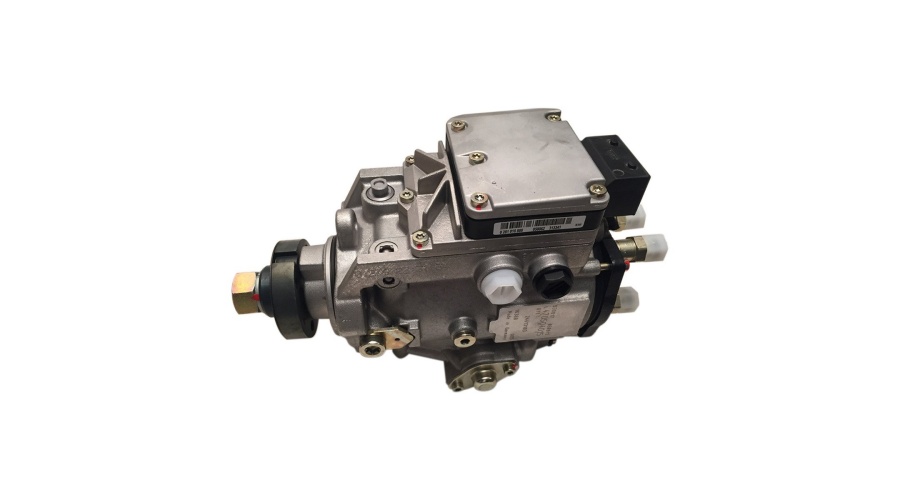

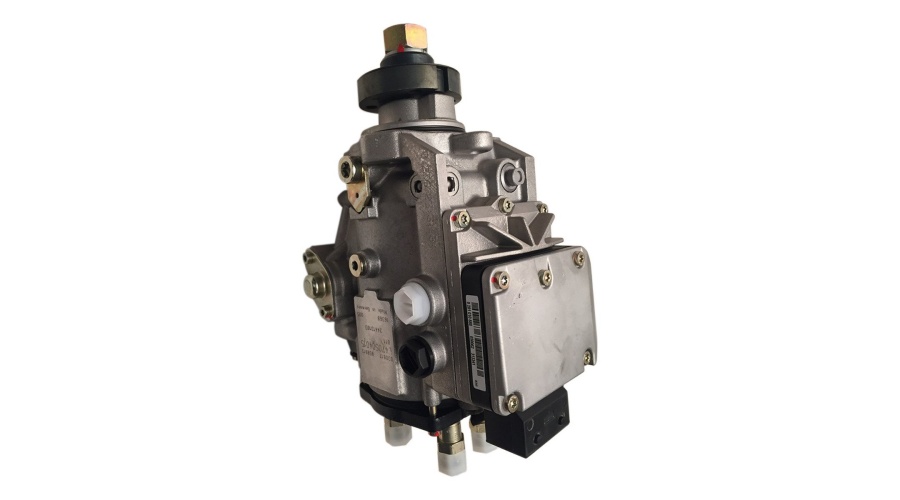

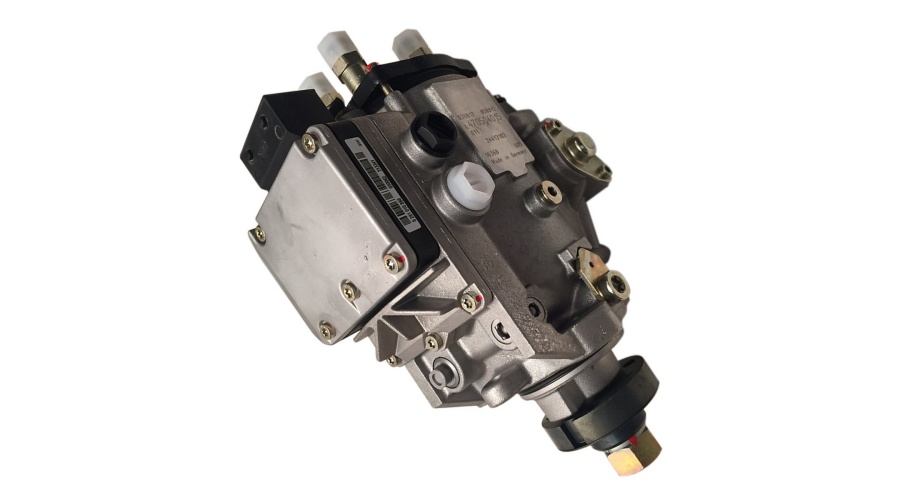

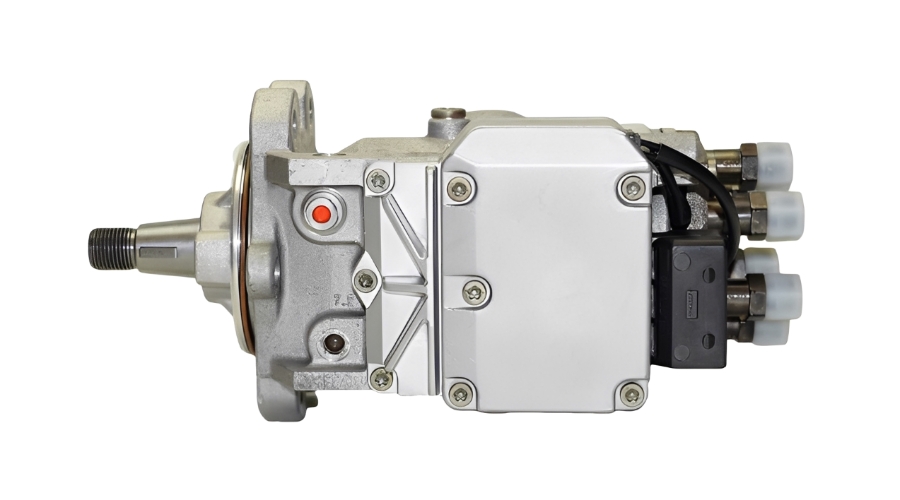

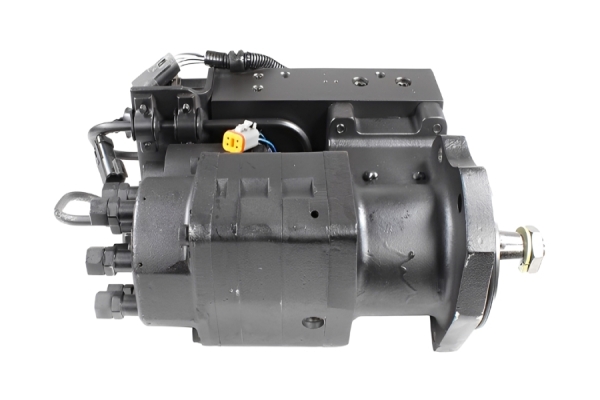

The Cummins 3944535 fuel injection pump is a critical component in diesel engines, ensuring precise fuel delivery for optimal combustion. Below is a detailed breakdown of its structural characteristics, advantages, application scenarios, and compatible equipment models.

1. Structural Characteristics

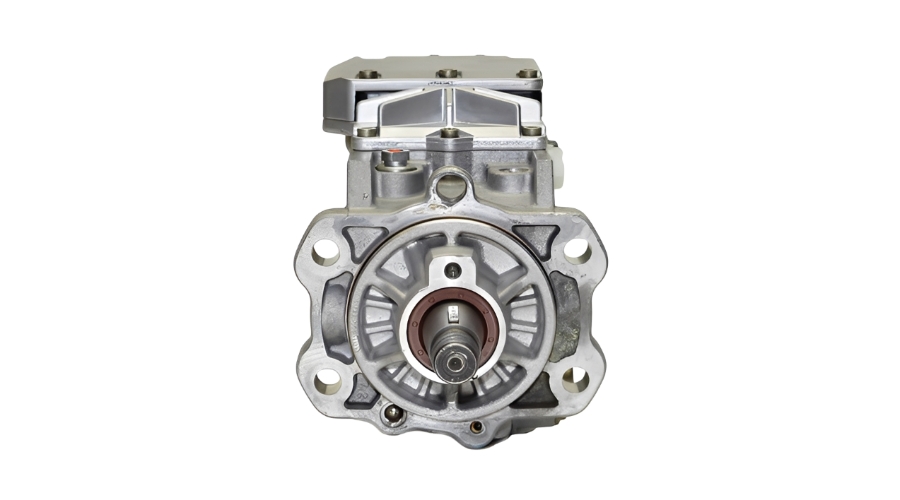

The 3944535 fuel injection pump is a mechanical rotary distributor-type pump, commonly used in Cummins diesel engines. Key structural features include:

A. Pump Design & Components

Rotary Distributor Mechanism – Ensures even fuel distribution to each cylinder.

High-Pressure Plunger – Generates the necessary pressure (typically 1,800–3,000 psi) for efficient atomization.

Governor Assembly – Regulates engine speed by controlling fuel delivery.

Advance Mechanism – Adjusts injection timing based on RPM for optimal performance.

Integrated Fuel Transfer Pump – Some models include a built-in lift pump to supply fuel from the tank.

B. Material & Durability

Hardened Steel Components – Resistant to wear from high-pressure operation.

Precision Machined Parts – Ensures tight tolerances for consistent fuel delivery.

Corrosion-Resistant Seals – Prevents diesel leaks and extends service life.

2. Advantages of the 3944535 Fuel Injection Pump

✔ Precision Fuel Delivery – Ensures optimal air-fuel mixture for efficiency and power.

✔ Durability – Designed for long service life in harsh conditions.

✔ Consistent Performance – Maintains stable injection pressure across RPM ranges.

✔ Lower Emissions – Helps meet EPA/CARB standards by improving combustion.

✔ Easy Maintenance – Some models allow in-place servicing without full removal.

3. Application Scenarios & Compatible Equipment

This pump is used in a variety of industrial, automotive, and heavy machinery applications, including:

A. Common Cummins Engine Models

B Series Engines → 4BT (3.9L), 6BT (5.9L)

C Series Engines → 8.3L C8.3

ISB & QSB Engines → ISB5.9, QSB6.7

ISC & QSC Engines → ISC8.3, QSC8.3

B. Typical Equipment & Machines Using This Pump

Construction Equipment → Excavators, bulldozers, loaders

Agricultural Machinery → Tractors, combines, harvesters

Trucks & Buses → Medium-duty trucks, school buses

Marine & Generator Sets → Auxiliary power units (APUs), marine propulsion

Industrial Power Units → Pumps, compressors, mining equipment

4. Maintenance & Troubleshooting Tips

Regular Fuel Filter Changes – Prevents contaminants from damaging the pump.

Use High-Quality Diesel – Poor fuel can cause wear and clogging.

Check for Leaks – Worn seals may lead to pressure loss.

Monitor Injection Timing – Improper timing reduces efficiency.

Conclusion:

The Cummins 3944535 fuel injection pump is a robust, high-performance component designed for precision fuel delivery in demanding environments. Its durability, efficiency, and compatibility with various Cummins engines make it a reliable choice for trucks, construction equipment, agricultural machinery, and industrial applications.

Diesel pump Supplier:

Rsolid is a professional diesel fuel pump manufacturer provides high quality and durable diesel fuel pump replaements for different brands of engines or produce fuel pump according to your request. If you are looking for diesel pump or OEM engine parts, feel free to contact us.