Primary Application: Toyota/Lexus 2GR-FE and 2GR-FSE Engines

The Denso 6261-11-3200 injector is most famously used in Toyota and Lexus vehicles equipped with the 3.5L V6 "2GR" engine, specifically:

2GR-FE (Port Fuel Injection): This is the standard version of the engine.

2GR-FSE (Direct and Port Fuel Injection - D4-S): On this engine, the 6261-11-3200 injector is used as the port injector (the secondary injector that sprays fuel into the intake port, not directly into the cylinder).

Common Vehicles that use this injector include:

Toyota:

Camry (2007-2017)

Avalon (2005-2012)

Highlander (2008-2013)

Sienna (2007-2010)

RAV4 V6 (2006-2012)

Venza (2009-2015)

Lexus:

ES 350 (2007-2012)

RX 350 (2007-2012)

IS 350 (2006-2013)

GS 350 (2007-2012)

Important Note: Always confirm this is the correct part for your specific Vehicle Identification Number (VIN). There can be variations even within the same model year.

2. Technical Specifications

Type: Electromagnetic, saturated-type port fuel injector.

Impedance: High Impedance (typically 12-16 Ohms). This is a crucial specification. High-impedance injectors can be driven directly by most aftermarket ECUs without the need for a peak-and-hold driver box, making them popular for engine swaps and performance projects.

Flow Rate: Approximately 315 cc/min @ 43.5 psi (3.0 Bar). This is a standard flow rate for many naturally aspirated V6 applications.

3. Why This Injector is Well-Known

This injector has gained significant popularity beyond just replacement use for a few key reasons:

Engine Swaps: The 2GR-FE engine is a very popular swap into other Toyota vehicles (like the MR2, Celica, Lotus Elise/Exige) and other rear-wheel-drive cars. The stock 6261-11-3200 injectors are often retained as they are perfectly sized for the naturally aspirated 3.5L engine.

Aftermarket Management: Because they are robust, reliable, and high-impedance, they are a favorite for use with standalone engine management systems (like Haltech, Link, AEM) in various custom and performance applications.

Availability: As a very common OEM part, they are widely available new, refurbished, and used.

Detailed Description: Denso 6261-11-3200 Fuel Injector

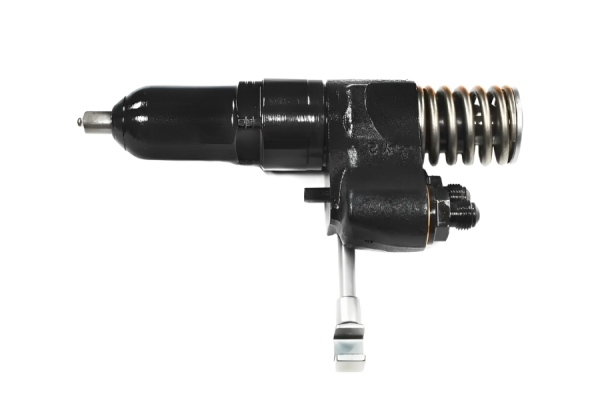

The Denso 6261-11-3200 is a high-precision electromechanical component responsible for metering and atomizing fuel for combustion. Its design embodies the principles of reliability, efficiency, and precision that Denso is known for.

1. Structural Features & Design

The injector's structure can be broken down into several key components, each serving a critical function:

Solenoid Actuator (Top): This is the electromagnetic component. When the Engine Control Unit (ECU) sends a pulsed electrical signal, it energizes the solenoid coil, creating a magnetic field that pulls a plunger upward.

Plunger and Needle Valve: The plunger is directly connected to a precisely machined needle valve. When the solenoid is energized, the plunger lifts, pulling the needle valve off its seat and opening the flow path for fuel.

Filter Basket (Inlet): Located at the fuel inlet, this fine mesh screen filters out any microscopic contaminants in the fuel that could clog the injector's precise internal passages. This is a critical first line of defense.

Multi-Hole Disc (Outlet - Not Pintle): Unlike older-style pintle injectors, this model uses a laser-drilled multi-hole disc at the tip. This disc has multiple meticulously sized holes that create a specific spray pattern (e.g., a conical spray) for optimal atomization.

High-Impedance Coil: The internal electrical coil has a high resistance (12-16 ohms). This design allows the ECU to control it with a simple saturated driver circuit, making it electrically robust and simpler to implement than low-impedance injectors.

O-Rings and Insulator: The body features grooves for upper and lower viton O-rings that seal the fuel system. A plastic insulator surrounds part of the body to dampen vibration and prevent heat transfer from the engine to the injector body.

2. Technical Advantages

The design of this injector translates into several significant performance benefits:

Superior Atomization: The multi-hole disc is its key advantage. It breaks fuel into a fine, consistent, and conical mist, vastly improving the surface area of the fuel droplets. This leads to more complete and efficient combustion, resulting in:

Precision Metering and Fast Response: The injector operates with extreme speed and accuracy, opening and closing in milliseconds. It can deliver the exact amount of fuel commanded by the ECU for any given engine load and RPM, ensuring the air-fuel ratio is always near the ideal stoichiometric point (14.7:1).

High Reliability and Durability: Denso's use of high-quality materials and manufacturing tolerances ensures a long service life. The components are designed to withstand high fuel pressures, extreme engine temperatures, and constant cycling.

Electrical Simplicity (High-Impedance): The high-impedance design means it draws less current and can be driven directly by most automotive ECUs and aftermarket engine management systems without requiring additional, expensive peak-and-hold driver modules. This makes it a favorite for engine swaps and tuners.

Consistent Flow Matching: OEM-grade injectors like this are flow-matched to very tight tolerances. This means all injectors in a set will flow within 1-2% of each other, ensuring smooth engine operation and balanced cylinder performance.

3. Daily Maintenance & Longevity Recommendations

Fuel injectors are wear items but are designed for long life. Proper maintenance is key to preventing issues like clogging, poor performance, and failure.

Daily/Regular Use Best Practices:

Use High-Quality Fuel: Purchase gasoline from reputable, top-tier retailers. These fuels contain detergent additives that help keep injector nozzles clean by preventing carbon and varnish buildup during normal operation.

Don't Run on a Low Fuel Tank: Consistently driving with a near-empty tank can stir up sediment and debris settled at the bottom of the fuel tank, which can be pulled into the fuel pump and pushed toward the injector filters.

Drive the Vehicle Regularly: Extended periods of inactivity allow fuel to evaporate in the injector tips, leaving behind gummy deposits that can clog the fine holes.

Proactive Maintenance Schedule:

Every 30,000 - 45,000 miles (50,000 - 70,000 km):

Every 60,000 - 90,000 miles (or if symptoms appear):

Professional Cleaning: If you experience symptoms of a clogged injector—such as rough idle, engine misfires, hesitation, or reduced fuel economy—have them professionally cleaned. This involves removing the injectors and using an ultrasonic cleaner and a bench-top machine that pulses solvent through them while measuring their flow rate. This is the most effective cleaning method.

At Time of Replacement (or major service):

Replace Seals: Whenever injectors are removed, ALWAYS replace the insulator seals and O-rings (Denso kit 9001-10001 is common for this application). These seals harden and shrink over time due to heat and will cause vacuum and fuel leaks if reused.

Rsolid is a professional diesel system parts manufacturer that provides high-quality and durable diesel pump and injector replacement parts for different brands of engines. If you are looking for diesel engine parts, please feel free to contact us at any time.