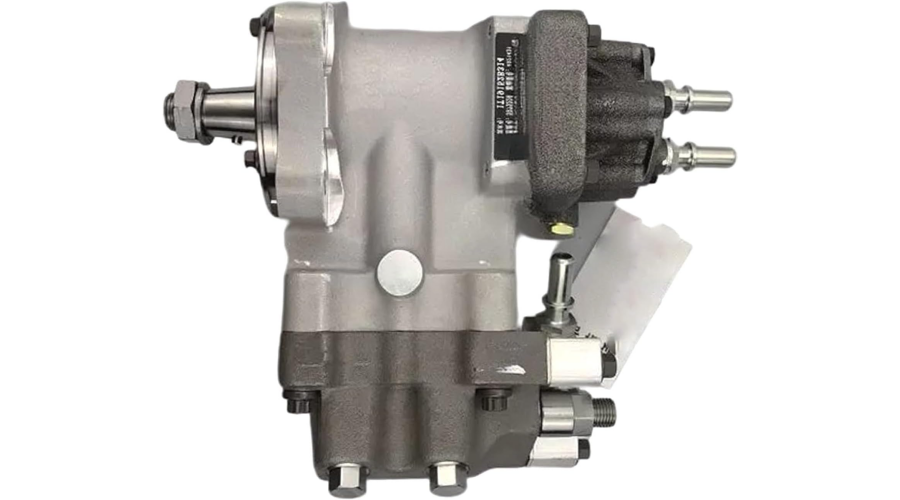

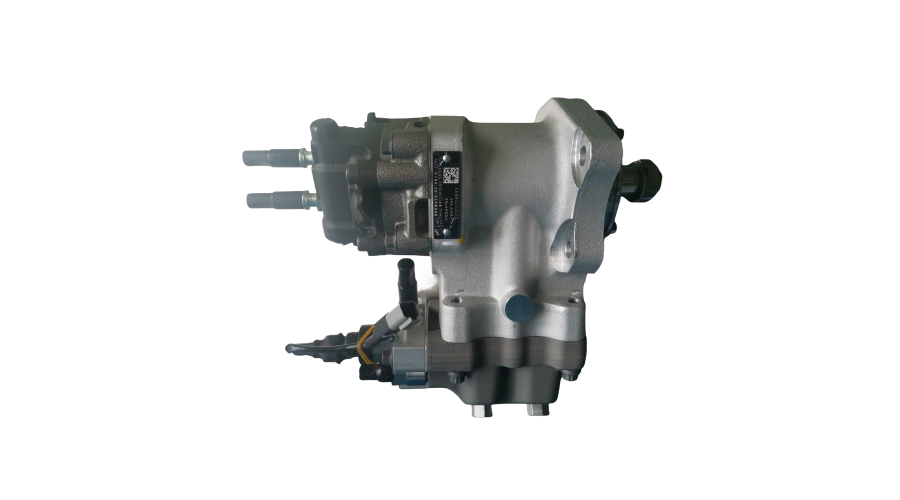

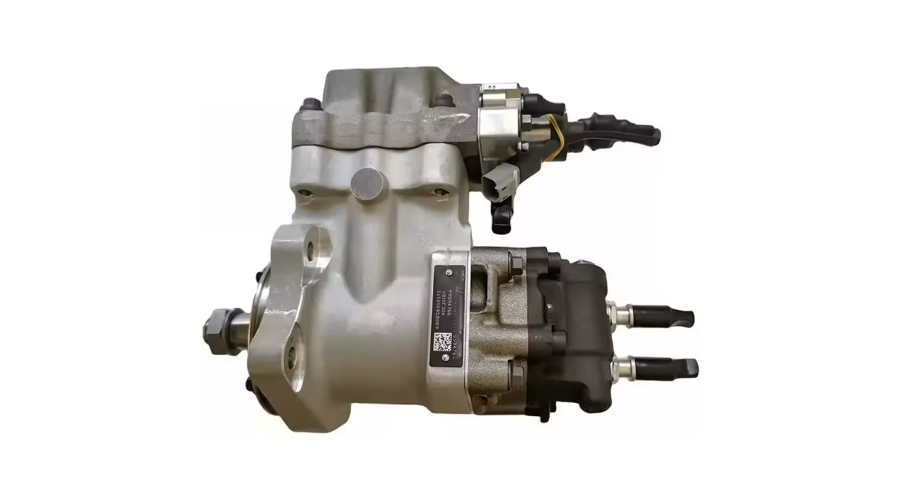

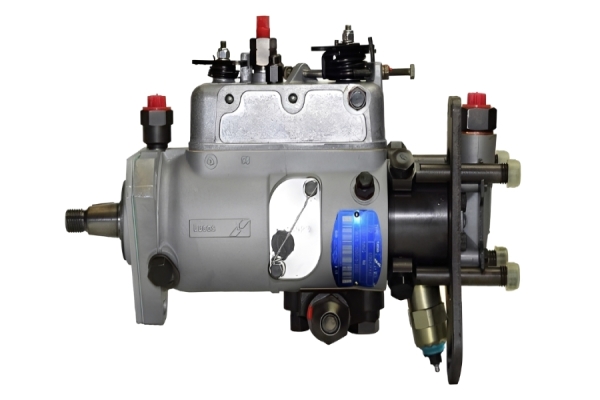

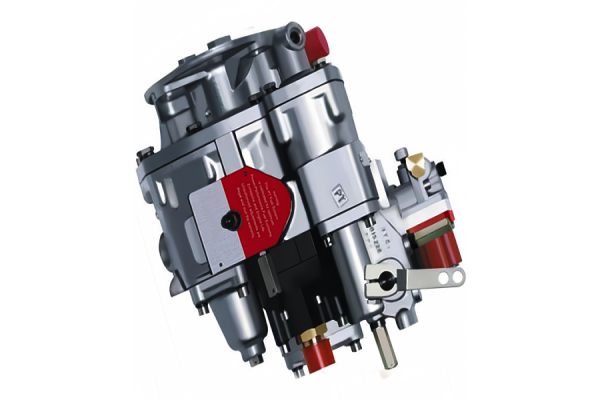

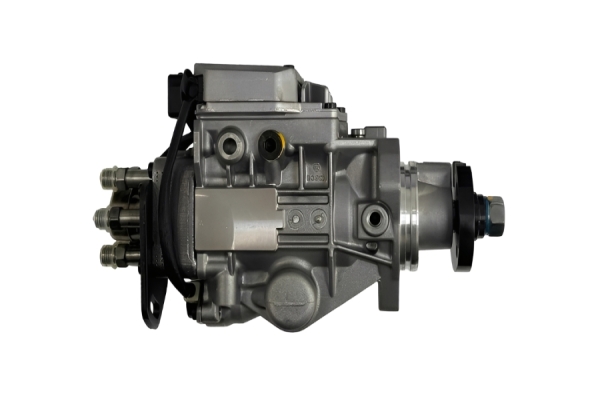

Core Information: Part #5594766

This is the Cummins OEM part number for a high-pressure fuel injection pump, more specifically a Bosch VP44 rotary distributor-type pump.

It is a direct injection pump that delivers precisely timed, high-pressure fuel to the injectors.

Primary Application: Compatible Engines

This pump is most famously used on the following Cummins 8.3L (8300 cc) engines:

Cummins ISC 8.3L (Very common in medium-duty trucks and school buses)

Cummins ISL 8.9L (Note: The ISL is actually 8.9L, but this pump is used on many earlier ISL models. It's crucial to verify your exact engine serial number).

Earlier Mechanical C Series 8.3L engines (before full electronic control).

Important: While it's predominantly an 8.3L pump, it was also used on some 5.9L and other configurations. ALWAYS verify your engine's full model and serial number (ESN) against the pump's application list before purchasing. The ESN is the ultimate authority for correct parts matching.

Key Features & Specifications

Type: Bosch VP44 electronically controlled rotary distributor pump.

Control: Electronically controlled by the engine's Electronic Control Module (ECM). It has a built-in "head plunger" for pressure generation and an electronic control unit (ECU) on the side of the pump itself.

Function: It generates the high pressure needed for injection (upwards of 20,000 psi), times the injection event, and meters the fuel. The engine's main ECM sends commands to the pump's internal ECU.

Common Rail? No. The VP44 system is an injection-pump-based system, not a common rail system. High pressure is generated in the pump and sent directly to the injectors via lines.

Common Symptoms of a Failing 5594766 Pump

If you're looking for this part, your pump might be showing signs of failure:

Hard Starting or No Start: Lack of sufficient fuel pressure.

Loss of Power / Poor Performance: Pump cannot deliver required fuel volume or pressure.

Engine Stalling: Intermittent failure of the pump's internal electronics or fuel supply.

Rough Idle or Misfiring: Uneven fuel distribution to cylinders.

Increased Fuel Consumption.

"No Comm" or Pump-Related Fault Codes on diagnostic scanner (e.g., Cummins Insite).

Crucial Note: Many VP44 pump failures are caused by low fuel pressure from the lift pump (the low-pressure transfer pump). The VP44 relies on adequate supply pressure (typically 10-15 psi) for lubrication and cooling. Always check lift pump pressure before condemning the high-pressure pump.

The Cummins 5594766 (Bosch VP44) pump represented a significant technological leap when it was introduced, bridging the gap between purely mechanical injection and full common rail systems. Its structural advantages were key to its widespread adoption in medium-duty diesel engines like the Cummins 8.3L.

1. Compact, Integrated Design (All-in-One Unit)

Advantage: The VP44 integrates the high-pressure pumping mechanism, fuel metering, timing control, and its own electronic control unit (ECU) into a single, relatively compact housing.

Benefit: This saves space on the engine, simplifies external wiring (compared to systems with separate, remote ECUs), and reduces the number of external connections and potential leak points. The "pump-mounted ECU" was a key innovation.

2. Rotary Distributor Design (vs. Inline Pump)

3. Direct High-Pressure Generation

Advantage: The pump generates injection pressure internally (up to 23,000 psi / ~1,600 bar in later versions) and sends it directly to the injectors via high-pressure lines.

Benefit: This was a major step up from its predecessor, the VE pump, allowing for higher injection pressures which led to:

4. Advanced Electronic Control (The Key Advantage)

This is the pump's most significant structural advantage over purely mechanical pumps.

Integrated ECU: The onboard ECU communicates with the engine's main ECM via a high-speed datalink. It receives commands for fuel quantity and injection timing.

High-Speed Solenoid Valve: The heart of its control is a spill solenoid valve. This valve, controlled by the ECU with extreme precision (in microseconds), can cut off the pumping chamber at any point in the plunger's stroke.

Benefit - Full Authority Electronic Control:

Dynamic Timing: Injection timing could be optimized in real-time for RPM, load, and temperature, improving efficiency and cold starts.

Precision Metering: Extremely accurate fuel control for each injection event.

Pilot Injection Capability (on some versions): The solenoid's speed allowed for a small "pilot" injection before the main injection event, drastically reducing combustion noise (the characteristic diesel "knock").

5. Simplified Drive Mechanism

Advantage: It is typically driven directly from the engine's gear train or timing belt, often at half engine speed (camshaft speed).

Benefit: This reduces the rotational speed and mechanical stress on the pump's internal components compared to pumps running at full crankshaft speed, contributing to potential durability.

6. Self-Lubrication and Cooling

Advantage: The pump is lubricated and cooled by the fuel itself. The internal components are bathed in a continuous flow of diesel fuel supplied by the lift pump.

Benefit: Eliminates the need for a separate engine oil circuit to the pump, simplifying integration. However, this also creates its primary vulnerability .