The Bosch 2445110060 is indeed the CP3 high-pressure fuel injection pump used on the Cummins 6.7L ISB diesel engine, found primarily in RAM 2500/3500 pickups (2007.5-2018) and some industrial/agricultural applications.

Here’s a detailed breakdown of what you need to know about this critical component:

A failing CP3 pump can cause severe and expensive downstream damage. Watch for:

Low-Pressure Fuel Supply Issues: A failing in-tank lift pump or clogged filter starving the CP3 of adequate fuel/lubrication is the #1 cause. The CP3 uses diesel for both fuel and internal lubrication.

Fuel Contamination: Water or abrasive particles in the fuel.

Extended Oil Change Intervals: On the Cummins, the CP3 is gearbox-driven and lubricated by engine oil. Poor quality or old engine oil can accelerate pump wear.

High Mileage: Normal wear and tear after 150,000-250,000+ miles.

Here is a detailed breakdown focused on the CP3 for the Cummins 6.7L.

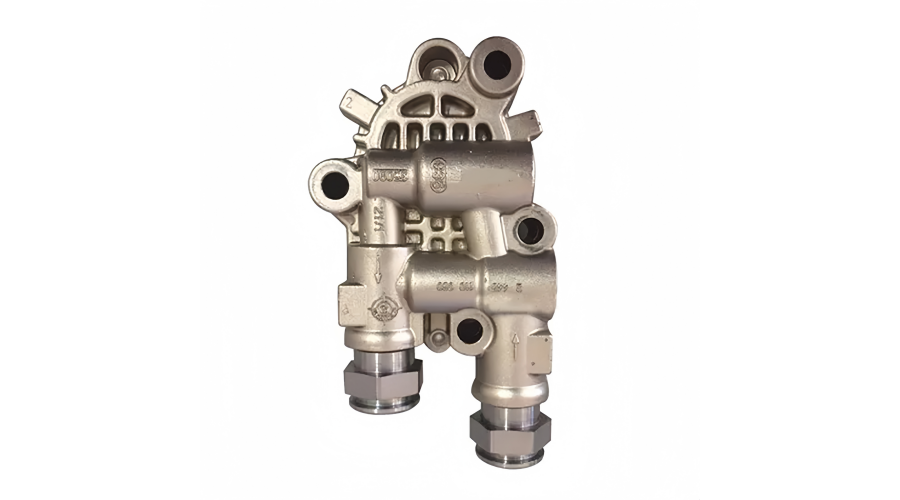

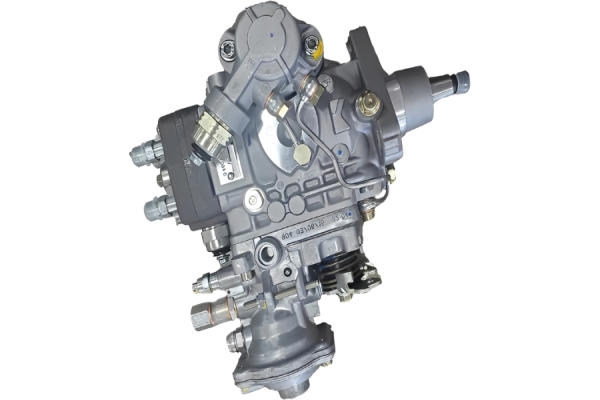

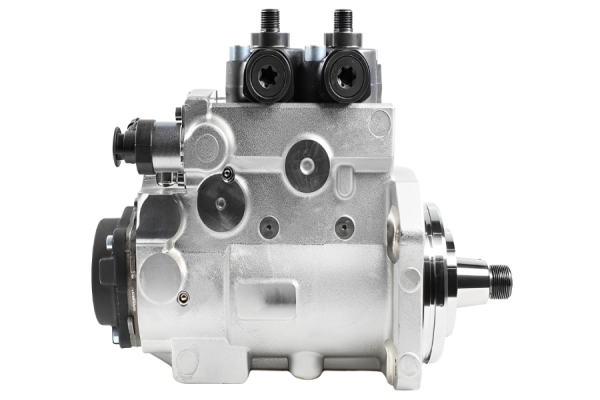

I. Structural Characteristics of the Bosch CP3 Pump

The CP3 is a radial piston distributor pump. Its design is distinct from earlier inline or rotary pumps and even from its successor, the CP4. Here's how it's built:

Radial Piston Arrangement: The core innovation. Instead of pistons in a line (inline pump) or a single piston, the CP3 has three or four small pistons arranged radially (like spokes on a wheel) around a central cam ring.

Two-Stage Pressure Increase:

First Stage (Gear Pump): A low-pressure integral gear pump at the inlet end. This pulls fuel from the tank, provides initial pressure (~5-10 psi), and supplies cooling/lubrication to the internal components.

Second Stage (Radial Piston): The high-pressure stage that takes the fuel from the gear pump and compresses it to common rail pressures.

Single High-Pressure Outlet: All radial pistons feed into a common central high-pressure chamber and then to a single outlet. This simplifies plumbing to the common rail.

Integrated Pressure Control Valve: The pump contains a fuel metering valve (often a solenoid-operated ZME or similar) and a pressure relief valve. These are electronically controlled by the Engine Control Module (ECM) to regulate the exact amount of fuel entering the high-pressure stage and to maintain the target rail pressure.

Gear-Driven (Cummins Specific): On the Cummins 6.7L, the CP3 is directly driven by the engine's gear train (located where a traditional mechanical injection pump would be). This provides a robust, positive-drive connection but means the pump is lubricated by engine oil, not just fuel.

Compact and Dense Construction: It is a heavy, precision-machined unit made of high-strength materials to withstand extreme internal pressures and rotational forces.

II. Advantages of the CP3 Design

These structural features translate into significant performance and reliability benefits, which is why it's so highly regarded, especially compared to the problematic CP4.

Exceptional Durability & Reliability: The CP3 is famously robust. Its radial piston design distributes loads evenly, reducing stress on individual components. It is far more tolerant of variations in fuel lubricity and minor fuel contamination than the CP4.

High Pressure Capability: Easily generates the pressures required for modern common rail systems (23,000+ PSI), enabling fine atomization for cleaner, more efficient combustion.

Smooth Operation & Reduced Noise: The multi-piston, radial design creates a more continuous flow of high-pressure fuel with less pulsation than single-piston designs, leading to quieter pump operation and reduced stress on the rail and injectors.

High Efficiency: The two-stage design is efficient across a wide range of engine speeds and fuel demands, contributing to overall fuel economy.

"Forgiving" Nature (Relative to CP4): This is its biggest advantage in the field. The CP3's internal clearances, lubrication scheme (engine oil on Cummins), and robust materials make it less prone to sudden, catastrophic failure from marginal fuel conditions—though it can still be destroyed by gross neglect.

III. Critical Installation & Priming Precautions

A failed installation can destroy a new CP3 in seconds. Follow these steps meticulously.

Pre-Installation:

Cleanliness is NON-NEGOTIABLE: Work in a clean area. Before opening any lines, clean the pump, its mating surface on the engine, and all surrounding areas thoroughly with brake cleaner. Any dirt entering the system is catastrophic.

Diagnose the Root Cause: NEVER install a new CP3 without first diagnosing and correcting what killed the old one.

MUST TEST/REPLACE the in-tank lift pump. Its failure is the #1 killer of CP3 pumps.

Inspect for Metal: If the old pump failed, cut open the fuel filter. If you find metal shavings, the entire high-pressure system (rail, lines, injectors) is contaminated and MUST be cleaned or replaced. Installing a new pump into a dirty system will cause immediate failure.

Replace All Filters: Install a new primary fuel filter/water separator and a new secondary fuel filter.

During Installation:

Lubricate the Pump: Before installing, fill the pump's fuel inlet port with clean, fresh diesel fuel. This prevents a dry start.

Sealing Surface: Ensure the engine block mating surface is perfectly clean and smooth. Use the correct new O-ring/gasket supplied with the pump.

Drive Gear Timing (CRITICAL for Cummins): The CP3 drive gear MUST be properly timed to the engine.

The pump and engine gear have alignment marks.

Procedure: Rotate the engine to Top Dead Center (TDC) on cylinder #1 compression stroke. Align the timing marks on the engine gear and the pump gear as specified in the service manual. An incorrectly timed pump will cause a no-start or poor running.

Torque Specifications: Use a torque wrench. Follow the manufacturer's specs for the mounting bolts and high-pressure line connections. Over- or under-torquing can cause leaks or damage.

Post-Installation Priming (THE MOST IMPORTANT STEP):

DO NOT CRANK THE ENGINE DRY.

Prime the Low-Pressure System: You must get fuel all the way to the inlet of the CP3.

On a Cummins Ram, you can often do this by cycling the ignition key to "ON" (not start) for 30 seconds, off for 10 seconds, and repeating 3-4 times. This activates the in-tank lift pump. Listen for it filling the filters and lines.

Alternatively, use a manual priming bulb or a diagnostic tool to command the lift pump.

Bleed the High-Pressure Side (Optional but Recommended): Loosen the high-pressure line connection at the common rail slightly (use a backup wrench!). Crank the engine in short bursts (10-15 seconds max) until you see a solid stream of fuel without air bubbles. Tighten the connection.

Final Start: Once primed, start the engine. It may crank slightly longer than normal. Immediately check for fuel leaks at all connections.

Post-Installation Check: Use a diagnostic scan tool to monitor desired vs. actual fuel rail pressure at idle and under light load. Ensure it is within specification.

Summary Checklist:

Diagnosed & Fixed root cause (lift pump, filters).

Checked for/cleaned up metal contamination in the entire system.

Cleaned all mating surfaces.

Lubricated (primed) the pump's inlet with diesel before installation.

Correctly timed the pump drive gear to the engine.

Torqued all fasteners to spec.

Primed the low-pressure system fully before cranking.

Bled air from the high-pressure line at the rail.

Verified no leaks and correct rail pressure with a scan tool.

Diesel pump supplier:

Rsolid parts is a professional manufacturer of diesel engine system components, providing high-quality and durable engine parts for different brands of engines, or producing fuel injectors and diesel pumps according to your requirements. The company is positioned as a professional and excellent supplier of automotive parts for foreign trade, including high-quality fuel injectors and diesel pumps. With years of international market experience, Rsolid has become a reliable partner for global customers seeking authentic Detroit products and comprehensive value-added services. The company is firmly committed to quality assurance, typically supported by international certifications commonly found in the automotive parts industry, ensuring that all parts undergo rigorous flow, pressure resistance, and leak integrity testing before being sold. Rsolid's business model typically includes maintaining a diverse and comprehensive inventory of OEM and high-end aftermarket parts, and offering cross compatible options to meet a wide range of applications and global customers from individual workshops to large fleet operators. If you are looking for diesel injectors or OEM engine diesel pumps, please feel free to contact us at any time .