The Denso 095000-6410 fuel injector, while a seemingly simple component, incorporates several key technical advantages that contribute to engine performance, efficiency, and reliability. These advantages are a result of Denso's expertise in precision manufacturing and materials science.

Here are the primary technical advantages of this specific injector:

1. Exceptional Precision and Flow Matching

Tight Manufacturing Tolerances: Denso manufactures these injectors to extremely precise specifications. This ensures minimal variation in flow rates from one injector to another.

Inherently Matched Sets: Because of this precision, a set of new 095000-6410 injectors is essentially "flow-matched" from the factory. This is critical for engine balance; all cylinders receive the same amount of fuel for a given injector pulse width from the ECU, leading to smooth operation, optimal power, and minimal emissions.

2. Superior Atomization

Disc-Type Multi-Hole Design: Unlike older pintle-style or single-hole injectors, the 095000-6410 typically uses a multi-hole disc at its tip.

Advantage: This design breaks the fuel into a finer, more consistent spray pattern (a mist rather than a stream). Better atomization allows the fuel to vaporize more completely and mix evenly with the air in the intake manifold. This results in:

3. High-Impedance Design

4. Rapid Response Time

Fast Opening and Closing: The injector's solenoid and internal spring are engineered for very quick reaction times. It opens and closes rapidly in response to the ECU's signal.

Advantage: This fast response allows for extremely precise fuel metering, especially at low pulse widths (idle, low load). This precision is essential for modern engines to meet strict fuel economy and emissions standards without sacrificing drivability.

5. Robust and Durable Materials

Here is a detailed breakdown of what it is, what vehicles it fits, and important information about it.

1. What is this Injector?

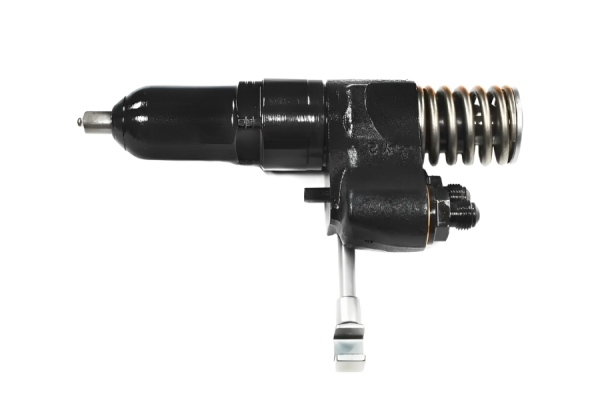

The Denso 095000-6410 is a saturated-type, high-impedance fuel injector. This is a standard solenoid-operated injector used in Port Fuel Injection (PFI or MPI) systems, where it is mounted in the intake manifold, spraying fuel just upstream of the intake valve.

Saturated-Type: This refers to the electrical driver circuit used by the vehicle's ECU. It's a simpler, slower-acting circuit compared to "peak and hold" injectors (which are low-impedance). This is the most common type for many modern vehicles.

High-Impedance: It has a high electrical resistance (typically 12-16 Ohms). This means it draws less current and can be driven directly by the ECU without needing a separate resistor pack, which low-impedance injectors often require.

2. Key Specifications

Flow Rate: Approximately ~310 cc/min @ 3 Bar (43.5 PSI). (Always confirm the exact flow rate for your specific application, as it can vary slightly).

Connector Type: USCAR (a common modern standard) or a similar oval-shaped electrical connector.

Seal Type: It uses both upper and lower O-rings for sealing, and often a small plastic insulator or spacer at the top.

3. Common Vehicle Applications

This is a very popular injector and is used as original equipment (OE) on many Toyota, Lexus, and Scion models from the mid-2000s to the early 2010s. Always cross-reference your VIN number with a reliable parts catalog before purchasing, but common fits include:

Toyota:

Lexus:

Scion:

(Note: This is not an exhaustive list. It was used on various models with the 2GR-FE 3.5L V6 and 2AZ-FE 2.4L engines, among others).

4. Why is this Number Important? (Cleaning & Flow Testing Kits)

You will often see this part number 095000-6410 used to identify complete sets of refurbished injectors or, more commonly, universal fuel injector cleaning/flow test kits for hobbyists and small shops.

The injector's specific dimensions and electrical properties make it a perfect candidate to be used as a standardized "test body" in these kits. The kit includes adapters that allow you to connect a bank of injectors from almost any vehicle to a bench cleaning system, using the Denso 6410's connector and port as the universal interface.

5. Important Considerations Before You Buy/Use

New vs. Remanufactured vs. Used: You can find this injector as a new OEM part, a remanufactured part (cleaned, tested, and with new seals), or used. Remanufactured from a reputable seller is a very common and cost-effective choice.

Must Replace Seals: If you are reinstalling injectors, you MUST use a new seal kit. The old O-rings become hard, brittle, and will likely leak, causing a dangerous fire hazard. A seal kit is inexpensive and crucial.

Matched Sets: For best engine performance, it's ideal to have a "matched set" of injectors where the flow rates have been tested and are within a very close percentage of each other (e.g., within 1-2%). Reputable rebuilders provide flow-matched sets.

Cross-Reference: This is the most important step. While 095000-6410 is a common fit, always double-check compatibility for your specific Year, Make, Model, and Engine Size.