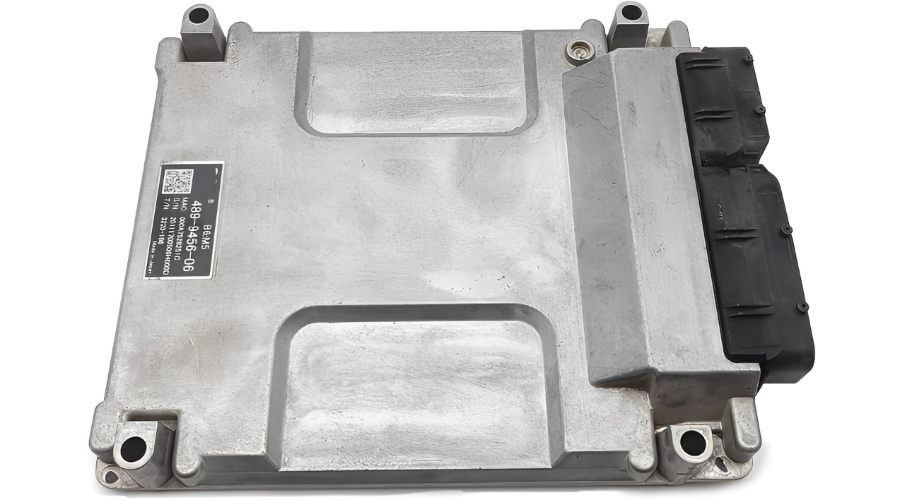

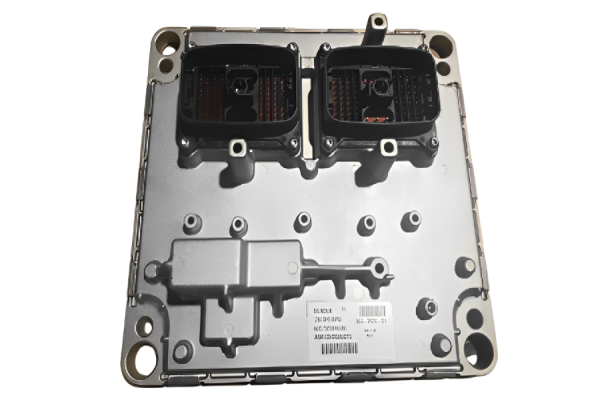

Uses a multi-pin Deutsch connector for secure connections.

Wiring harness routes signals to/from sensors, injectors, and other engine components.

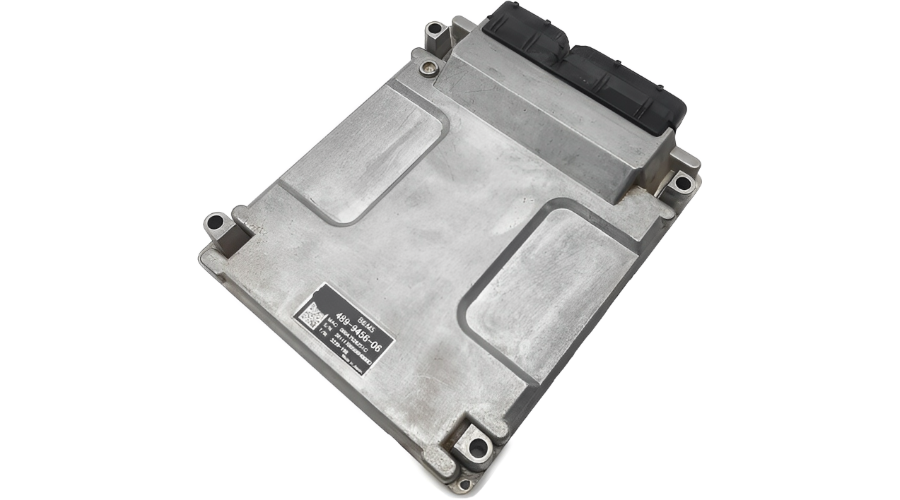

2. Key Features of the 489-9456 ECM

A. Engine Control Functions

Fuel Injection Management

Controls timing, duration, and pressure of fuel injection (for efficiency & emissions compliance).

Supports HEUI (Hydraulically Actuated Electronic Unit Injectors) in CAT engines.

Air/Fuel Ratio Optimization

Turbocharger Control (if equipped)

B. Diagnostics & Protection

Real-Time Monitoring

Fault Detection & Logging

OBD-II Compliance (for emissions-related systems).

C. Programmability & Updates

Flash-Ready – Software can be updated via CAT ET (Electronic Technician) or CAT dealer tools.

Custom Calibration – Allows tuning for specific applications (e.g., mining, marine, or heavy haul).

D. Security & Anti-Tampering

Immobilizer Function (optional) – Prevents unauthorized engine starts.

Password Protection – Limits access to critical calibration changes.

3. Applications & Compatibility

Common in CAT Engines: C7, C9, C13, and others.

Used in Equipment: Trucks, excavators, generators, and marine engines.

4. Failure Modes & Common Issues

Corrosion/Water Damage – Due to seal failure.

Electrical Shorts – From damaged wiring.

Software Corruption – Requires reprogramming.

Failed Components (e.g., capacitors, MOSFETs).