This pump is engineered for light to medium-duty, high-speed diesel engines that require a balance of performance, fuel economy, and packaging constraints. Its design scenarios include:

High-Pressure Requirement: Applications needing rail pressures of 1400 - 1800 bar for optimal atomization and clean combustion (meeting Euro IV/V/VI and EPA Tier 4 emissions standards).

Compact Installation: Where space on the engine is limited. The CP1H's radial design is more compact than an equivalent CP3 axial pump.

Cost-Sensitive Applications: While precise, the CP1H's design is often more economical to produce than its multi-cylinder predecessors, making it suitable for high-volume production engines like the ISF2.8.

Demanding Duty Cycles: It is robust enough for commercial use but is most at home in applications with relatively clean fuel systems and proper maintenance.

Typical Equipment & Vehicles

The Cummins ISF2.8 engine (using this pump) is one of the most widely deployed light-duty diesel engines globally. Equipment includes:

A. Light & Medium-Duty Trucks (Most Common Application)

Foton / Auman Trucks (China & Global Markets): The primary platform for the ISF2.8. Found in models like the Foton Ollin, Auman EST, and countless light-duty haulers.

Dongfeng Trucks

JAC (Jianghuai) Trucks

Chevrolet Silverado 2500/3500 (US Market - ~2019-2023): The 2.8L Duramax turbo-diesel option was a Cummins R2.8 (a derivative of the ISF2.8), also using a Bosch CP1H pump.

Various Global Pickup & Cargo Van Platforms.

B. Construction & Agricultural Equipment

Compact Wheel Loaders

Small Excavators

Telehandlers

Air Compressors

Irrigation Pumps

Agricultural Machinery (e.g., harvesters, tractors in lower power ranges).

C. Power Generation

Mobile & Stationary Generators (typically in the 50 kVA - 100 kVA range) powered by the QSF2.8 industrial version.

D. Special Vehicles

Light-Buses & Minibuses

Mobile Cranes

Fire Fighting Equipment

Refrigerated Trucks (Reefer units)

Critical Associated Equipment (For a Successful Repair)

When replacing the 0445020255 pump, the following associated components are highly recommended to be inspected or replaced to ensure system integrity:

Fuel Filters: ALWAYS replace both primary and secondary fuel filters. This is non-negotiable.

Fuel Lines: Inspect all low-pressure supply and return lines for cracks or leaks.

Fuel Tank: Check for sediment/water contamination. The tank may need cleaning.

Fuel Lift Pump: If the vehicle has an in-tank or inline electric lift pump, verify it is providing adequate supply pressure (specification is critical).

Common Rail & Injectors: If pump failure sent metal debris through the system, the common rail and fuel injectors are likely contaminated and may also require service or replacement. Installing a new pump on a dirty system will cause immediate failure.

High-Pressure Lines: The lines between the pump, rail, and injectors should be inspected for wear or internal degradation.

Drive Coupling: The shear coupling on the old pump must be inspected. If it sheared, all fragments must be cleaned from the gear housing.

Final Summary:

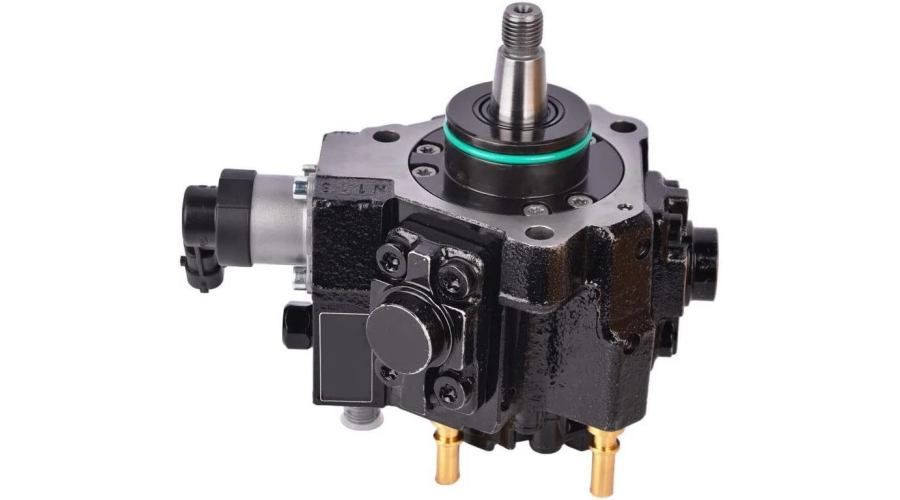

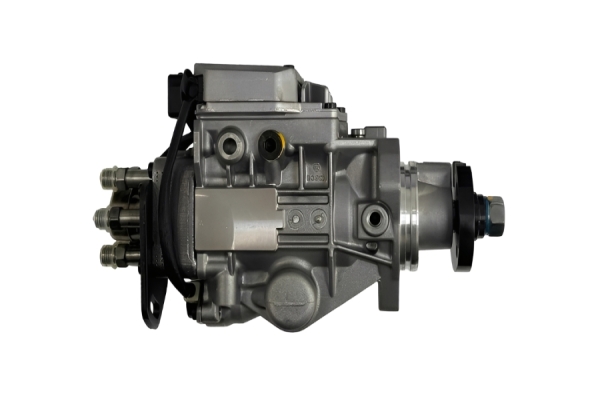

The 0445020255 is the Bosch CP1H high-pressure fuel pump for the Cummins 2.8L engine. Failure is often due to contaminated fuel. Opt for a quality remanufactured or new unit from a trusted source, factor in the core charge, and address the root cause of the failure. Professional installation is strongly advised to ensure longevity and proper operation.