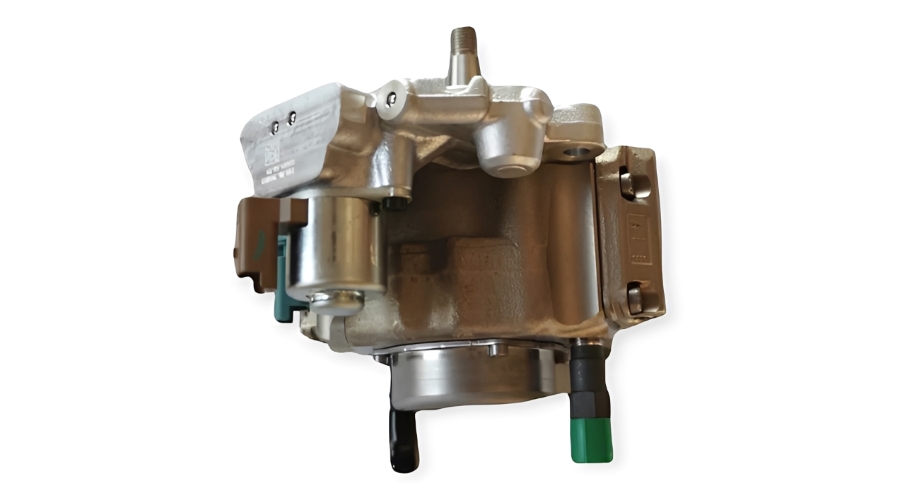

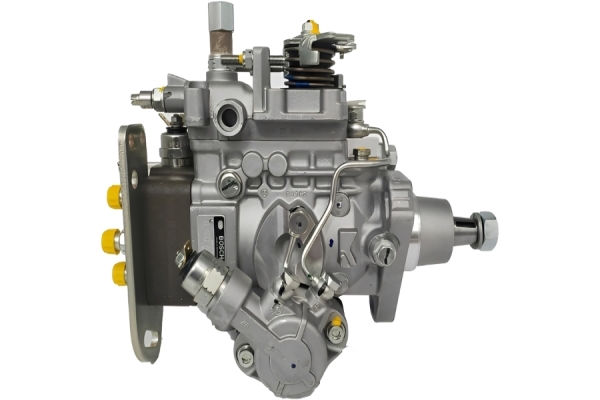

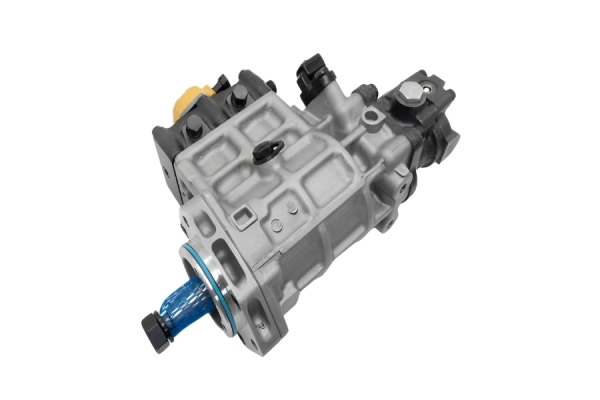

Detailed Analysis of Bobcat Fuel Pump (Part #7256789)

1. Structural Characteristics

The Bobcat 7256789 fuel pump is an electric in-tank fuel pump designed for efficient fuel delivery in heavy-duty equipment. Its key structural features include:

Pump Type: Brushless DC electric motor (for longer lifespan and reduced wear).

Housing Material: Durable aluminum or high-grade plastic (resistant to fuel corrosion and vibration).

Filter Screen: Integrated fine mesh pre-filter to prevent debris from entering the fuel system.

Pressure Regulator: Built-in regulator to maintain consistent fuel pressure (typically ~50-60 PSI for common rail diesel systems).

Connector & Wiring: Sealed electrical connector (weatherproof and resistant to oil/fuel exposure).

Mounting Style: Direct in-tank installation (submerged in fuel for cooling and lubrication).

2. Technical Advantages

High Efficiency: Optimized flow rate (varies by model, typically 30-50 GPH) ensures sufficient fuel supply under heavy loads.

Durability: Designed for rugged environments (resistant to dust, moisture, and temperature extremes).

Precision Fuel Delivery: Maintains stable pressure for Doosan D34 engines, ensuring optimal combustion and reduced emissions.

Low Noise & Vibration: Brushless motor design minimizes operational noise compared to traditional fuel pumps.

Compatibility: Direct-fit replacement for multiple Bobcat and Doosan-powered machines.

3. Application Scenarios

This fuel pump is used in skid steers, compact track loaders, and utility vehicles operating in:

Construction sites (high dust/debris environments)

Agriculture & Landscaping (variable load conditions)

Snow removal & Road maintenance (cold-weather operation)

Industrial material handling (continuous heavy-duty cycles)

4. Compatible Equipment Models

| Machine Type | Models |

|---|

| Skid Steer Loaders | S740, S750, S770, S850 |

| All-Wheel Steer | A770 |

| Toolcat Utility | T740, T750, T770, T870 |

| Versa Handlers | V519, V723 |

| Doosan Engines | D34 (used in some Bobcat machines) |

Conclusion

The Bobcat 7256789 fuel pump is a high-performance, durable component essential for maintaining fuel system reliability in demanding conditions. Its brushless motor, corrosion-resistant housing, and precise pressure regulation make it ideal for Bobcat’s heavy-duty equipment lineup.

Common Problems & Reasons for Bobcat Fuel Pump (7256789) Failure

1. Common Failure Symptoms

Engine Cranking But Not Starting → Fuel pump not delivering fuel.

Loss of Power Under Load → Insufficient fuel pressure/volume.

Engine Stalling or Surging → Intermittent fuel supply.

Whining or Humming Noise from Fuel Tank → Pump motor struggling.

Check Engine Light (Fuel Pressure Codes) → P0087 (low pressure) or P0088 (high pressure).

2. Root Causes of Failure

| Problem | Likely Cause |

|---|

| No Fuel Delivery | - Burned-out pump motor (electrical failure)

- Clogged fuel filter/screen

- Blown fuse or relay issue |

| Low Fuel Pressure | - Worn pump internals (brushes/motor)

- Faulty pressure regulator

- Leaking fuel line or injector |

| Overheating & Early Failure | - Running on low fuel (pump not submerged)

- Contaminated fuel (water/dirt)

- Excessive voltage (bad wiring/alternator) |

| Intermittent Operation | - Corroded electrical connectors

- Damaged wiring harness

- Weak fuel pump relay |

Maintenance & Prevention Tips

1. Regular Inspection & Care

✅ Check Fuel Quality – Avoid dirty or watered-down diesel; use a fuel conditioner if needed.

✅ Keep Fuel Tank Above 1/4 Full – Prevents pump overheating (fuel cools the motor).

✅ Replace Fuel Filters – Clogged filters force the pump to work harder (follow Bobcat’s service intervals).

✅ Inspect Electrical Connections – Look for corrosion, loose wires, or damaged connectors.

2. Troubleshooting Steps Before Replacement

🔧 Test Fuel Pressure – Use a gauge (should be ~50-60 PSI for D34 engines).

🔧 Check Voltage at Pump – Should be 12V+ when ignition is on.

🔧 Listen for Pump Prime – A 2-3 second hum at startup indicates it’s working.

🔧 Swap Relay/Fuse – Rule out electrical issues before condemning the pump.

3. When to Replace the Pump

⚠️ If:

Final Recommendations

Use OEM or High-Quality Aftermarket Pumps – Rsolid

Avoid Ethanol Blends – Can degrade seals in diesel systems.

Store Machines Properly – If unused for long periods, add fuel stabilizer.