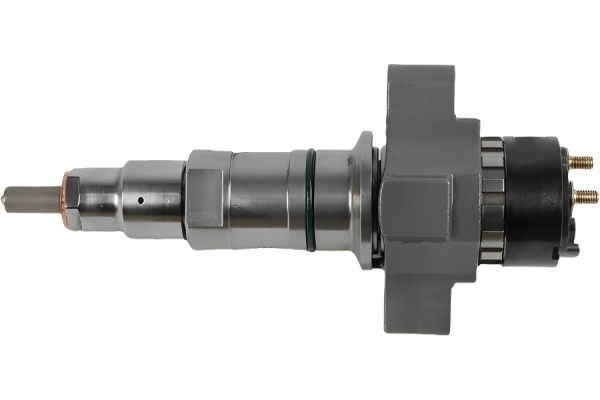

The part number 28457195 is a Common Rail (CR) fuel injector that is marketed as compatible with the Doosan D34 engine.

Core Information: The Doosan D34 Engine

The Doosan D34 is a 3.4-liter, 4-cylinder turbocharged diesel engine widely used in:

Doosan/Daewoo excavators (e.g., Solar 130/140/150/V, DX140/DX140LC)

Doosan wheel loaders and other construction equipment.

Various industrial generators and agricultural machinery.

It's a modern, efficient engine that relies on a high-pressure common rail fuel system for performance and emissions control.

Let's take a look at the features of this 28457195 common rail injector:

1. Core Structural Advantages

The design of a solenoid or piezo-actuated common rail injector is a marvel of precision engineering.

Monoblock Construction: The injector body is typically a single, hardened steel forging or machining. This provides immense strength to withstand constant internal pressures exceeding 2,000 bar (29,000 psi) and peak pressures even higher, preventing fatigue and cracking.

Multi-Stage Valve Design: Utilizes a sophisticated hydraulic servo system. A small solenoid or piezo actuator controls a small pilot valve, which uses fuel pressure itself to amplify the force and open/close the much larger main needle valve. This allows for incredibly fast and powerful actuation with relatively low electrical energy.

Ultra-Precision Machined Components:

Nozzle & Needle: The tip features micro-machined spray holes (often laser-drilled) and a lapped needle that fits with micron-level clearance. This ensures a perfect seal and precise fuel atomization.

Control Pistons & Bore: The hydraulic amplifier components are matched to tolerances of a few microns for consistent response.

Integrated Components: Houses critical elements—the solenoid coil, electrical connector, pressure chambers, and the nozzle—in one compact, sealed unit. This simplifies installation and improves reliability.

2. Key Technological Advantages (The "Common Rail" Edge)

These are the features that enable the Doosan D34's efficiency, power, and clean emissions.

Decoupled Pressure Generation and Injection: Unlike older systems, fuel pressure is generated by a separate high-pressure pump and stored in a common "rail" (manifold). This means injection pressure is available on-demand and is independent of engine speed. The injector can deliver fuel at optimal pressure even at low RPM.

Multiple Injection Events per Cycle: This is the most significant technological leap. The injector's speed and ECU control allow for:

Pilot Injection: A tiny, pre-injection of fuel before the main event. This gently increases cylinder pressure and temperature, dramatically reducing combustion noise ("diesel knock") and NOx formation.

Main Injection: The primary power-delivery charge, precisely shaped by the ECU.

Post Injection: A small injection after the main event to boost exhaust temperature for the Diesel Particulate Filter (DPF) regeneration.

Late Post Injection: For active DPF regeneration, injecting fuel that passes to the exhaust to create a burn-off of soot.

Extreme Speed and Precision: A modern solenoid injector can complete a full open-close cycle in under 1 millisecond. Piezo injectors (used in later, more advanced engines) are up to 4x faster. This allows for injection timing and quantity to be controlled with crank-angle-degree accuracy.

Adaptive Fuel Delivery: The ECU can adjust the injection parameters in real-time based on load, temperature, altitude, and fuel quality, ensuring optimal performance and protection.

3. Advantages Specific to the Engine (Doosan D34 Performance)

Improved Power & Torque: High, constant pressure and precise injection lead to better fuel atomization (tiny droplets), resulting in more complete and efficient combustion.

Enhanced Fuel Efficiency: Multiple injections and optimal timing extract more energy from each drop of fuel.

Reduced Emissions: Enables the engine to meet Tier 3/4, Stage IIIA/IV emissions standards. Pilot injection cuts NOx, high pressure reduces soot (particulates), and post-injection manages the DPF.

Smoother & Quieter Operation: The elimination of diesel knock via pilot injection leads to a much more refined engine sound and feel.

Cold Start Performance: High pressure ensures good atomization even when the engine is cold, improving startability.

What to Look for in a Quality Aftermarket Injector (like 28457195):

A superior aftermarket part doesn't just copy the structure; it leverages technology in its manufacturing and validation.

Advanced Nozzle Technology: Use of sac-less or VCO (Valve Covered Orifice) nozzle designs to reduce fuel dribble and hydrocarbon emissions.

Enhanced Materials: Use of higher-grade steels, more wear-resistant coatings on the needle, and improved seal materials for longer life, especially with today's low-lubricity Ultra-Low Sulfur Diesel (ULSD) and biodiesel blends.

Precision Manufacturing: Utilization of laser welding and automated, clean-room assembly to ensure contamination-free, consistent products.

Rigorous Testing & Balancing: Each injector should be dynamically flow-tested on a bench. The ECU's coding system relies on each injector having a precise flow characteristic. A quality manufacturer will test and provide an accurate QA Code to ensure all injectors on an engine are flow-matched.

Improved Solenoid Design: Lower electrical resistance coils for faster response and reduced ECU load.