Address the Root Cause: A failing injector can sometimes be a symptom of another problem, such as contaminated fuel, a failing high-pressure oil pump, or a weak ECM driver. A good technician will diagnose the entire system.

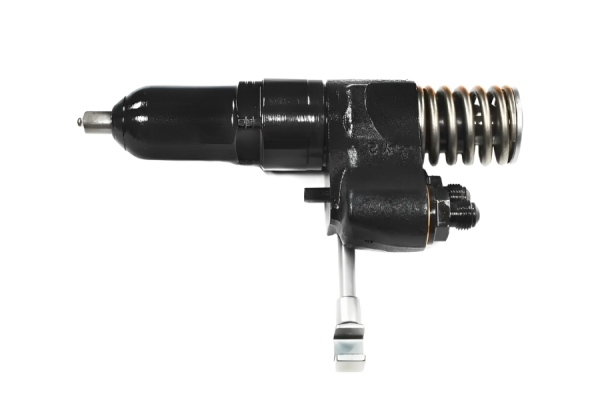

The Caterpillar 128-6601 HEUI fuel injector has several distinct advantages and features that stem from its innovative design, which differs significantly from traditional mechanical or common-rail injectors.

Here’s a breakdown of its key advantages and features:

Key Features (The "What it Is")

HEUI Technology (Hydraulically-Actuated, Electronically-Controlled Unit Injector):

Dual-Fluid System: This is the core feature. It uses engine oil (hydraulic fluid) for actuation pressure and diesel fuel for injection.

Electronically Controlled Solenoid: A solenoid valve, controlled by the engine's ECM (Electronic Control Module), opens and closes to precisely start and stop fuel injection.

Pressure Multiplication: The injector contains an intensifier piston. High-pressure engine oil acts on the large area of this piston, which in turn acts on a smaller-area piston pressurizing the fuel. This mechanically multiplies the oil pressure, creating extremely high fuel injection pressures (often over 30,000 psi / 2,000 bar) without the need for a camshaft or a ultra-high-pressure fuel pump.

Integrated Unit Injector Design: It combines the injection pump and injector nozzle into a single unit that sits directly in the cylinder head. This eliminates high-pressure fuel lines, reducing potential leak points and pressure losses.

Advantages (The "Why it Matters")

The features above translate into direct benefits for engine performance, efficiency, and control.

High Injection Pressure Independent of Engine Speed:

Cleaner Combustion: Less soot and particulate matter.

Better Cold Starts: Excellent atomization even when cranking.

More Power and Torque: Efficient burning at low RPMs.

Feature: Uses pressurized engine oil from a separate pump, not the camshaft.

Advantage: Unlike traditional systems where injection pressure drops at low RPM, the HEUI system can maintain optimal, high injection pressure at any engine speed. This results in superior fuel atomization across the entire operating range, leading to:

Unmatched Injection Control and Flexibility:

Pilot Injection: A tiny amount of fuel is injected before the main injection event to soften combustion, drastically reducing noise (knock) and NOx emissions.

Rate Shaping: Controlling the shape of the injection rate for a smoother and more efficient burn.

Multiple Injection Events: Precisely timed bursts of fuel for optimal power and minimum emissions.

Feature: Full electronic control via the ECM.

Advantage: The ECM can manage injection timing and duration with extreme precision. This allows for advanced strategies like:

Excellent Reliability and Packaging:

Eliminates Line Failures: No risk of catastrophic high-pressure fuel line ruptures.

Compact Design: Simplifies the engine design by integrating functions into one component.

Consistent Performance: With fewer external components, performance is more consistent and reliable.

Feature: Unit injector design with no high-pressure lines.