Faulty Crankshaft Position Sensor: A very common failure on these engines with similar symptoms.

Fuel Supply Issues: Clogged fuel filter, leaking pickup in the tank, failing lift pump, or air ingress in the fuel lines.

Wiring Harness Problems: The VP44's ECU communicates via a data bus (K-Line). Corrosion or broken wires in the harness between the pump and the main ECU are common, especially in the engine bay loom.

Fuel Quality: Poor fuel or water contamination can destroy the pump's internal components.

"New" vs. "Remanufactured":

Genuine New: Extremely expensive and often no longer available from Bosch/Isuzu.

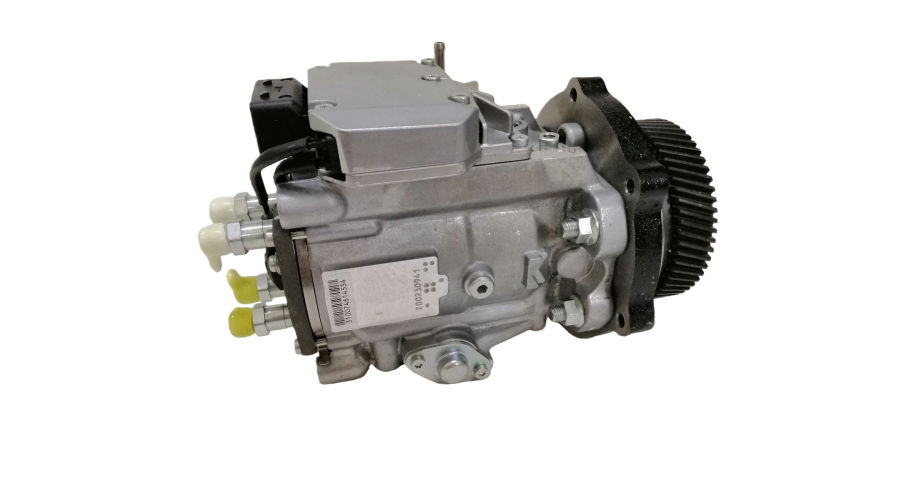

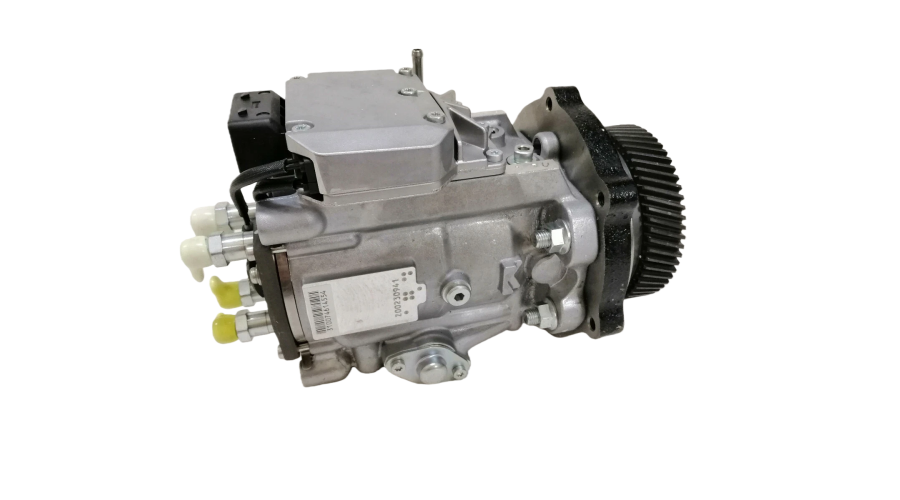

Quality Remanufactured: This is the standard repair path. A properly remanufactured pump will have new internal seals, wear components (roller ring, cam disc), a checked or replaced solenoid, and a recalibrated ECU. This is crucial. Simply swapping the mechanical part without the matched ECU will likely not work.

Part Number Verification: Double-check the number on your pump's identification tag. Variations exist (e.g., 109342-1006, -1008). Using the wrong variant can cause poor performance or communication errors. Also, verify your engine's exact model code (4JH1-TC****).

Installation & Calibration:

Timing is Critical: The pump must be installed with the correct static timing procedure (aligning marks on the pump gear and engine).

Electronic Adaptation: After installation, using a professional diagnostic scanner (like Tech2 or a high-end aftermarket tool) to perform "pump adaptation" or "coding" is often necessary for optimal operation.

Main Technical Advantages

Compared to its purely mechanical predecessors (like the VE pump), the VP44's advantages stem from its integration of high-pressure generation with electronic intelligence.

Electronic Control of Injection Timing and Quantity:

Dynamic, Adaptive Timing: The onboard ECU can adjust injection timing millisecond-by-millisecond based on engine load, speed, coolant temperature, and boost pressure. This optimizes power, fuel economy, and significantly reduces cold-start smoke and noise.

Precise Fuel Metering: Delivers the exact amount of fuel demanded by the driver's pedal andengine conditions, improving efficiency and responsiveness over mechanical governors.

Higher Injection Pressures:

Capable of generating soaring injection pressures (up to ~1000 bar / 14,500 psi). This is crucial for the direct injection (DI) 4JH1 engine, where fuel is sprayed directly into the combustion chamber. Higher pressure creates a finer fuel atomization, leading to cleaner, more complete combustion.

Enabler for Advanced Emission Control:

This was its primary raison d'être. The precise electronic control allowed manufacturers like Isuzu to meet increasingly stringent emission standards (Euro III / EPA Tier 2 equivalents) without sacrificing drivability. It managed the combustion process to reduce particulate matter (soot) and NOx at their source.

Integrated Design & Communication:

Self-Contained ECU: The control unit is mounted directly on the pump, surviving the harsh under-hood environment (vibration, temperature) better than a separate module.

CAN-Bus Communication (on later models): The pump's ECU doesn't work in isolation. It communicates with the vehicle's main ECU over a data network, sharing information and receiving commands (e.g., from the cruise control or anti-theft system).

Improved Cold Start & Altitude Performance:

The ECU can automatically advance timing and increase fuel quantity during cold starts. It can also compensate for atmospheric pressure changes (altitude), maintaining optimal performance where a mechanical pump would lose power.

Key Application Equipment It Enabled/Required

The VP44 didn't just plug into an old mechanical engine. It was the centerpiece of a new, integrated Electronic Diesel Control (EDC) system. Here's the key equipment it works with:

1. Sensor Suite (The "Eyes and Ears" for the Pump ECU):

Crankshaft Position Sensor (CKP): Critical. Provides engine speed and piston position.

Camshaft Position Sensor (CMP): Provides cylinder identification (for sequential timing).

Coolant Temperature Sensor (ECT): For cold-start enrichment and timing correction.

Boost Pressure Sensor (MAP): Informs the ECU of turbocharger boost to optimize fuel and timing under load.

Accelerator Pedal Position Sensor (APP): An electronic "drive-by-wire" throttle, sending a voltage signal instead of a cable pull.

Fuel Temperature Sensor (often in the pump): Corrects for fuel density changes.

2. Actuators & Ancillary Components:

In-Check Solenoid Valve: The VP44's primary actuator. The ECU pulses this high-speed solenoid to control the precise moment fuel injection begins (timing) and ends (quantity).

Electric Lift Pump: Typically in the fuel tank. Provides a constant, air-free supply of fuel at low pressure (3-5 bar) to the suction side of the VP44. This is critical; the VP44's internal vane-type transfer pump is not designed to pull fuel over long distances. Failure of the lift pump is a common cause of premature VP44 failure.

3. Control & Communication Network:

Vehicle Main ECU (Engine Control Module): The master computer. It processes inputs from other systems and sets overall torque and speed targets for the VP44's ECU.

Diagnostic Port (e.g., OBD-II / J-OBD): Allows technicians to read fault codes, view live data (actual injection timing, fuel quantity, sensor values), and perform calibrations.

4. Supporting Fuel System:

High-Precision Injectors: Designed to handle the 1000+ bar pressure. Typically, Bosch DLLA-type pencil injectors with very tight tolerances.

Advanced Fuel Filter/Water Separator: Even more critical than on older systems. A single instance of contaminated fuel can destroy the high-precision plunger and bore inside the VP44 in minutes.