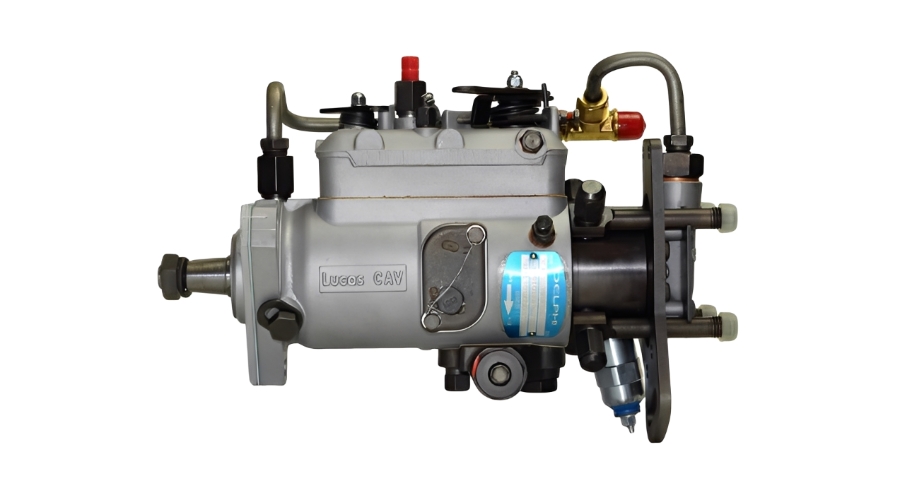

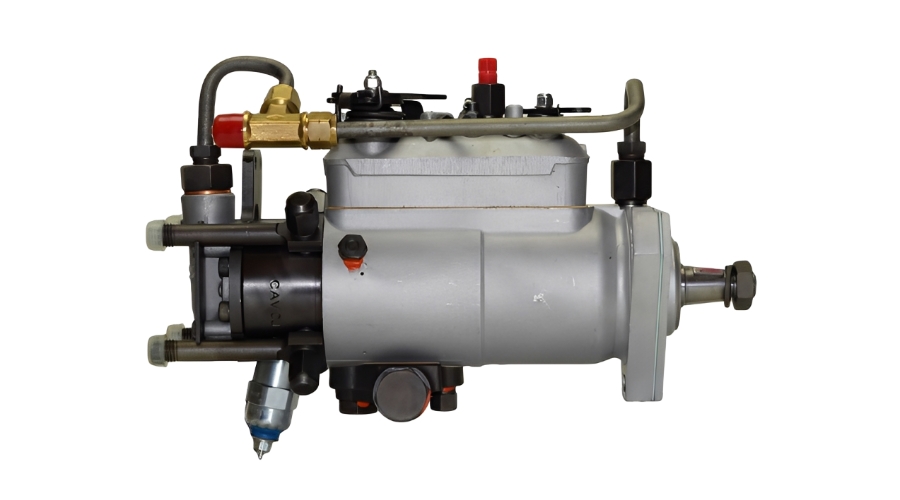

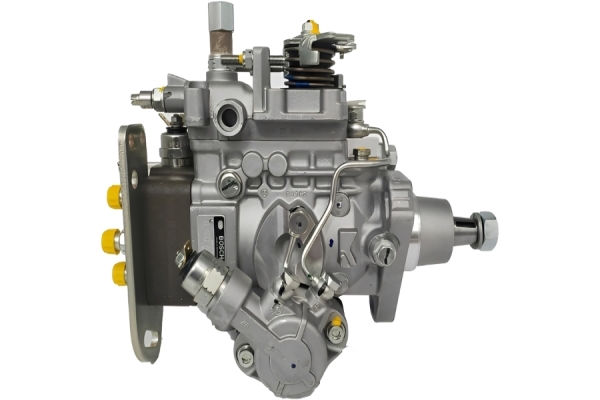

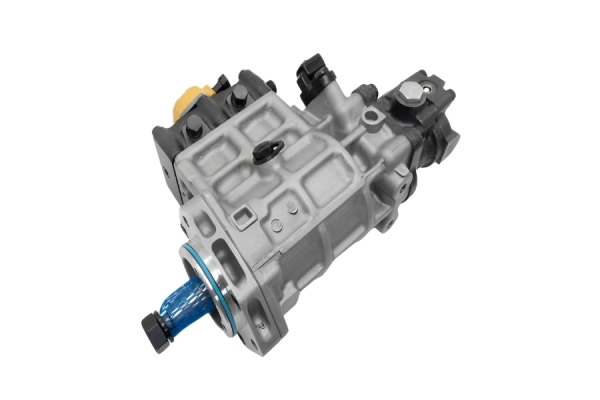

Detailed Description of the Cummins 4BT Fuel Pump (3042F330) – Structural Features & Advantages

1. Structural Features:

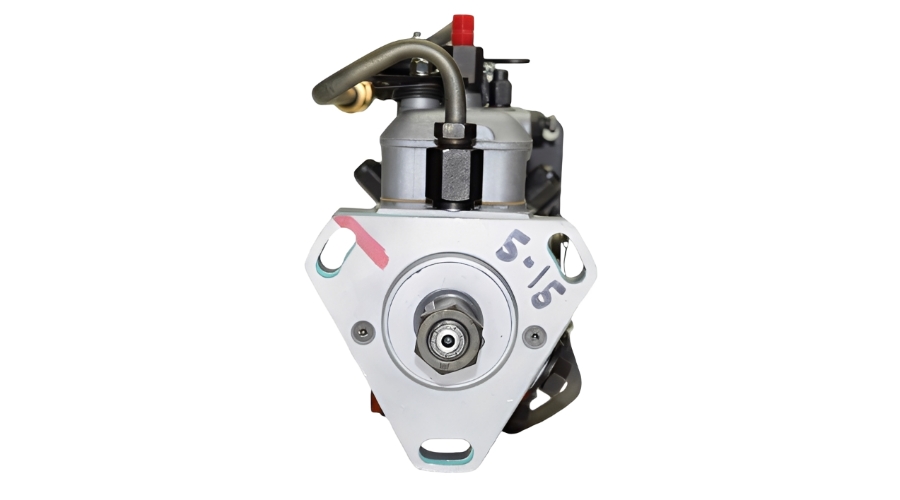

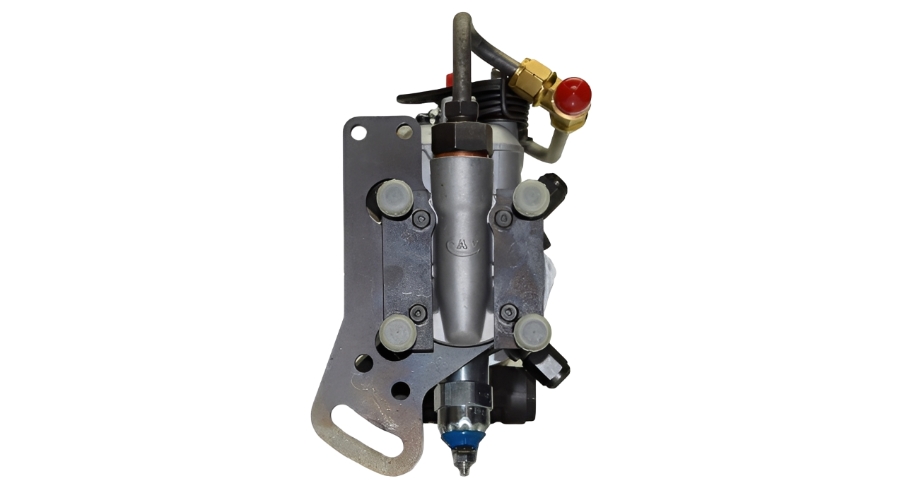

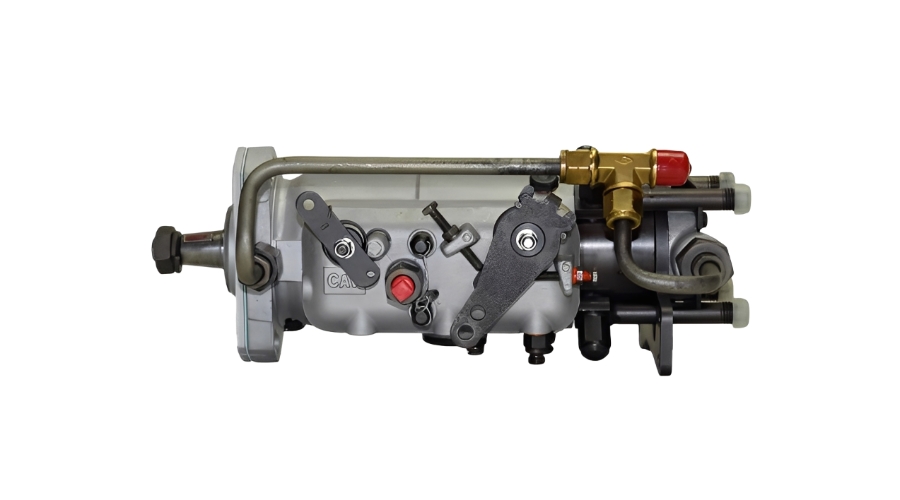

The 3042F330 is a mechanical fuel supply pump designed for the Cummins 4BT engine. Its key structural components include:

Pump Body: Made of durable cast aluminum or steel to withstand high-pressure diesel fuel and engine vibrations.

Diaphragm Mechanism: Uses a rubber or synthetic diaphragm to create suction and pressure for fuel delivery.

Inlet & Outlet Ports: Standard threaded fittings (typically ¼" or ⅜") for fuel line connections.

Lever-Actuated Design: Operated by an eccentric cam on the engine, which moves a lever to pump fuel.

Check Valves: Prevents fuel backflow, ensuring consistent pressure to the injection pump.

Mounting Flange: Bolt-on design for secure attachment to the engine block or timing gear housing.

2. Advantages:

✔ Reliable Mechanical Operation – No electrical components, reducing failure risk.

✔ Consistent Fuel Delivery – Maintains steady pressure for optimal combustion.

✔ Durability – Built to withstand harsh conditions (agricultural, construction, marine).

✔ Easy Maintenance – Simple design allows for straightforward replacement.

✔ Compatibility – Direct fit for Cummins 4BT engines with minimal modifications.

Main Application Scenarios & Equipment Models

The 3042F330 fuel pump is primarily used in industrial, agricultural, and automotive diesel engines, including:

1. Industrial & Construction Equipment:

Generators (e.g., Cummins-powered standby generators)

Compressors & Pumps (diesel-driven units)

Skid Steer Loaders (e.g., Bobcat 773, 863 with Cummins conversions)

2. Agricultural Machinery:

Tractors (e.g., Case IH, older Ford tractors with 4BT swaps)

Combine Harvesters & Balers (retrofitted diesel applications)

3. Automotive & Truck Applications:

Medium-Duty Trucks (e.g., Freightliner FL60, International S1700 with 4BT swaps)

Military Vehicles (e.g., Humvee HMMWV with Cummins conversions)

RV & Bus Conversions (4BT engines used in motorhomes)

4. Marine Applications:

Conclusion:

The 3042F330 fuel pump is a robust, mechanically driven component essential for reliable fuel delivery in Cummins 4BT engines. Its durability and simple design make it ideal for heavy-duty applications in construction, agriculture, trucks, and marine use.

The 3042F330 mechanical fuel pump is generally reliable, but like any component, it can develop issues over time. Below are the most common problems and maintenance recommendations to ensure longevity and optimal performance.

🔧 Common Problems with the 3042F330 Fuel Pump

1. Fuel Leaks

Symptoms:

Diesel odor around the engine

Visible wetness near the pump

Fuel dripping from the diaphragm or gasket area

Causes:

Worn-out diaphragm (common in older pumps)

Cracked pump housing due to engine vibrations

Degraded gasket or O-ring seals

2. Loss of Fuel Pressure (Weak or No Fuel Delivery)

Symptoms:

Causes:

Worn internal check valves

Sticking diaphragm or lever mechanism

Clogged fuel inlet screen (if equipped)

3. Pump Failure (No Fuel Flow)

4. Excessive Noise (Clicking or Knocking Sounds)

🛠️ Maintenance & Troubleshooting Suggestions

✅ Regular Inspection & Preventive Maintenance

Check for Leaks – Inspect the pump body, gasket, and fuel lines monthly.

Monitor Fuel Pressure – Use a gauge to ensure proper pressure (typically 4-7 PSI for mechanical pumps).

Replace Fuel Filters – Clogged filters force the pump to work harder, accelerating wear.

Inspect the Diaphragm – If the pump has been in service for 50,000+ miles, consider a rebuild or replacement.

🔄 Troubleshooting Steps if Problems Occur

| Issue | Diagnosis | Solution |

|---|

| Fuel Leak | Check gasket & diaphragm | Replace gasket or entire pump |

| Low Pressure | Test with a fuel pressure gauge | Clean/replace inlet screen, check valves |

| No Fuel Flow | Disconnect outlet hose & crank engine | Replace pump if no fuel comes out |

| Excessive Noise | Listen for irregular ticking | Check lever arm wear, tighten bolts |

⚡ Upgrades & Replacement Options

OEM Replacement: Stick with Cummins 3042F330 for factory reliability.

Aftermarket Pumps: Brands like Rsolid offer cost-effective alternatives.

🔧 When to Replace the Fuel Pump?

If fuel leaks cannot be fixed with a new gasket.

If the engine loses power and diagnostics confirm weak fuel delivery.

If the pump is original and has over 100,000 miles.