connections:

The "OUT" port goes to the cylinder head fuel rail.

The "IN" port comes from the fuel filter.

The "RETURN" port goes back to the tank.

Connect these incorrectly, and the engine will not run or will be damaged.

Use new copper washers or O-rings on all banjo fittings. Torque connections carefully to avoid stripping.

Throttle Linkage & Governor Adjustment:

Connect the throttle linkage precisely as per the manual. There must be zero binding and full, free travel.

DO NOT randomly adjust the governor screws (idle speed, high-speed stop, fuel bypass). Thesewere set on a test stand. Only minor idle speed adjustment should be made after startup.

Priming and Pre-Start:

Never start the engine with a dry pump. Fill the pump housing with clean fuel through the inlet port or by using a priming pump on the fuel system.

Crank the engine with the injector lines loose at the injectors until clean, air-free fuel spurts out. Tighten the lines.

Post-Installation Precautions:

Initial Start-up: Start the engine and let it idle. Check immediately for any fuel leaks.

Timing Verification/Setting (MANDATORY):

Using a dial indicator in the timing hole on the pump, you MUST set the pump "drop" timing according to the engine's specification sheet. This is not ignition timing, but the point at which the pump's internal metering event occurs relative to the engine cycle.

Incorrect timing leads to poor power, excessive smoke, high temperatures, and engine damage.

Final Governor Check:

Once at operating temperature, check and adjust the idle speed if necessary.

Under load (dynamometer is best), verify the high-speed governor "cuts off" fuel at the correct rated RPM. An overspeeding diesel engine can explode ("runaway").