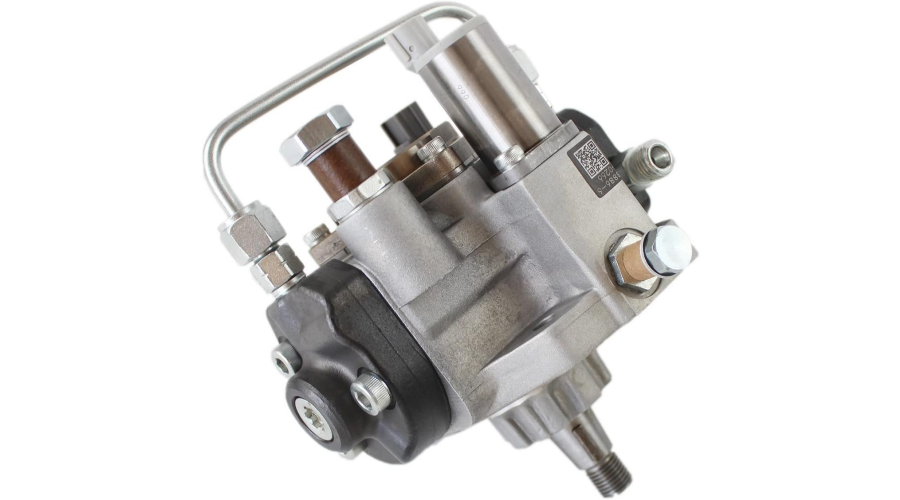

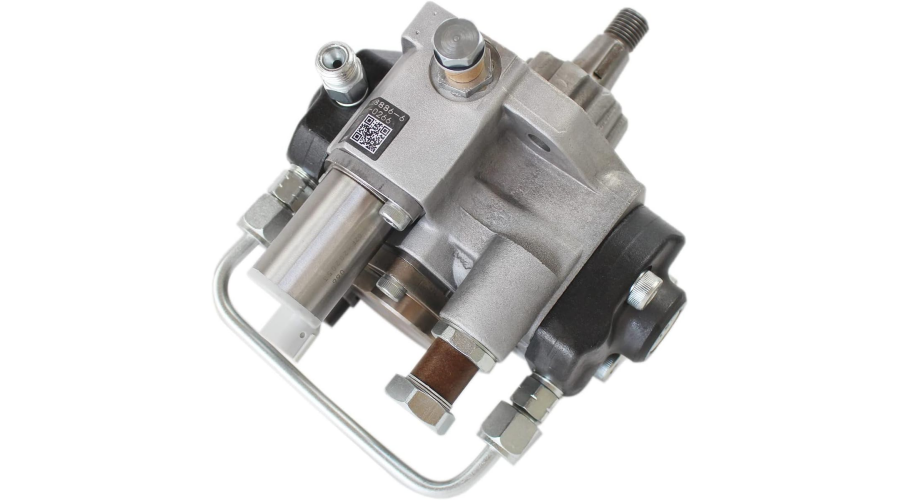

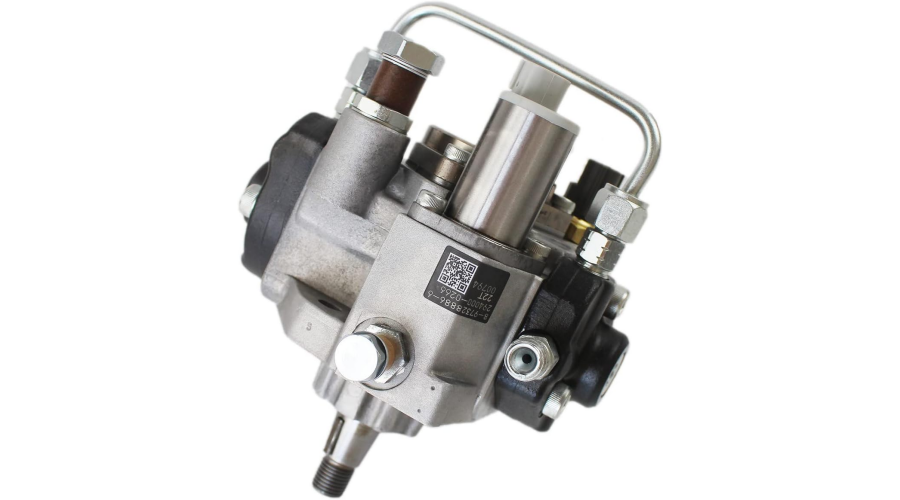

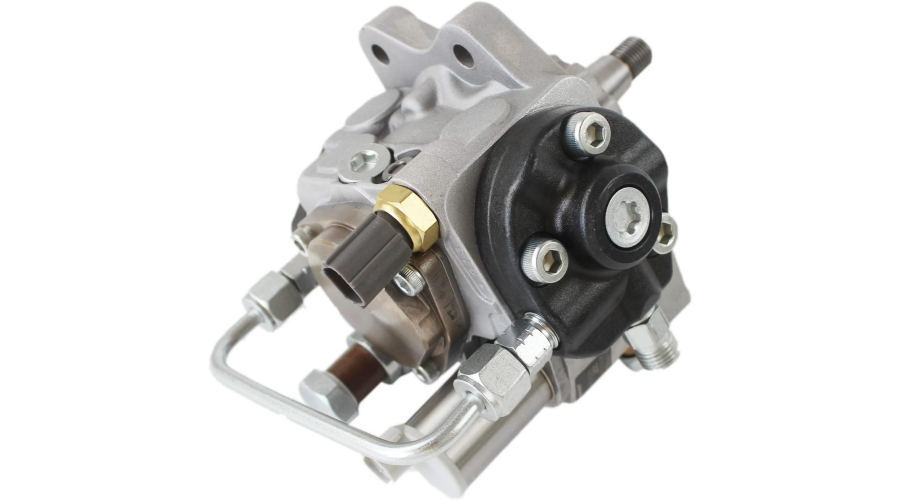

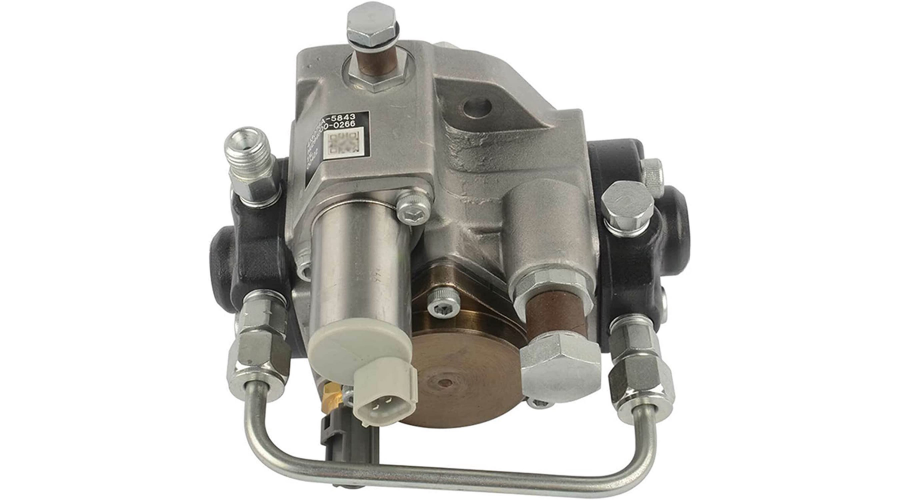

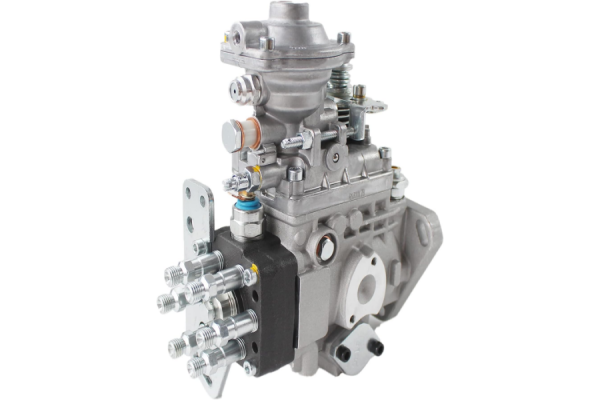

Part Number: 8-97328886-5

Part Description: Diesel Fuel Injection Pump (High-Pressure Fuel Pump) for ISUZU 4HK1 Engine

This is a critical component for the fuel system of the ISUZU 4HK1 diesel engine.

Key Details

Primary Application: ISUZU 4HK1 engine.

Engine Specs: A 5.2L, 4-cylinder, turbocharged, common-rail direct injection diesel engine renowned for its durability and power.

Vehicle Applications:

ISUZU Trucks/Buses: FSR, FTR, NPR/NQR, GIGA (light-duty versions).

Construction & Special Equipment: Used as a power unit in excavators, cranes, generators, etc.

OEM Number: 8-97328886-5 (ISUZU genuine part number).

Function & Importance

This High-Pressure Fuel Pump (HPFP) is the heart of the common-rail fuel system. It performs the vital task of taking in low-pressure fuel from the tank and pressurizing it to an extremely high level (often exceeding 1,600 bar / 23,000 psi). This high-pressure fuel is then supplied to the common rail, which distributes it to the electronically controlled injectors for precise combustion.

Its performance directly affects:

Engine power output and throttle response.

Fuel efficiency.

Emissions (smoke levels).

Cold starting capability and idle smoothness.

Common Symptoms of a Failing Pump

If this pump is failing or damaged, you may experience:

Hard Starting or Failure to Start

Significant Loss of Power & Poor Acceleration

Rough Idle or Excessive Engine Vibration

Increased Fuel Consumption

Excessive Black or White Smoke from the exhaust

Unusual Noises (loud clicking, whining, or grinding from the pump area)

The 8-97328886-5 diesel fuel pump is not a generic component; it is a state-of-the-art high-pressure common rail (HPCR) pump specifically engineered for the modern ISUZU 4HK1 engine. Its advantages and applications are deeply interconnected with the demands of contemporary diesel technology.

Here is a breakdown of its main technical advantages and the resulting application scenarios.

Main Technical Advantages:

This pump is the core of a precision, high-pressure fuel system. Its advantages stem from the common rail architecture it enables.

1. Extremely High and Stable Injection Pressure:

Advantage: Capable of generating pressures over 1,600 bar (23,000+ psi) consistently, regardless of engine speed. This is significantly higher than older in-line or rotary distributor pumps.

Technical Benefit: High pressure atomizes the diesel fuel into much finer droplets. This creates a more optimal air-fuel mixture, leading to near-complete and controlled combustion. This is the foundation for all other benefits.

2. Precise, Electronic Control (Decoupled from Engine Camshaft):

Advantage: While mechanically driven by the engine, its output is controlled by an Electronic Control Unit (ECU) via a solenoid or piezoelectric-controlled metering valve.

Technical Benefit: Injection timing and quantity are no longer mechanically limited. The ECU can command multiple, precisely timed injection events per cycle (e.g., pilot, main, post injections). This allows for optimized performance, noise reduction, and emission control.

3. Enables Superior Engine Performance & Efficiency:

Advantage: Directly contributes to higher power density and lower fuel consumption.

Technical Benefit: More complete combustion extracts more energy from the fuel (higher thermal efficiency), leading to:

Increased Power & Torque: Better engine output for a given displacement.

Reduced Fuel Consumption: Improved mileage or operating cost.

Cleaner Emissions: Lower levels of particulate matter (soot) due to complete combustion. Combined with precise post-injections, it aids in regeneration of the Diesel Particulate Filter (DPF).

4. Enhanced Durability and Reliability (When Properly Maintained):

Advantage: Designed with robust materials (high-strength steels, precision bearings) to withstand immense internal pressures and continuous operation.

Technical Benefit: Built for the long service life expected in commercial and industrial applications. Its reliability is critical for minimizing vehicle/equipment downtime.

5. Optimized for Integration with Modern Aftertreatment Systems:

Advantage: Its electronic control is essential for the vehicle's overall emission strategy.

Technical Benefit: The ECU can command the pump and injectors to operate in specific ways to support DPF regeneration and manage exhaust gas temperatures for the Selective Catalytic Reduction (SCR) system, which uses Diesel Exhaust Fluid (DEF) to reduce NOx emissions.