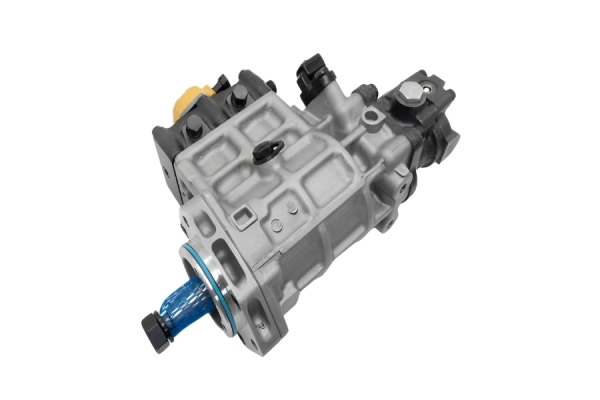

Type: Gear pump (positive displacement).

Drive: Typically driven by a gear off the engine's accessory drive system.

Includes: The assembly generally consists of the pump housing, gears, drive shaft, seals, gaskets, and mounting flange. It may come as a complete unit or a repair kit.

Important: Always verify the exact configuration (rotation, inlet/outlet port orientation, drive coupling) matches your specific engine model and serial number, as there can be variations.

This is not a simple pump. It's a heavy-duty, positive displacement, gear-driven pump designed for relentless duty in extreme conditions.

Core Structural Characteristics:

Gear Design: Utilizes herringbone or spur gears machined from hardened steel. Herringbone gears are common in high-pressure applications as they cancel out axial thrust, reducing bearing load and wear, and operate more quietly.

Housing: Made of cast iron or high-strength aluminum alloy, providing immense rigidity to withstand internal pressures and prevent distortion. It features precisely machined bores for the gears and journals.

Drive Mechanism: Features a robust splined or keyed steel drive shaft, directly coupled to the engine's gear train. This provides positive, non-slip drive but also means the pump's lifecycle is tied to engine runtime.

Sealing System:

Shaft Seals: Multi-layered lip seals or mechanical face seals to handle high-pressure fuel and prevent leaks along the drive shaft.

Gaskets: Heavy-duty flange gaskets for the mounting surface and cover plates.

Internal Clearances: Machined to exacting micron-level tolerances. The efficiency of a gear pump comes from the minimal clearance between the gear teeth and the housing. These tight clearances are maintained through hardened materials and precise engineering.

Integrated Porting: The inlet and outlet ports are cast directly into the housing, providing a direct, sturdy path for fuel. They are often threaded for standard NPTF or SAE ORB fittings.

Inherent Advantages of This Design for Heavy-Duty Applications:

Extreme Durability & Simplicity: Fewer moving parts than vane or rotor pumps. The solid gear and housing construction can tolerate fuel contamination better than more delicate pump types and has a very long service life under proper conditions.

Positive Displacement & Consistent Flow: It moves a fixed amount of fuel per revolution. Flow is directly proportional to engine speed, which is ideal for an engine-driven application. It provides a strong, steady flow that minimizes vapor lock and ensures fuel supply at all RPMs.

High Pressure Capability: Naturally capable of generating the high supply pressures (typically 50-150 PSI) required by the downstream PT or common rail injection systems of large diesels.

Self-Priming: The tight meshing of gears creates an excellent vacuum on the inlet side, allowing it to draw fuel effectively from tanks located below or far from the engine.

Tolerance to Viscosity Changes: Performs reliably across a wide range of fuel viscosities (from summer to winter blends), crucial for engines operating in varying climates.

Disadvantage (and a key maintenance point):

Sensitivity to Dry Running: The tight tolerances and metal-on-metal lubrication require fuel for cooling and lubrication. Extended dry running can destroy the pump in seconds. This is why priming the fuel system after filter changes is critical.

Part 2: The QSK19 Engine: Application Scenarios & Equipment

The Cummins QSK19 is not just an engine; it's a 19-liter, 6-cylinder, quad-turbocharged, aftercooled Tier 4 Final / Stage V powerhouse representing the pinnacle of high-density power and torque for the most demanding applications.

Core Structural & Technological Advantages:

Quad-Turbo Sequential System: This is its defining feature. Four small turbos engage sequentially, eliminating turbo lag. It provides an incredibly fast response (<1 second to full torque), phenomenal power density (high horsepower from a relatively compact block), and exceptional fuel efficiency across the entire operating range.

High-Pressure Common Rail (HPCR) Fuel System: The pump we discussed (4306515) feeds this system. The HPCR system provides multiple injections per cycle, enabling ultra-clean combustion (meeting stringent emissions standards), reduced noise, and improved power.

Modular Design: Key components (like the fuel pump, turbochargers, and the Common Accumulator Rail (Cummins CAPS™ system) are designed as replaceable modules, drastically reducing service and overhaul time.

Robust Base Engine: Built on the legendary K19 block with a forged steel crankshaft, inductively hardened cylinder liners, and high-strength alloy heads. It's designed for a 30,000+ hour B10 life in continuous operation.

Conclusion:

The 4306515 gear pump is a masterpiece of rugged, deterministic engineering—built to be an utterly reliable workhorse. It is the perfect low-pressure heart to feed the technological marvel that is the QSK19—an engine that combines brute-force mechanical strength with cutting-edge turbocharging and electronic control. Together, they form a power system trusted to run the world's most critical and punishing industrial machinery .

Where to buy:

Rsolid is a professional manufacturer of diesel engine system components, providing high-quality and durable engine parts for different brands of engines, or producing fuel injectors and diesel pumps according to your requirements. The company is positioned as a professional and excellent supplier of automotive parts for foreign trade, including high-quality fuel injectors and diesel pumps. With years of international market experience, Rsolid has become a reliable partner for global customers seeking authentic Detroit products and comprehensive value-added services. The company is firmly committed to quality assurance, typically supported by international certifications commonly found in the automotive parts industry, ensuring that all parts undergo rigorous flow, pressure resistance, and leak integrity testing before being sold. Rsolid's business model typically includes maintaining a diverse and comprehensive inventory of OEM and high-end aftermarket parts, and offering cross compatible options to meet a wide range of applications and global customers from individual workshops to large fleet operators. If you are looking for diesel injectors or OEM engine diesel pumps, please feel free to contact us at any time .