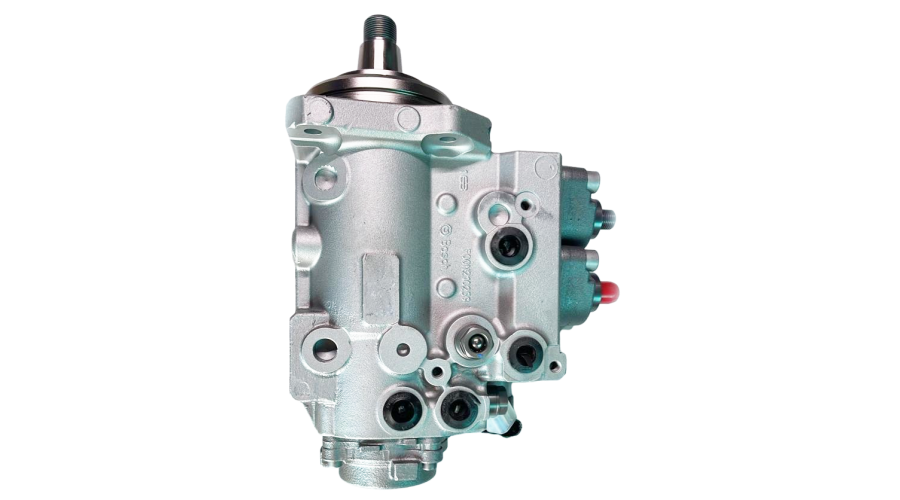

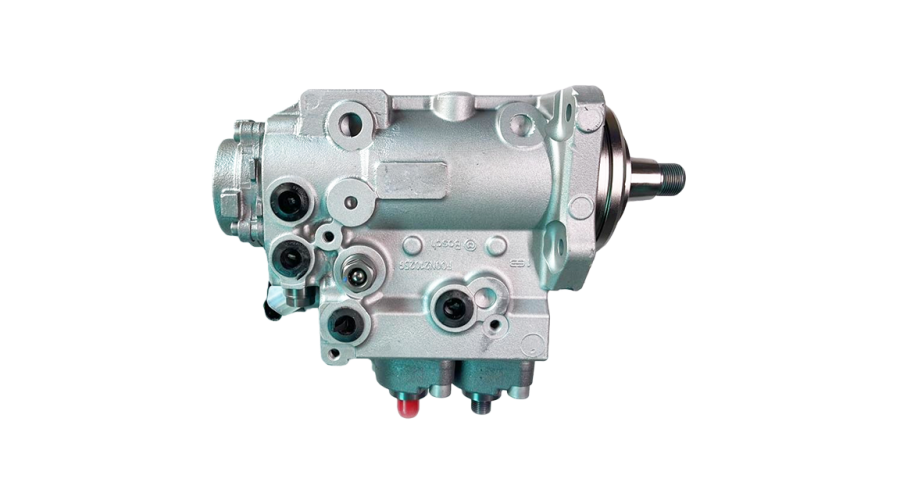

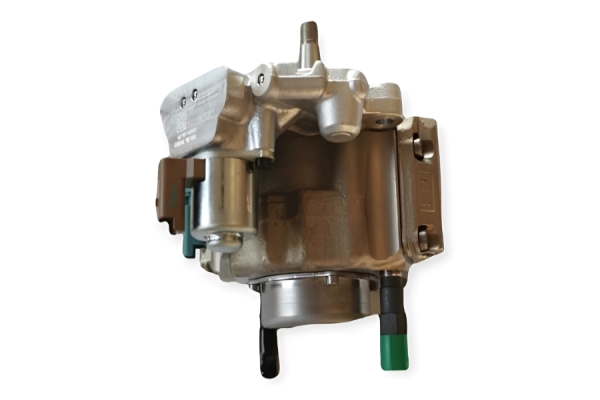

RA4720901550 Part Identification & Core Function:

Application: Specifically designed for Detroit Diesel DD15 and DD16 heavy-duty truck engines.

Material: Aluminum Housing - This makes it a modern, lightweight, high-pressure pump.

Function: It is the High-Pressure Fuel Pump (HPFP). This is the heart of the engine's fuel injection system.

Critical Importance to the Truck Engine

This is not a minor component; it is absolutely essential. Its primary job is to take fuel from the low-pressure fuel supply system and ramp it up to extremely high pressures (often exceeding 30,000 PSI) required by the common rail fuel system.

Common Symptoms of a Failing DD15/DD16 Fuel Injection Pump

If you're looking at this part, you might be experiencing:

Hard Starting or No Start: Lack of high-pressure fuel.

Loss of Power: Inability to deliver required fuel pressure under load.

Engine Misfires or Rough Running.

Increased Fuel Consumption.

Fuel Leaks from the pump area.

Diagnostic Trouble Codes (DTCs) related to low fuel rail pressure (e.g., P0087, P0088, P0093, or Detroit Diesel-specific codes like SPN 98/FMI).

1. Main Technical Advantages & Application Scenarios/Equipment

Technical Advantages of the DD15/DD16 High-Pressure Fuel Pump (HPFP):

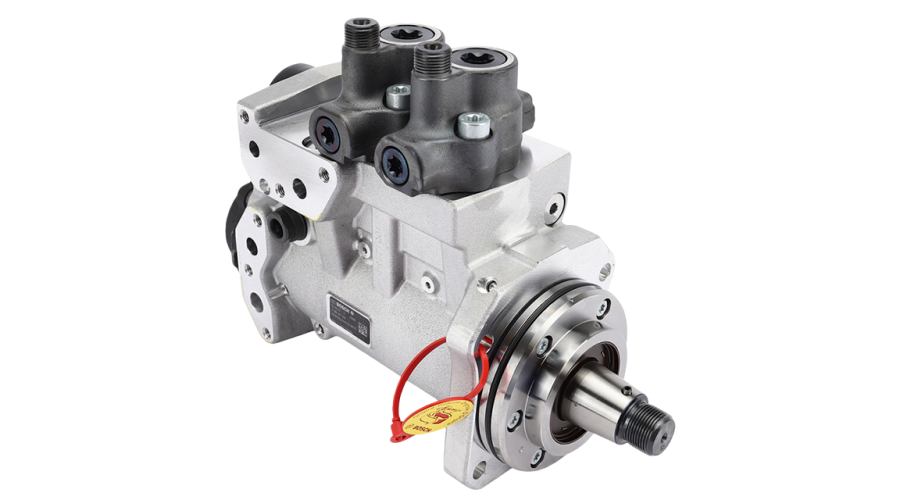

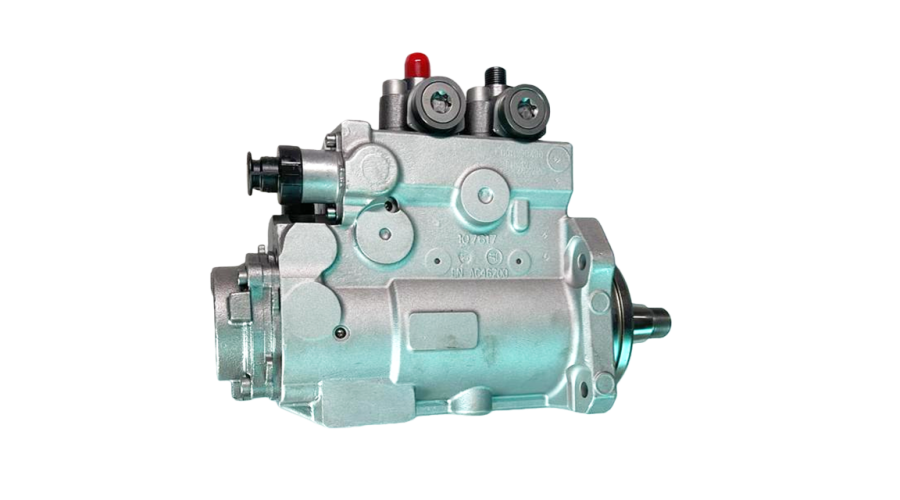

This is not a "jet pump" in the traditional sense (like a water eductor). It is a swashplate-type axial piston pump, which is a high-precision, high-endurance design. Its key technical advantages stem from this design:

High Pressure & High Flow with Compact Design: The axial piston/swashplate design can generate the extreme pressures (30,000+ PSI) required for modern common-rail injection while maintaining a high flow rate to feed a large-displacement 6-cylinder engine. Its aluminum housing keeps it relatively lightweight.

Excellent Efficiency & Controllability: The pump's output is precisely regulated by an Electronic Pressure Regulator (EPR) or a flow control valve directly commanded by the engine's ECM. This allows for optimal pressure for any given engine speed and load, improving fuel economy and reducing emissions.

Robustness for Heavy-Duty Use: Designed for the continuous, high-stress operation of line-haul trucking. The internal components (pistons, swashplate, bearings) are hardened and built to last hundreds of thousands of miles with proper maintenance.

Integration with the DD Platform: It's specifically engineered for the Detroit Diesel Amplified Common-Rail System (ACRS) used on DD13, DD15, and DD16 engines. This system uses pressure amplification within the injectors themselves, allowing the pump to operate at very high but slightly more manageable pressures, improving reliability.

Primary Application Scenarios & Equipment:

This pump is used exclusively in heavy-duty on-highway truck engines.

Primary Application:

Equipment Typically Found In:

Class 8 Line-Haul Trucks: Freightliner Cascadia, Western Star 5700/6900 (the most common application).

Heavy-Duty Vocational Trucks: For logging, heavy haul, or dump trucks equipped with a DD15/16.

Some Modern Fire Apparatus & Specialized Haulers that specify this engine platform.

Operational Scenario: It is mission-critical for long-distance, high-load transportation. Failure on the road leads to immediate, costly downtime.

2. Daily Preventive Maintenance & Replacement Precautions

Daily/Preventive Maintenance (The Best Defense):

The #1 cause of HPFP failure is fuel contamination (dirt, water, microscopic particles).

Fuel Filter Changes – NON-NEGOTIABLE: Adhere strictly to the OEM service intervals. For DD15/16 engines, this is typically every 30,000 - 45,000 km/miles, but check your manual. Use only high-quality, OEM-recommended filters (e.g., Fleetguard, Donaldson, Detroit Diesel Genuine). Cheap filters are a false economy.

Water-in-Fuel (WIF) Sensor: Pay attention to the WIF warning light on your dash. Drain the water separator as soon as it illuminates. Water is a lubricity killer and causes catastrophic internal corrosion in the HPFP.

Fuel Quality: Purchase fuel from reputable, high-volume truck stops. Consider using API CK-4/FA-4 certified oils and diesel with adequate lubricity additives. In some regions, a supplemental lubricity additive can be insurance, but consult your engine manufacturer first.

Regular Fuel System Inspections: During oil changes, visually check for any fuel leaks around the pump, connections, and lines. A small leak can indicate a failing seal.

Listen for Unusual Noises: A healthy pump has a distinct mechanical hum. A loud whining, knocking, or grinding noise from the pump area is a red flag for impending failure.

Critical Precautions for Replacing the Jet Pump (HPFP):

Replacement is a major repair. Doing it correctly is paramount.

Before Installation:

Diagnose Thoroughly: Confirm the pump is the culprit. Use diagnostic software to check fuel pressure commands vs. actual readings. Rule out issues with the pressure regulator, suction line restrictions, or ECM problems.

Purchase the Right Kit: Ensure you have all necessary parts: the pump, new seals/gaskets, new mounting bolts (they are often torque-to-yield and must be replaced), and new fuel supply lines if the old ones are compromised.

Cleanliness is GOD: Work in a clean area. Before opening any connections, use brake cleaner and compressed air to thoroughly clean the pump and its mounting area on the engine. The goal is zero dirt ingress.

During Installation:

Prime, Prime, Prime: DO NOT allow the new pump to run dry. Fill the pump housing with clean, fresh diesel fuel before installation. After installation, use the hand primer pump (on the fuel filter housing) to prime the entire low-pressure system until firm resistance is felt. This prevents dry-start damage.

Torque Specifications: Always use a torque wrench. Follow the manufacturer's exact sequence and torque specs for mounting bolts. Overtightening can warp the aluminum housing; undertightening will cause leaks.

Contamination Protocol (MOST IMPORTANT): If the old pump failed due to internal wear or breakage (e.g., sending metal debris):

You MUST flush the entire low-pressure fuel system: This includes dropping and cleaning the fuel tanks, replacing all fuel lines from the tank to the pump, and replacing the primary and secondary fuel filters.

Inspect/Replace the Common Rail and Injectors: Metal debris will travel to the rail and injectors. They must be inspected by a specialist or replaced to avoid immediate failure of the new pump.

After Installation:

Leak Check: Before starting, double-check all connections. After starting, run the engine at idle and inspect for leaks.

Clear Codes & Perform Calibration: Use diagnostic software (DDDL or equivalent) to clear all existing fault codes. Some installations may require a "pump learn" or calibration procedure so the ECM recognizes the new pump's flow characteristics.

Test Drive & Monitor: Perform a test drive, monitoring for power and smooth operation. Keep an eye on fuel pressure parameters via the dash display or diagnostic tool for the first few hundred miles.

Where to buy:

Rsolid is a professional manufacturer of diesel engine system components, providing high-quality and durable engine parts for different brands of engines, or producing fuel injectors and diesel pumps according to your requirements. The company is positioned as a professional and excellent supplier of automotive parts for foreign trade, including high-quality fuel injectors and diesel pumps. With years of international market experience, Rsolid has become a reliable partner for global customers seeking authentic Detroit products and comprehensive value-added services. The company is firmly committed to quality assurance, typically supported by international certifications commonly found in the automotive parts industry, ensuring that all parts undergo rigorous flow, pressure resistance, and leak integrity testing before being sold. Rsolid's business model typically includes maintaining a diverse and comprehensive inventory of OEM and high-end aftermarket parts, and offering cross compatible options to meet a wide range of applications and global customers from individual workshops to large fleet operators. If you are looking for diesel injectors or OEM engine diesel pumps, please feel free to contact us at any time .