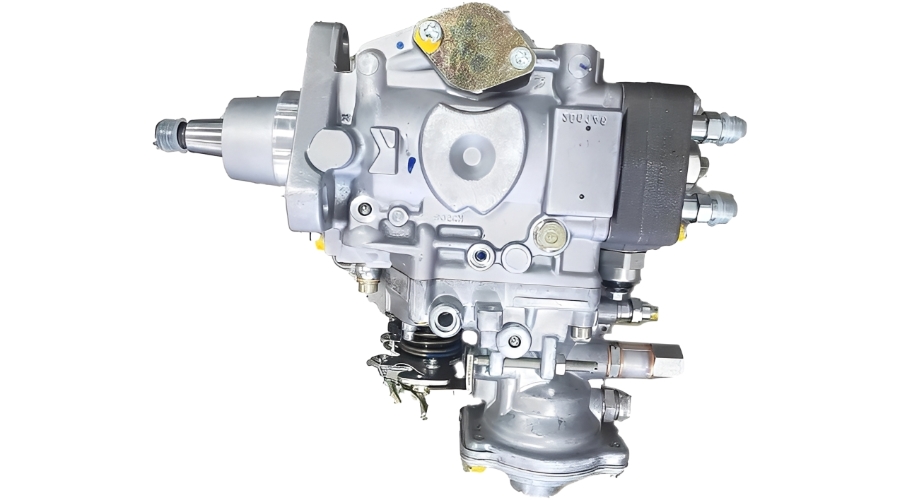

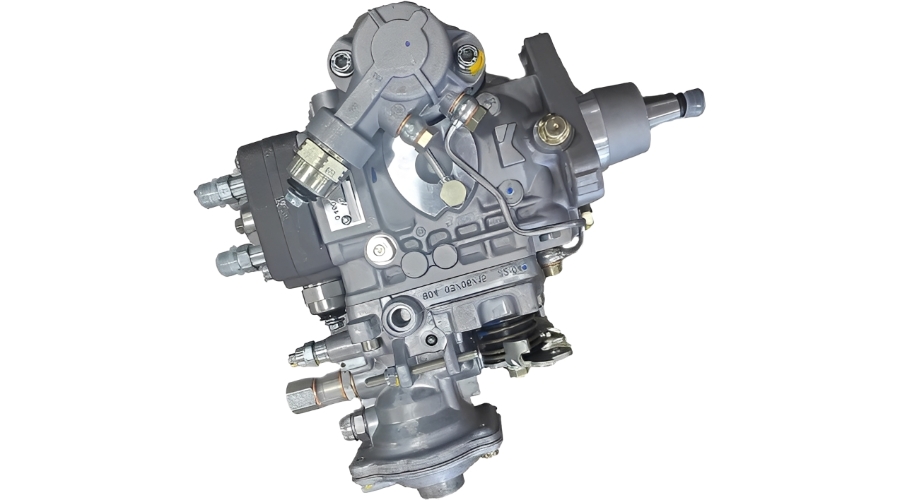

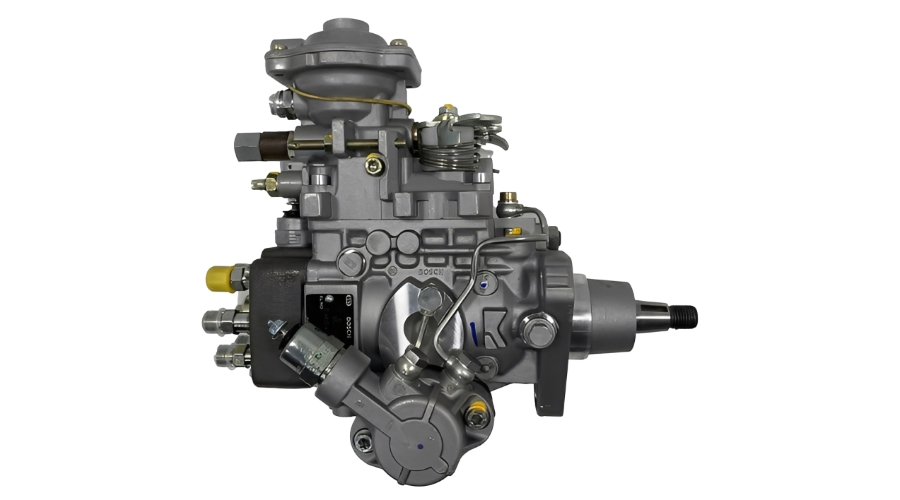

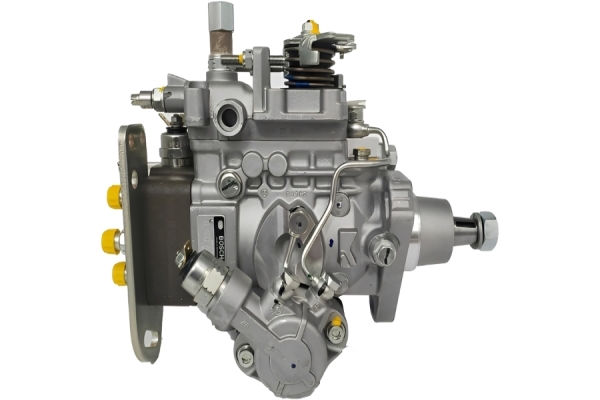

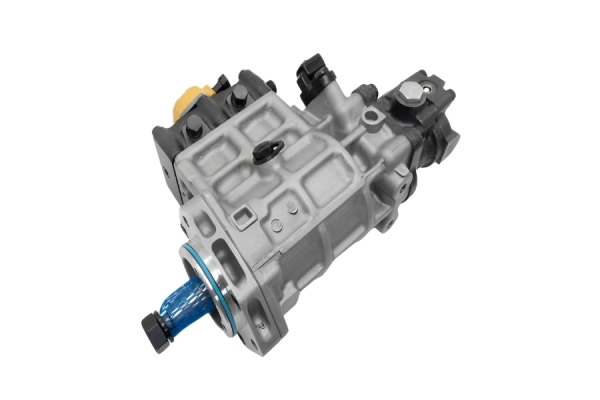

The Bosch diesel fuel injection pump with part number 0460426415 is most likely a Bosch VE (Verteiler-Einspritzpumpe, or "Distributor Injection Pump") type, a widely used rotary distributor pump in diesel engines. Below are its structural characteristics, advantages, and main applications:

1. Structural Characteristics of the Bosch VE Pump

The VE pump is a mechanically controlled rotary distributor pump with the following key components:

Key Components:

Hydraulic Head (Distributor Plunger) – Rotates to distribute fuel to each injector in firing order.

Cam Plate – Converts rotary motion into reciprocating motion to pressurize fuel.

Vane-Type Supply Pump – Draws fuel from the tank and supplies it to the injection pump.

Mechanical Governor – Controls engine speed by adjusting fuel delivery based on load.

Advance Mechanism – Adjusts injection timing for optimal performance at different RPMs.

Fuel Cut-Off Solenoid – Shuts off fuel flow when the engine is turned off.

Design Features:

Compact & Lightweight – Unlike inline pumps, the VE pump integrates all functions into a single unit.

Single Plunger Design – One plunger serves all cylinders, reducing complexity.

Self-Lubrication – Uses diesel fuel for internal lubrication.

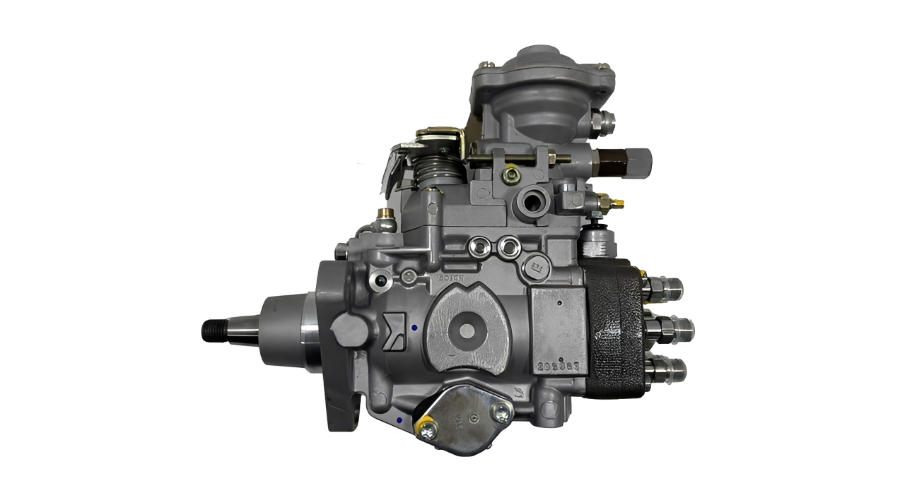

2. Advantages of the Bosch VE Pump

✅ High Reliability – Robust mechanical design with fewer moving parts than inline pumps.

✅ Precise Fuel Metering – Good balance between performance and fuel efficiency.

✅ Simple Maintenance – Easier to service than more modern electronic pumps.

✅ Wide Compatibility – Used in many light-duty and industrial diesel engines.

✅ Self-Adjusting Timing – Mechanical advance mechanism optimizes injection timing.

3. Main Application Equipment

The 0460426415 pump (or VE-type pumps in general) was commonly used in:

Automotive Applications:

Volkswagen (VW) / Audi – Older TDI and IDI diesel engines (e.g., 1.6L, 1.9L).

Peugeot / Citroën (XUD engines) – 1.8L, 1.9L diesel models.

Opel / Isuzu – Some 1.7L diesel engines.

Light Trucks & Vans – Smaller commercial vehicles with mechanical diesel engines.

Industrial & Agricultural Equipment:

Generators – Small to medium diesel gensets.

Tractors & Construction Machinery – Older diesel-powered equipment.

Marine Engines – Small marine diesel applications.

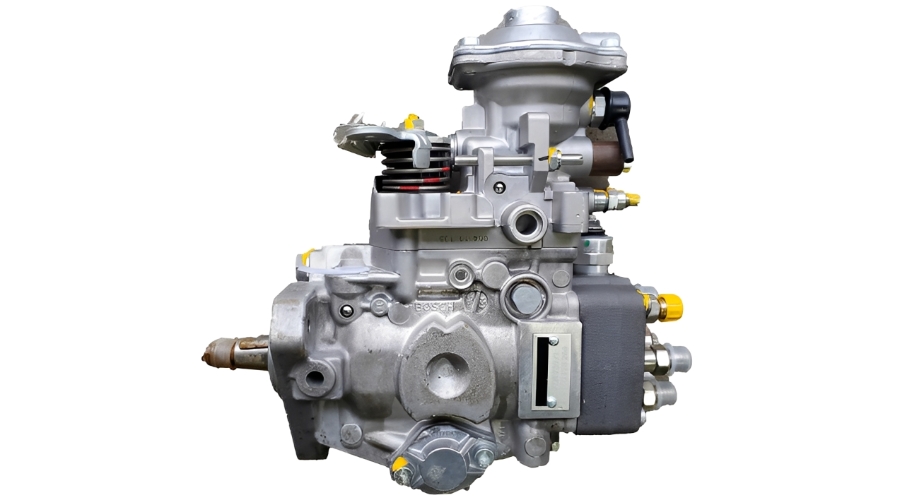

4. Limitations & Modern Replacements

❌ Not as Precise as Electronic Pumps – Lacks the fine-tuning capability of modern common rail or unit injector systems.

❌ Sensitive to Fuel Quality – Poor diesel or contaminants can cause wear.

🔄 Phased Out in Newer Engines – Replaced by electronically controlled systems (e.g., Bosch VP44, Common Rail).

Conclusion:

The Bosch 0460426415 (VE-type pump) is a mechanically controlled, rotary distributor pump known for its durability, simplicity, and widespread use in older diesel engines. It remains popular in classic diesel cars, light commercial vehicles, and industrial machinery but has been largely superseded by electronic injection systems in modern engines.

Proper daily maintenance of a Bosch VE-type diesel fuel injection pump (like 0460426415) is crucial for ensuring longevity, fuel efficiency, and smooth engine performance. Here are key maintenance suggestions:

1. Fuel Quality & Filtration

✅ Use Clean, High-Quality Diesel – Contaminated or low-grade fuel accelerates pump wear.

✅ Replace Fuel Filters Regularly – A clogged filter causes poor fuel flow, leading to pump starvation.

2. Lubrication & Leak Prevention

✅ Check for Fuel Leaks – Inspect pump seals, lines, and connections for leaks (prevents air ingress).

✅ Ensure Proper Lubrication – The VE pump relies on diesel fuel for lubrication.

3. Air Intrusion Prevention

✅ Bleed the Fuel System After Filter Changes – Air bubbles disrupt fuel delivery.

Procedure: Loosen the bleed screw on the pump, crank the engine until fuel flows without bubbles, then tighten.

✅ Check Fuel Tank Venting – A blocked vent can create a vacuum, reducing fuel flow.

4. Timing & Performance Checks

✅ Monitor Injection Timing – Worn timing belts or chains can misalign pump timing.

Symptoms of bad timing: Hard starting, excessive smoke, power loss.

✅ Listen for Unusual Noises – A failing VE pump may produce whining, knocking, or erratic idle.

✅ Watch for Smoke & Power Loss – Excessive black/white smoke indicates improper combustion.

5. Cold Weather Considerations

✅ Use Winter-Grade Diesel – Prevents waxing (fuel gelling) in cold climates.

✅ Consider a Fuel Additive – Anti-gel additives help in sub-zero temperatures.

✅ Avoid Extended Idling in Cold Weather – Promotes incomplete combustion and fuel wash-down.

6. Long-Term Storage Tips

🔹 If storing a vehicle with a VE pump:

Use a fuel stabilizer to prevent diesel degradation.

Run the engine periodically to keep seals lubricated.

Diesel Fuel pump Supplier:

Rsolid is a professional diesel fuel pump manufacturer provides high quality and durable diesel fuel pump replaements for different brands of engines or produce fuel pump according to your request. If you are looking for diesel pump or OEM engine parts, feel free to contact us.