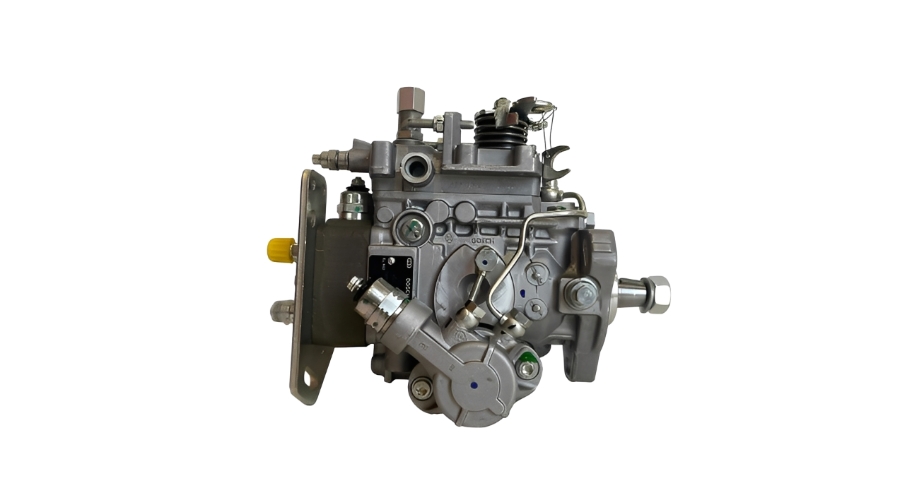

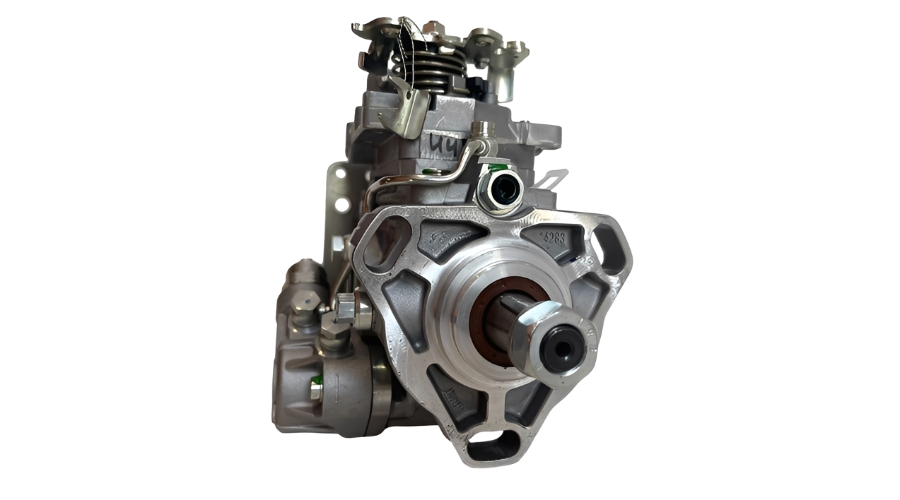

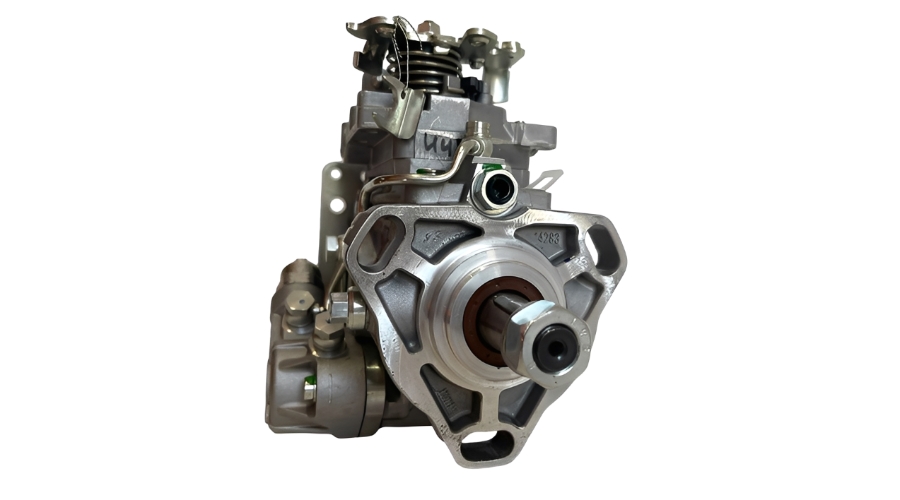

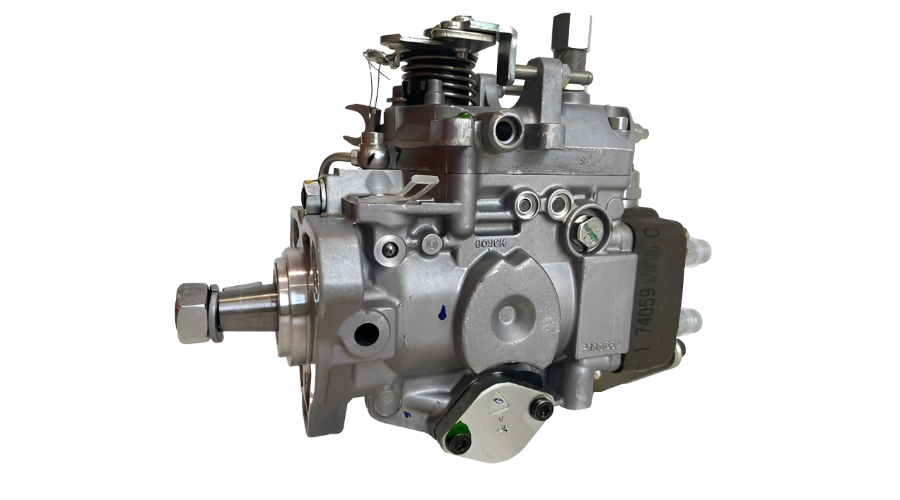

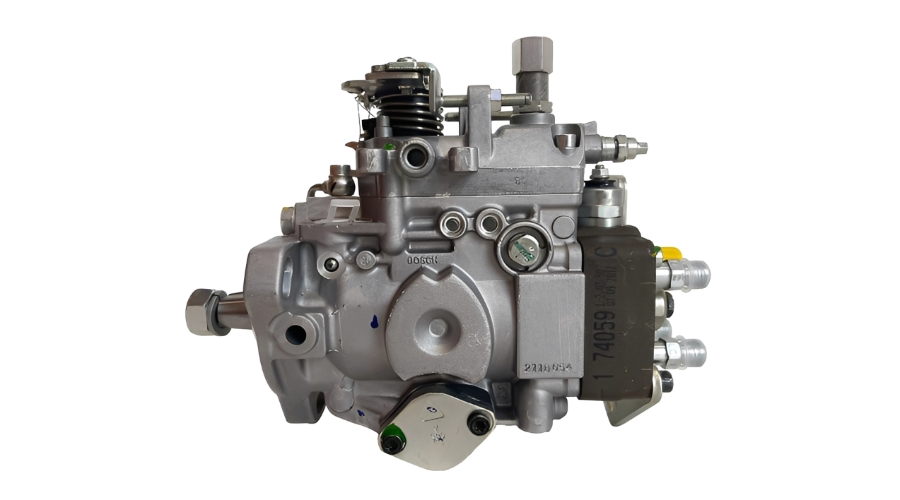

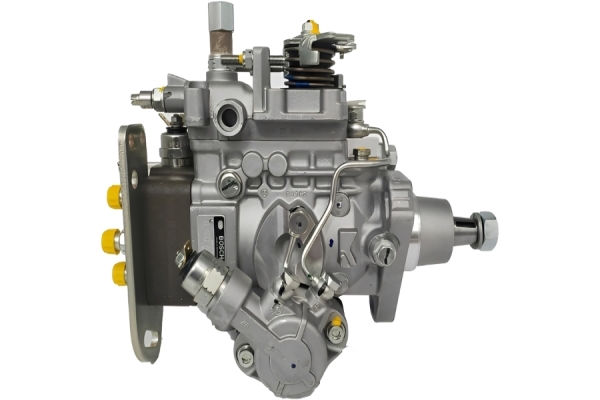

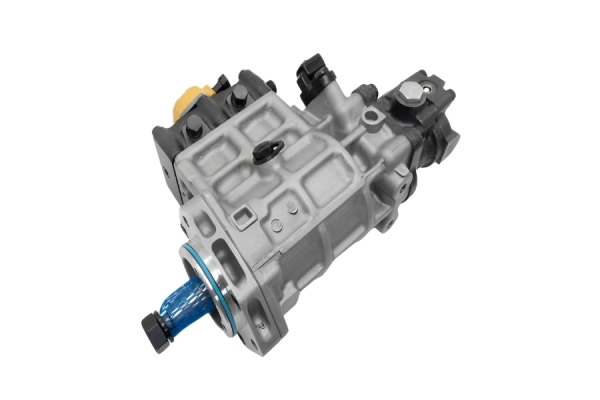

The Bosch 0460424315 diesel fuel injection pump is likely a rotary-type (VE) distributor pump, commonly used in small to medium-duty diesel engines. Below is a brief overview of its structural characteristics, advantages, and applications:

1. Structural Characteristics

Type: Rotary distributor pump (Bosch VE series)

Fuel Delivery: Uses a single plunger to distribute fuel to each cylinder in sequence.

Governor Mechanism: Mechanical or hydraulic governor for RPM control.

High-Pressure Generation: Cam-driven plunger creates the necessary injection pressure.

Integrated Components:

Vane-type feed pump (for fuel supply)

Advance mechanism (for timing adjustment)

Solenoid shutoff valve (for engine stop)

2. Main Advantages

✔ Compact & Lightweight – Suitable for small and mid-sized engines.

✔ Precise Fuel Metering – Ensures efficient combustion and lower emissions.

✔ Reliable & Durable – Robust construction for long service life.

✔ Self-Lubricating Design – Uses diesel fuel for internal lubrication.

✔ Easy Maintenance – Fewer moving parts compared to inline pumps.

3. Application Scenarios & Equipment

This pump is typically found in:

Automotive Engines: Small trucks, vans, and passenger diesel cars.

Agricultural Machinery: Tractors, harvesters, and irrigation pumps.

Industrial Engines: Generators, construction equipment, and marine auxiliaries.

Popular Engine Brands:

Deutz, Perkins, Mitsubishi, Isuzu, Kubota (varies by exact model).

4. Common Replacement & Servicing Notes

Rebuild Kits Available: Seals, plungers, and governor parts can be replaced.

Critical for Performance: Proper calibration ensures fuel efficiency and power.

Counterfeit Risk: Buy from authorized Bosch dealers to avoid fake parts.

Common Problems with Bosch 0460424315 Diesel Injection Pump (VE Type)

The Bosch VE rotary distributor pump is generally reliable, but over time, the following issues may occur:

1. Hard Starting or Failure to Start

Causes:

Worn plunger or distributor head

Faulty solenoid shutoff valve

Air ingress in the fuel system

Weak feed pump pressure

2. Uneven Engine Performance or Misfiring

Causes:

Sticky or worn delivery valves

Incorrect injection timing

Dirty fuel clogging the distributor

3. Excessive Smoke (Black/White)

4. Loss of Power or Poor Acceleration

5. Fuel Leaks

6. Unstable Idling or Surging RPM

Daily & Preventive Maintenance Tips

1. Use Clean, High-Quality Diesel

2. Change Fuel Filters on Schedule

Replace filters per manufacturer recommendations (typically every 10,000–15,000 km or 200–500 engine hours).

Bleed air from the system after filter changes.

3. Check for Fuel Leaks

Inspect pump seals, fuel lines, and connections for leaks.

Replace worn O-rings and seals promptly.

4. Monitor Engine Performance

5. Maintain Proper Fuel Tank Hygiene

6. Avoid Prolonged Low-RPM Operation

7. Periodic Professional Servicing

Have the pump tested and recalibrated every 50,000–100,000 km (or as per engine manual).

Replace worn internals (plunger, cam plate, governor) before catastrophic failure.

Diesel Fuel pump Supplier:

Rsolid is a professional diesel fuel pump manufacturer provides high quality and durable diesel fuel pump replaements for different brands of engines or produce fuel pump according to your request. If you are looking for diesel pump or OEM engine parts, feel free to contact us.