The Delphi 28417048 (and pumps of its type) is not just a "spray pump"—it's a highly engineered rotary distributor-type diesel injection pump, often based on the Bosch VP44 design. Here are its key structural characteristics and the resulting advantages (and some inherent disadvantages).

1. Core Structural Characteristics

A. Basic Design Principle:

It is a single-plunger, high-pressure, distributor pump. One central plunger (piston) does all the high-pressure pumping for all engine cylinders, and a rotating distributor head directs this fuel to each injector in the correct firing order.

B. Key Internal Components & Structure:

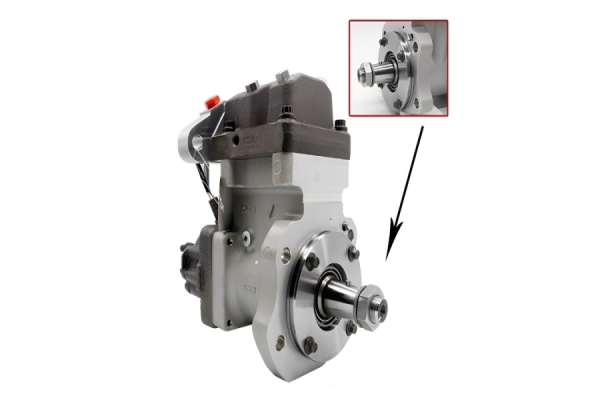

Drive Shaft: Driven by the engine's timing gears/belt. It rotates both the internal cam ring and the distributor rotor.

Cam Ring (Internal Cam): A stationary ring with internal lobes (one per cylinder). It's a defining feature.

Plunger (Roller/Shoe Assembly): The plunger is pushed radially outward by centrifugal force, with its rollers riding against the lobes of the internal cam ring. As the cam ring's high points push the plunger inward, it pressurizes the fuel. This is the radial-piston design.

Distributor Rotor: Connected to the drive shaft. It contains a single high-pressure chamber and an outlet port that aligns with individual fuel outlets to each injector as it rotates.

Electronic Control Unit (ECU) & Solenoid Valve: This is a major advancement.

The pump has a built-in ECU (often mounted on top). It receives signals from the engine ECU (vehicle's computer) regarding load, speed, temperature, etc.

A high-pressure solenoid valve (spill valve) controls the timing and duration of injection. By opening and closing this valve with extreme precision, the ECU controls exactly when injection starts and how much fuel is delivered.

Vane-Type Transfer Pump: Located at the input side. It draws fuel from the tank and supplies it at low pressure (4-10 bar) to the high-pressure pumping chamber. This ensures the main pump is always fed with fuel.

Timing Device: An electro-hydraulic or electronic advance mechanism that changes the relationship between the drive shaft and the cam ring to advance injection timing based on engine speed and load.

2. Key Advantages (Why This Design Was Widely Used)

These advantages stem directly from the structural features above:

High Pressure Capability: Capable of generating very high injection pressures (up to ~1,000 bar / 14,500 psi or more in later versions). This is critical for:

Fine Atomization: Breaks fuel into tiny droplets for cleaner, more complete combustion.

Reduced Emissions: Less soot (particulates) and improved efficiency.

More Power & Torque: Better fuel-air mixing allows for more efficient energy extraction.

Electronic Control (Major Advantage over Mechanical Pumps):

Precision: Enables extremely accurate control of injection timing and quantity on a stroke-by-stroke basis.

Adaptability: The ECU can adjust fueling for altitude, temperature, and turbocharger boost pressure.

Integration: Works seamlessly with the vehicle's main ECU for features like cruise control, anti-smoke maps, and torque management.

Compact & Lightweight Design:

A single pumping element serves all cylinders, making it much more compact and lighter than an in-line pump (which has one plunger per cylinder).

This saves space and weight in the engine bay.

Self-Lubrication & Cooling:

Good Performance Across the RPM Range:

3. Structural Vulnerabilities & Considerations (The Flip Side)

The structure also dictates its main weaknesses:

Extreme Dependency on Fuel Quality & Lubricity:

The high-precision components (plunger, distributor rotor) have tolerances measured in microns. Low-lubricity fuel (e.g., ultra-low sulfur diesel) or contaminants (water, dirt) cause rapid wear and seizure.

This is the #1 cause of failure. A lift pump (in-tank) failure that allows the VP44 to run dry will destroy it in seconds.

Complexity & Cost:

Heat Sensitivity:

Limited Ultimate Pressure vs. Common Rail:

While high-pressure for its era, it cannot match the flexibility and ultra-high, constant pressure (up to 2,500+ bar) of a modern Common Rail system. In Common Rail, pressure generation and injection are separate events, allowing for multiple injection events per cycle (pre, main, post).

Summary: Structural Philosophy

The Delphi 28417048 / VP44-type pump represents a brilliant transitional technology. It took the robust, simple rotary distributor concept and married it to electronic control, delivering a major leap in performance, efficiency, and emissions over purely mechanical pumps. Its structure is a compromise that favored:

High pressure and electronic precision over mechanical simplicity.

Compactness and integration over easy serviceability.

It paved the way for modern Common Rail systems but remains a solid, performance-oriented solution for the era of diesel engines it was designed for.

Always ensure it is fed with clean, high-quality fuel and that the vehicle's low-pressure fuel supply system (lift pump, filter) is in perfect condition to maximize its service life

Diesel injection pump supplier:

Rsolid is a professional diesel fuel injector manufacturer provides high quality and durable diesel fuel injector and Diesel injection pump replacements for different brands of engines or produce fuel injector according to your request. The company is positioned as a specialized and excellent supplier in the foreign trade of automotive components, including high-quality fuel injectors. With years of experience in the international market, Rsolid has established itself as a reliable partner for global clients seeking authentic Denso products and comprehensive, value-added services. The company operates with a strong commitment to quality assurance, often backed by international certifications common in the automotive parts industry,ensuring that all parts, undergo rigorous testing for flow rate, pressure endurance, and leak integrity before being offered for sale. Rsolid's business model would typically include maintaining a diverse and comprehensive inventory of both OEM and premium aftermarket parts, with cross-compatible options to cater to a wide range of applications and global clientele, from individual workshops to large fleet operators. If you are looking for diesel fuel injector or OEM engine fuel injector, feel free to contact us.