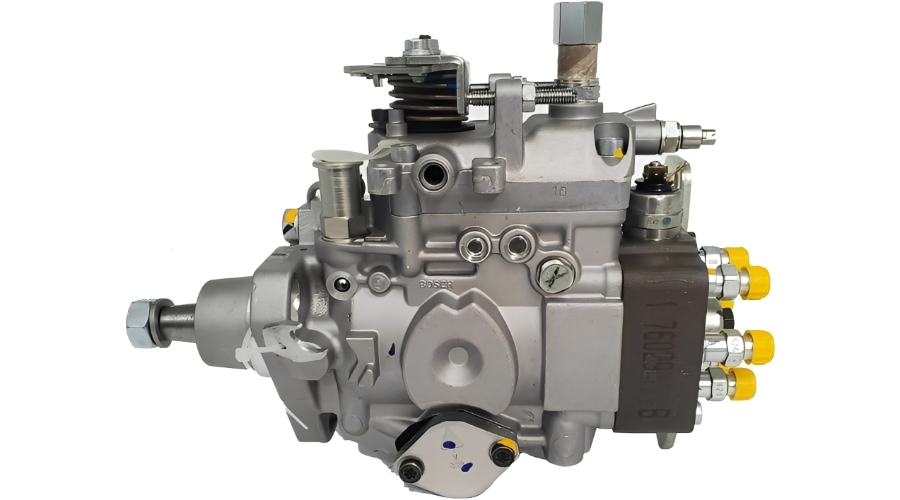

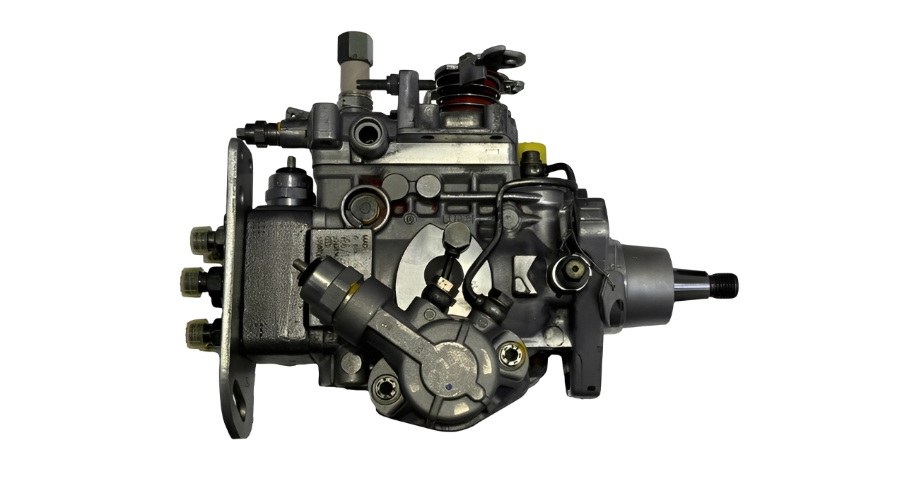

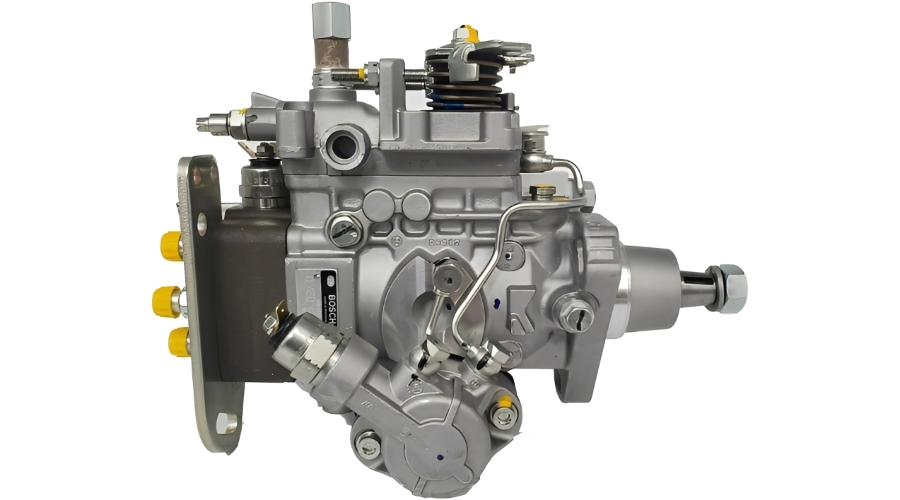

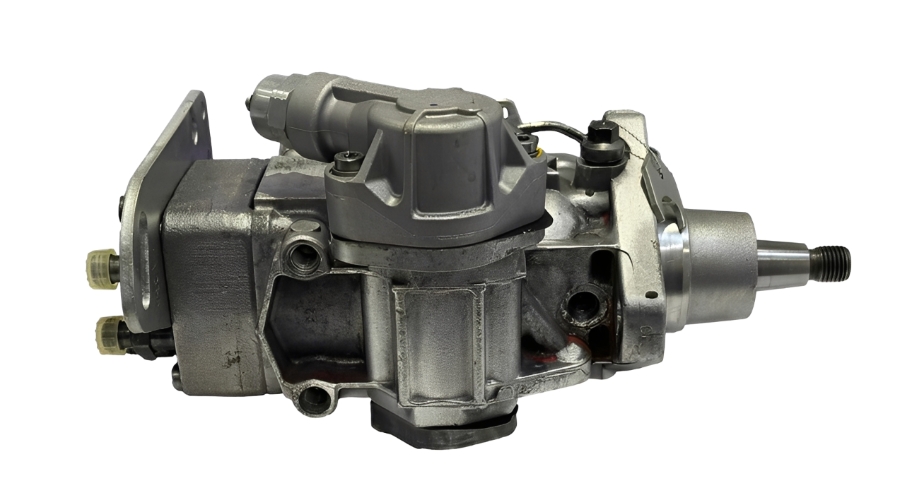

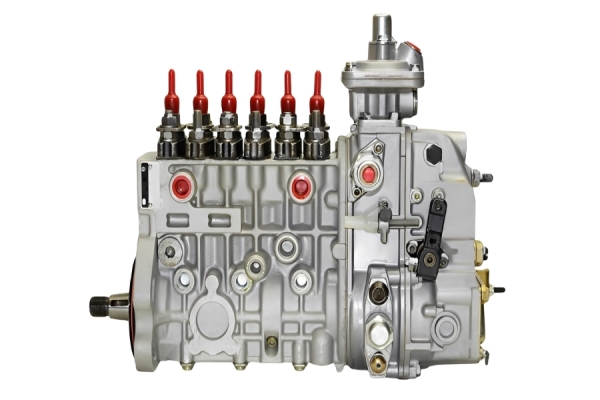

The Bosch Fuel Injection Pump (0460426357 / VEL936) is a high-precision mechanical fuel delivery system designed for diesel engines, particularly in New Holland tractors and other agricultural/industrial machinery. Below are its structural features, advantages, and application scenarios:

1. Structural Features

a) Rotary Distributor Design

Uses a single plunger and distributor rotor to deliver fuel sequentially to each cylinder, ensuring balanced fuel distribution.

Compact and lightweight compared to inline pumps.

b) Mechanical Governor System

c) High-Pressure Fuel Delivery

Generates injection pressures up to 1,000 bar (depending on calibration), ensuring efficient atomization for cleaner combustion.

Precision-machined plunger and barrel assembly minimizes leakage and wear.

d) Built-In Fuel Supply Pump

e) Hydraulic Timing Advance Mechanism

f) Robust Construction

Made from high-strength alloys to withstand harsh agricultural conditions.

Sealed housing to prevent dirt, water, and debris ingress.

2. Advantages

✔ Fuel Efficiency – Precise metering reduces diesel consumption.

✔ Reliability – Bosch’s engineering ensures long service life even under heavy loads.

✔ Smooth Engine Operation – Balanced fuel distribution minimizes vibrations.

✔ Lower Emissions – Better combustion reduces smoke and particulate emissions.

✔ Easy Maintenance – Fewer moving parts than inline pumps, simplifying service.

3. Application Scenarios

This pump is commonly used in:

a) New Holland Tractors

Models such as TL, TS, T4, T5, TM, or TN series (verify exact compatibility).

Suitable for medium to high horsepower diesel engines (e.g., 4-6 cylinder engines).

b) Agricultural Machinery

c) Industrial & Construction Equipment

d) Retrofit & Replacement Market

Conclusion:

The Bosch 0460426357 (VEL936) fuel injection pump is a durable, efficient, and precision-engineered component ideal for agricultural and industrial diesel engines. Its rotary distributor design, self-contained feed pump, and hydraulic timing advance make it a reliable choice for New Holland tractors and similar machinery.

Proper preventive maintenance of the Bosch 0460426357 (VEL936) fuel injection pump is crucial for ensuring longevity, fuel efficiency, and reliable engine performance in your New Holland tractor or other diesel machinery. Here are some key maintenance recommendations:

1. Regular Fuel System Checks

✅ Use Clean, High-Quality Diesel

Always use filtered, low-sulfur diesel to prevent contamination.

Avoid stale or water-contaminated fuel (common in long storage).

✅ Replace Fuel Filters Regularly

Change primary and secondary fuel filters per the manufacturer’s schedule (typically every 200-500 hours).

Clogged filters strain the injection pump, leading to premature wear.

✅ Drain Water from the Fuel System

2. Lubrication & Seal Maintenance

✅ Check Engine Oil Levels

✅ Inspect for Fuel Leaks

Look for wet spots or diesel odors around the pump.

Worn seals or O-rings can cause leaks, leading to air ingress and poor performance.

✅ Use Diesel Additives (If Needed)

3. Air Intake & Ventilation

✅ Keep the Air Filter Clean

A clogged air filter causes uneven combustion, increasing pump workload.

Replace or clean filters as recommended.

✅ Ensure Proper Fuel Tank Venting

4. Operational Best Practices

✅ Avoid Running on Empty Fuel Tank

✅ Warm Up the Engine in Cold Weather

✅ Do Not Over-Rev the Engine

5. Periodic Professional Inspection

✅ Check Injection Timing

Misalignment causes hard starting, power loss, or excessive smoke.

Requires specialized tools – best done by a diesel technician.

✅ Monitor Pump Performance

If you notice uneven idle, power loss, or black/white smoke, get the pump inspected.

Early detection prevents costly repairs.

✅ Consider Rebuilding After Long Use

6. Storage & Long-Term Care

✅ If Storing the Tractor Long-Term

Diesel Fuel pump Supplier:

Rsolid is a professional diesel fuel pump manufacturer provides high quality and durable diesel fuel pump replaements for different brands of engines or produce fuel pump according to your request. If you are looking for diesel pump or OEM engine parts, feel free to contact us.