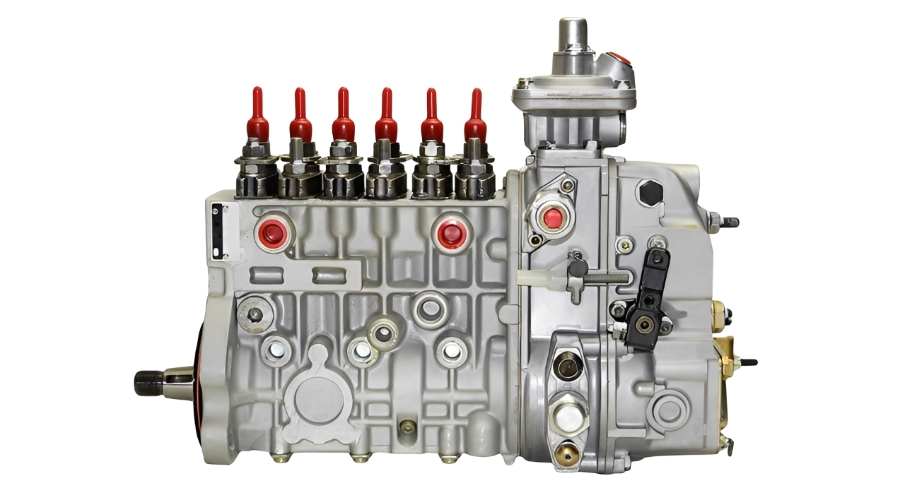

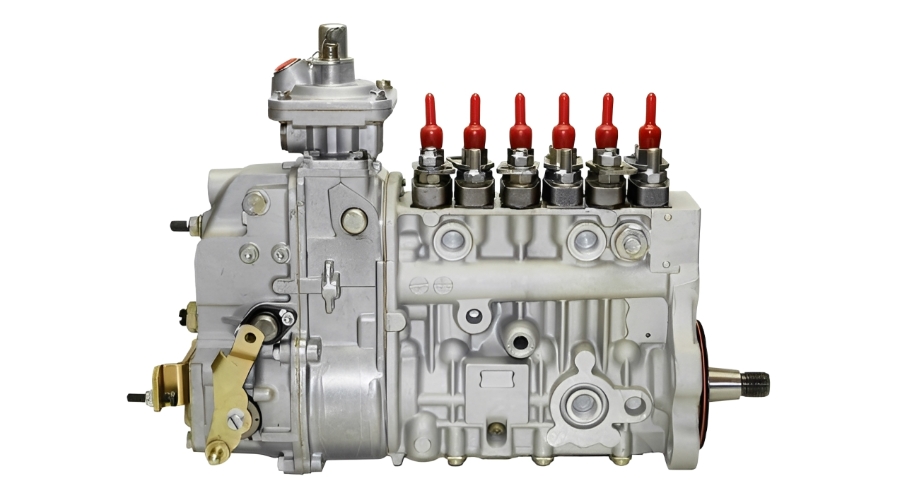

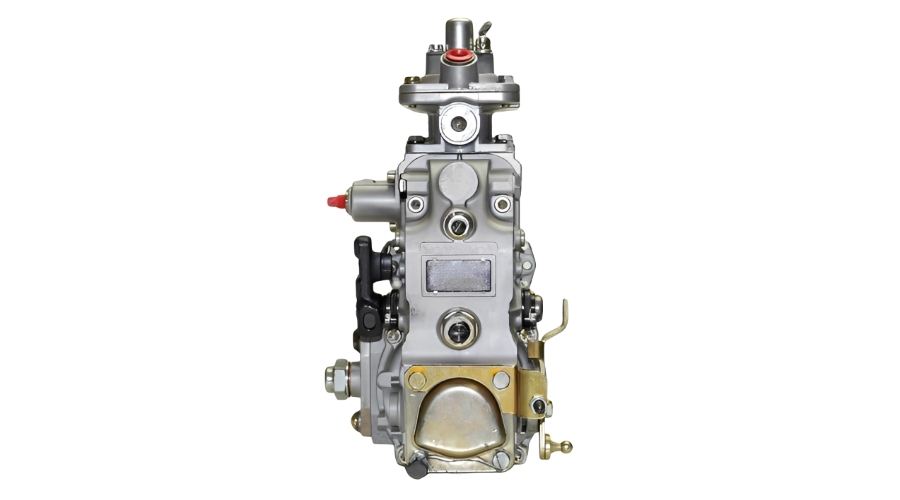

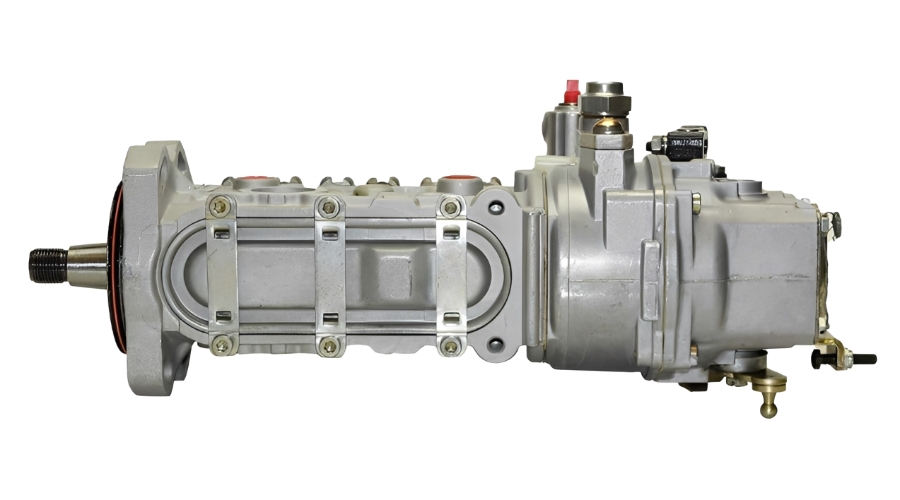

Cummins 6CTA Fuel Pump (Part #3926881) – Detailed Analysis

The Cummins 6CTA 8.3L engine uses a mechanical fuel pump (part #3926881) designed for reliable fuel delivery in demanding conditions. Below is a detailed breakdown of its structural characteristics, advantages, applications, common failures, and maintenance procedures.

1. Structural Characteristics

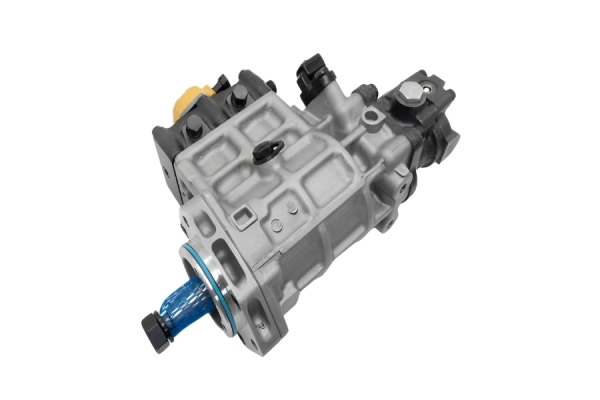

The 3926881 fuel pump is a mechanical lift pump, typically mounted on the engine block and driven by a camshaft lobe. Its key structural features include:

A. Key Components

Housing & Body

Diaphragm Mechanism

Inlet & Outlet Ports

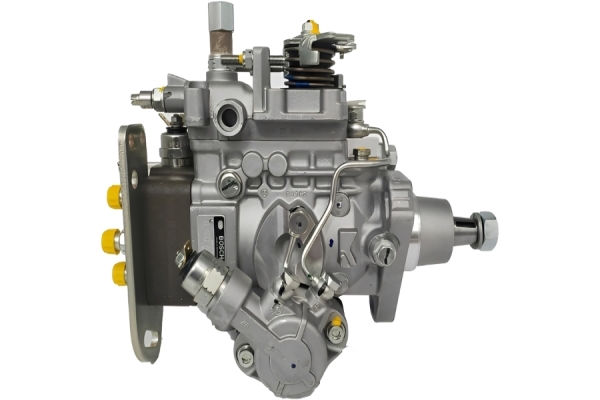

Inlet: Connects to the fuel tank via a supply line.

Outlet: Delivers fuel to the injection pump (e.g., Bosch VP44 or rotary pump).

Manual Primer Lever

Check Valves

2. Advantages of the 3926881 Fuel Pump

✔ Reliable & Simple Design – Fewer electronic components mean fewer failure points.

✔ Self-Priming Capability – Works efficiently even after fuel system drainage.

✔ Durable Construction – Resists wear from diesel contaminants.

✔ Cost-Effective – Cheaper than electric pumps and easier to replace.

✔ Compatible with Mechanical Injection Systems – Works well with older Cummins engines without electronic controls.

3. Main Application Scenarios & Equipment

This pump is commonly found in:

A. Industrial & Construction Equipment

Generators (e.g., Cummins-powered standby generators)

Excavators, Loaders, and Bulldozers

Mining Equipment

B. Marine Applications

C. Heavy-Duty Trucks & Buses

Military Vehicles (e.g., M939 series trucks)

Older Freightliner, International, and Peterbilt Trucks

4. Common Problems & Failures

Despite its reliability, the 3926881 fuel pump can experience issues:

A. Common Failures

Loss of Fuel Pressure

Causes: Worn diaphragm, stuck check valve, or leaking seals.

Symptoms: Hard starting, engine stalling, power loss.

Fuel Leaks

Causes: Cracked housing, damaged gasket, or loose fittings.

Symptoms: Diesel odor, visible wetness around the pump.

No Fuel Delivery

Causes: Broken pushrod, seized diaphragm, or clogged inlet.

Symptoms: Engine cranks but won’t start.

Excessive Noise (Clicking or Knocking)

5. How to Check & Maintain the Fuel Pump

A. Inspection & Testing

Visual Check

Manual Priming Test

Pressure Test

Flow Test

B. Maintenance Tips

✔ Replace Fuel Filters Regularly – Prevents debris from damaging the pump.

✔ Check Pushrod Wear – If the pump is removed, inspect the camshaft pushrod.

✔ Use Clean Diesel Fuel – Contaminants accelerate wear.

✔ Inspect for Air Leaks – Air entering the system reduces efficiency.

Conclusion:

The Cummins 3926881 fuel pump is a robust, mechanical lift pump ideal for industrial, marine, and heavy-duty applications. While durable, it can fail due to diaphragm wear, leaks, or pressure loss. Regular inspection, pressure testing, and proper fuel filtration will extend its lifespan.

Diesel pump Supplier:

Rsolid is a professional diesel fuel pump manufacturer provides high quality and durable diesel fuel pump replaements for different brands of engines or produce fuel pump according to your request. If you are looking for diesel pump or OEM engine parts, feel free to contact us.