The 0414799008 is a high-pressure fuel pump for a diesel engine with a Common Rail injection system. It is not the entire injection pump, but often referred to as the "high-pressure pump" or "fuel supply pump" for the common rail.

Function: Its sole job is to take fuel from the vehicle's low-pressure fuel tank (via a lift pump) and compress it to extremely high pressures (often 1,600 - 2,500+ bar). It then continuously supplies this high-pressure fuel to the common rail (a high-pressure reservoir), which stores it and distributes it to the individual fuel injectors.

Key Concept: In a Common Rail system, pressure generation (by this pump) and fuel injection (by the injectors) are separate events, controlled by the Engine Control Unit (ECU). This allows for precise, multiple injections per cycle, leading to better power, efficiency, and lower emissions.

2. Common Applications (Vehicles/Engines)

This specific Bosch part number is found in a wide range of European diesel vehicles from the late 2000s to 2010s. Always cross-reference with your VIN number, but common applications include:

Volkswagen Group (VW, Audi, Skoda, SEAT):

2.0 TDI (CR) engines: Found in models like Golf, Passat, Tiguan, Audi A3, A4, A6, Skoda Octavia, Superb.

1.6 TDI (CR) engines.

3.0 TDI V6 engines (may use multiple pumps or a different derivative).

BMW: Various 2.0d and 3.0d models (M57, N47, N57 engine series).

Mercedes-Benz: OM640, OM651 engine series.

Ford/Peugeot/Citroën: Vehicles using the 1.6L and 2.0L Duratorq/TDV engines co-developed with PSA.

Important: The suffix of the part number (e.g., -xxx) may change for specific vehicle models. 0414799008 is often the Bosch core number, and manufacturers will have their own OE number (e.g., 03L130755, 0445010022, etc.).

3. Symptoms of a Failing Common Rail Pump (0414799008)

If this pump is failing, you will experience performance issues and potentially risk severe damage:

Hard Starting or No Start: Inability to generate sufficient rail pressure.

Loss of Power / Limp Mode: The ECU detects low rail pressure and limits engine performance to protect it.

Engine Misfires and Rough Running: Uneven fuel supply to the rail.

Increased Fuel Consumption

Loud Noise from the Pump: Whining, knocking, or rattling sounds.

Metal Contamination (CRITICAL): The most severe failure mode is internal wear of the pump's plungers or bearings. This sends fine metallic particles throughout the entire high-pressure fuel system (rail, injectors, lines). This is extremely expensive to repair, requiring replacement of the pump, rail, injectors, and lines, plus a thorough flushing.

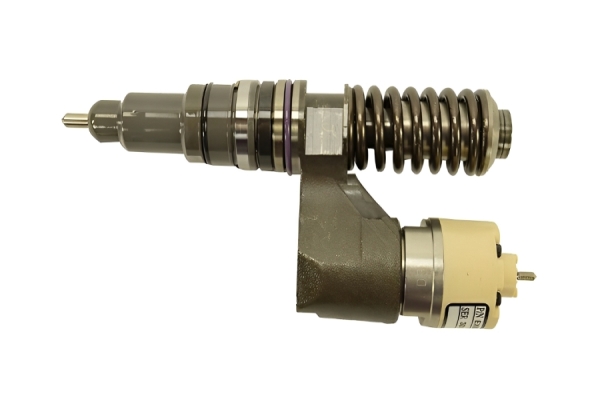

1. Structural & Design Advantages of the Bosch 0414799008 Monolithic/Unit Pump

This pump represents Bosch's CP4 high-pressure pump generation (specifically CP4.1). Its "monolithic" or "unit pump" design refers to it being a compact, integrated assembly. Key advantages include:

A. Compact & Integrated Design (The "Monolithic" Advantage)

All-in-One Housing: The pump, pressure control valve, fuel metering valve, inlet/fuel temperature sensor, and overflow valve are integrated into a single, compact aluminum housing. This reduces external high-pressure lines, potential leak points, and saves space in the increasingly crowded engine bay.

Direct Camshaft Drive: It is typically driven directly by a dedicated multi-lobe cam on the engine camshaft (or a separate jackshaft). This provides a robust, direct mechanical drive without intermediate gears or chains, improving timing accuracy and durability under high pressure loads.

B. High-Pressure Performance & Efficiency

Radial Piston Design: It uses two or three radial pistons (depending on the version) arranged around the central cam. This design allows for:

High Pressure Generation: Capable of producing the extreme pressures (up to 2,500+ bar) required for modern Euro 5/6 emission standards.

Smooth & Continuous Flow: The multi-piston design ensures a more constant flow of fuel to the rail with less pulsation compared to single-piston designs, contributing to quieter operation and stable rail pressure.

Lubrication by Fuel: The pump's internal moving parts (pistons, cam follower) are lubricated solely by the diesel fuel itself. This eliminates the need for engine oil connections, simplifies installation, but makes clean fuel absolutely critical.

C. Precise Electronic Control

Integrated Fuel Metering Unit (FMV): This is a key advantage. An electrically controlled solenoid valve (the FMV) on the pump's low-pressure inlet side precisely regulates how much fuel enters the high-pressure chambers. The Engine Control Unit (ECU) varies this based on demand, minimizing excess fuel heating and improving overall system efficiency.

Integrated Pressure Control Valve (PCV - on some versions): Some variants have a valve on the high-pressure side for fine-tuning rail pressure, working in tandem with the rail pressure sensor.

D. Material & Manufacturing Precision

Hardened Steel Components: The radial pistons, cam plate, and bore are manufactured from specially hardened steels to withstand immense cyclic stresses.

Extreme Precision Tolerances: The sealing surfaces and piston/cylinder clearances are machined to micron-level tolerances. This is why it is so sensitive to contamination—even particles smaller than a human hair can cause catastrophic abrasive wear.

2. Installation Precautions for Replacing the Bosch 0414799008 Pump

WARNING: Improper installation is the leading cause of premature pump failure. Follow these steps meticulously.

Phase 1: Pre-Installation Preparation (THE MOST CRITICAL STEP)

Confirm the Failure Root Cause: Use diagnostics to verify the pump is faulty. Check live data for low rail pressure. Rule out issues with the low-pressure supply system (in-tank lift pump, pre-filter) first. A starving pump will fail quickly.

Assess for Metal Contamination:

Inspect the Old Pump's Inlet: Remove the fuel line from the pump inlet. Swab with a white cloth or magnetic pick-up tool. Any shiny metallic particles indicate catastrophic internal wear.

If Metal is Found: You must perform a complete system flush. This is non-negotiable. The plan must include replacing or professionally cleaning the:

Gather Correct Parts & Tools:

New Pump Kit: Ensure it's the exact correct part number. Kits often include new seals and bolts.

NEW High-Pressure Fuel Filter: This is mandatory.

NEW Fuel Line Sealing Washers/O-rings: For all connections (low-pressure inlet, return line, high-pressure outlets). Never reuse old seals.

Torque Wrench (in Nm and capable of low torque settings).

Diagnostic Scan Tool capable of performing adaptations and bleeding procedures for your specific vehicle (e.g., VCDS, Delphi, Autel, OEM tool).

Cleanliness Supplies: Lint-free rags, plastic caps/plugs to cover open ports.

Phase 2: Removal & Installation Procedure

Depressurize the System:

Disconnect the fuel pump fuse/relay.

Start the engine and let it stall. Crank for an additional 3-5 seconds.

Wait at least 30 minutes for any residual pressure to dissipate.

Ultra-Clean Workspace:

Clean all dirt/debris from around the pump and fuel connections before disassembly.

The moment a fuel line is disconnected, immediately cap both the line and the pump port with clean plastic caps or lint-free plugs to prevent ingress of dust.

Careful Removal:

Label all electrical connectors and hoses.

Drain fuel from the pump if possible.

Note the exact orientation of the pump drive coupling to the camshaft lobe before removal.

Remove mounting bolts in a criss-cross pattern. Lift the pump straight out.

Prime the New Pump:

DO NOT INSTALL DRY. Before mounting, fill the pump's fuel inlet port with clean, fresh diesel fuel or the manufacturer's specified priming fluid. Manually rotate the drive lug (if possible) to help distribute fuel internally. This prevents dry-start scuffing.

Installation:

Lubricate new seal rings with clean diesel fuel only (no grease or oil).

Carefully align the pump's drive lug with the camshaft drive. Do not force it.

Hand-tighten all new mounting bolts.

Torque to Specification: Follow the manufacturer's exact torque sequence and value (typically a multi-step, angle-torque procedure, e.g., 5 Nm + 90°). This is crucial for sealing and preventing housing distortion.

Connect all fuel lines with new seals, torquing to spec (often low torque, e.g., 25-30 Nm for high-pressure lines).

Phase 3: Post-Installation & Commissioning

Prime the Low-Pressure System:

Bleed the System: Follow the vehicle-specific procedure using your scan tool. This typically involves activating the low-pressure pump and the pump's Fuel Metering Valve (FMV) to purge air.

Start and Check for Leaks:

Perform ECU Adaptation (CRITICAL):

Using your diagnostic tool, access the engine control unit.

Perform the "Fuel Pump Basic Setting" or "Rail Pressure Adaptation" procedure. This calibrates the ECU to the new pump's flow characteristics. Skipping this step can cause poor performance, DTCs, and premature failure.

Test Drive & Final Check:

Clear all fault codes.

Perform a test drive, monitoring live data for stable specified vs. actual rail pressure across the RPM range.

Where to buy:

Rsolid is a professional manufacturer of diesel engine system components, providing high-quality and durable engine parts for different brands of engines, or producing fuel injectors and diesel pumps according to your requirements. The company is positioned as a professional and excellent supplier of automotive parts for foreign trade, including high-quality fuel injectors and diesel pumps. With years of international market experience, Rsolid has become a reliable partner for global customers seeking authentic Bosch products and comprehensive value-added services. The company is firmly committed to quality assurance, typically supported by international certifications commonly found in the automotive parts industry, ensuring that all parts undergo rigorous flow, pressure resistance, and leak integrity testing before being sold. Rsolid's business model typically includes maintaining a diverse and comprehensive inventory of OEM and high-end aftermarket parts, and offering cross compatible options to meet a wide range of applications and global customers from individual workshops to large fleet operators. If you are looking for diesel injectors or OEM engine diesel pumps, please feel free to contact us at any time .