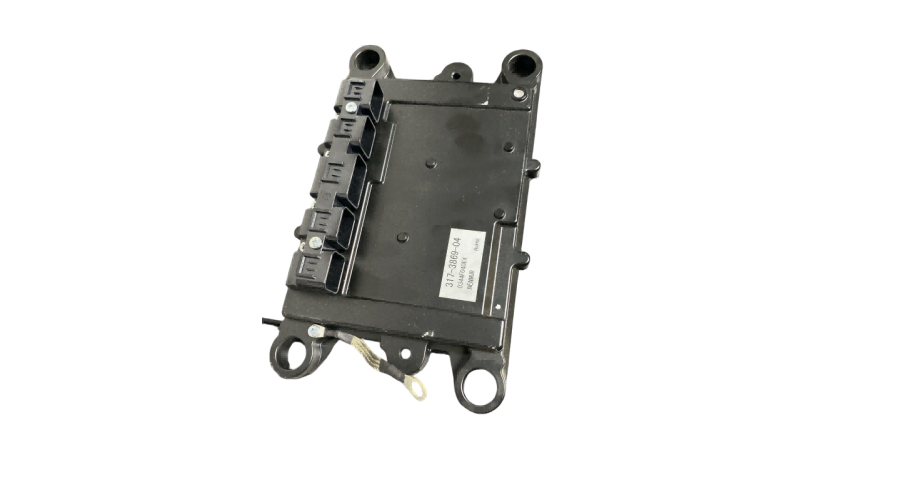

The Controller GP 317-3869 is an Electronic Control Module (ECM) designed for Caterpillar (CAT) engines and equipment. Below are its key product performance characteristics and application scenarios:

Controller GP 317-3869 Product Performance:

Engine Control & Optimization

Manages fuel injection timing, air-to-fuel ratio, and other critical engine parameters to ensure optimal performance and efficiency.

Supports real-time adjustments based on sensor inputs (e.g., temperature, pressure, speed).

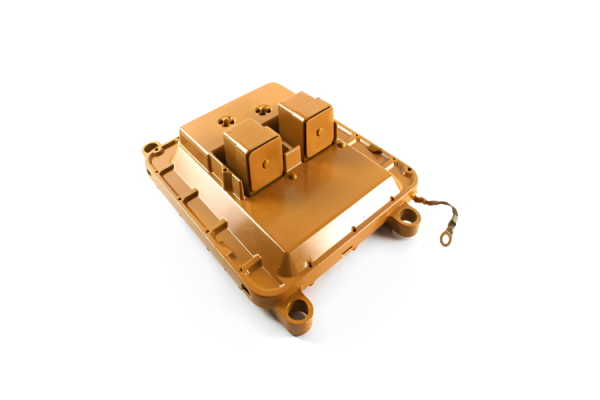

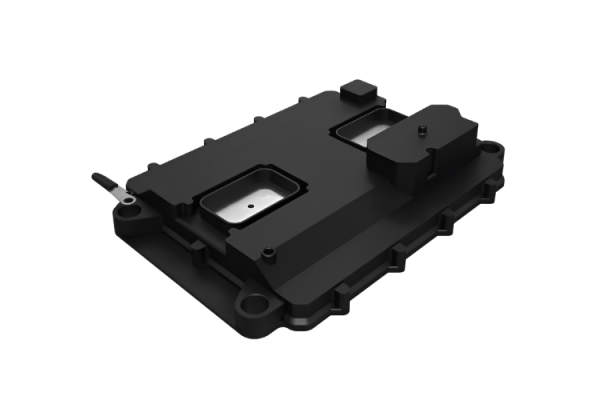

Durability & Reliability

Built to withstand harsh environments (vibration, dust, moisture, extreme temperatures).

Typically features robust housing and industrial-grade components.

Diagnostics & Troubleshooting

Provides fault code logging (via CAT ET or other diagnostic tools) for quick issue identification.

Supports onboard monitoring of engine health (oil pressure, coolant temp, etc.).

Compatibility

Designed for specific CAT engine models (verify exact compatibility with CAT’s SIS Web or dealer support).

May interface with other machine control systems (transmission, hydraulics, etc.).

Software & Calibration

Programmable for different performance profiles (e.g., emissions compliance, power tuning).

Supports flash updates to keep software current.

Application Scenarios:

Construction Equipment

Used in CAT excavators, bulldozers, loaders, and other heavy machinery to ensure precise engine control under varying loads.

Mining & Off-Highway Vehicles

Power Generation

Marine & Industrial Engines

Agriculture & Forestry

Usage and maintenance suggestions:

1. Regular diagnosis

-Using Cat ® ET or Messenger reads the fault code (such as CID 0246 CAN bus abnormality for MID 082)

and promptly cleans the sensor dirt.

2. Environmental and oil requirements

-Use clean diesel with a filtration accuracy of ≤ 5 μ m to prevent clogging of precision components;

-The working temperature should be ≤ 26 ℃ to avoid ECM component aging caused by high temperature.

3. Preventive maintenance

-Calibrate rail pressure sensors and flow meters every six months;

-Check the waterproof sealing of the wiring harness, especially in high humidity environments such as mines and ships.

4. Fault response

-Symptoms of ECM failure: sudden power drop, shaking and stalling, black smoke emission.

-Emergency plan: Immediately shut down the machine, check the power supply and grounding;