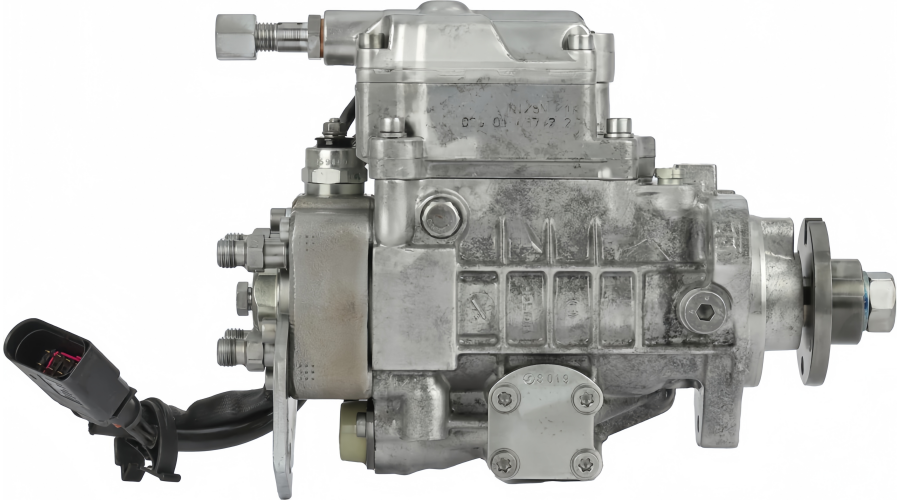

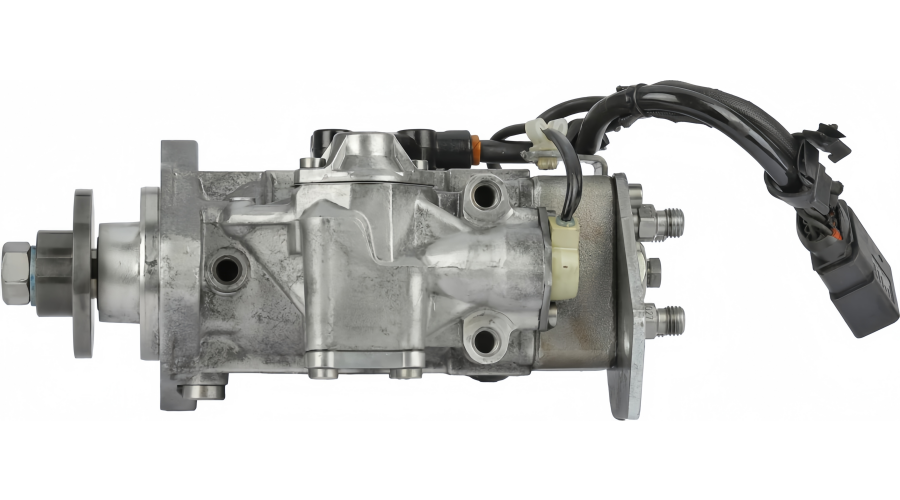

The Bosch VE pump was a landmark in diesel injection technology, bridging the gap between older inline pumps and modern common-rail systems. Here’s a detailed breakdown of its structural features and the resulting advantages.

1. Core Structural Features

a) Rotary Distributor Design (The "V" in VE)

Single High-Pressure Plunger: Unlike an inline pump with one plunger per cylinder, the VE pump uses one central plunger driven by a cam disc (cam plate). This plunger performs two functions:

Axial Movement: Reciprocates to create high pressure.

Rotary Movement: Spins to distribute the high-pressure fuel to each cylinder in firing order through a single outlet port aligned with a rotating distributor sleeve.

Result: A remarkably compact and lightweight unit compared to an inline pump.

b) Integrated Components

The VE is a highly integrated unit, often containing:

Vane-Type Transfer Pump: Built into the pump housing, it draws fuel from the tank and supplies low-pressure fuel to the high-pressure section. Its output pressure is often used for timing advance.

Mechanical Governor: Typically a centrifugal all-speed or variable-speed governor, integrated into the pump shaft. It controls the metering sleeve to maintain desired RPM regardless of load.

Timing Advance Mechanism: A hydraulic piston that uses fuel pressure from the vane pump to rotate the cam disc, advancing injection timing as engine RPM increases. This is crucial for efficiency and emissions.

Metering System: A control sleeve (spill sleeve) moved by the accelerator and governor determines how much fuel the plunger can take in before compression, thus controlling fuel quantity.

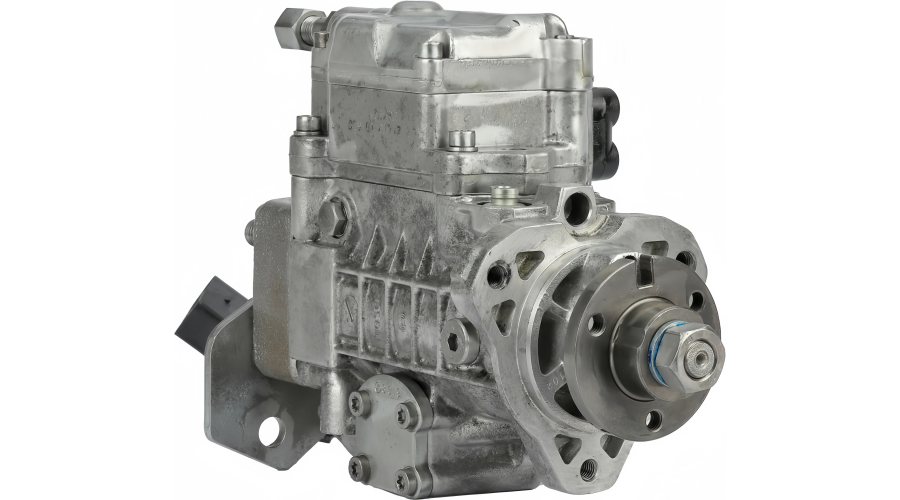

c) Specific Components (like for 0 460 414 987)

Boost Compensator (LDA - "Luftdruckabhangiger Anreicherer"): A hallmark of turbocharged applications. This is a diaphragm device connected to the intake manifold pressure. It "enriches" the fuel delivery as boost pressure rises, preventing smoke and improving power.

Cold Start Advance: A temperature-sensitive device that advances timing further when the engine is cold to improve startability and reduce white smoke.

Fuel Cut-Off Solenoid: An electrically activated valve on the inlet that shuts off fuel supply to stop the engine.

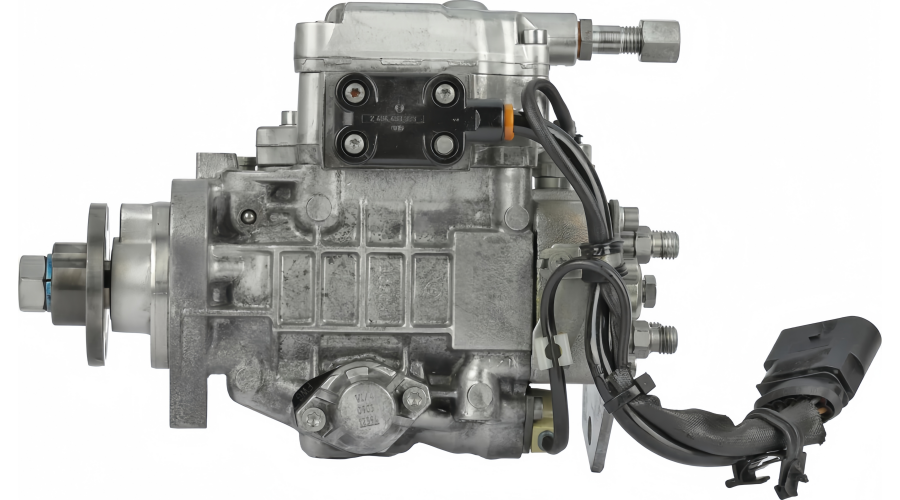

2. Key Advantages

These structural features led to significant benefits that made the VE pump dominant for two decades:

a) Compactness & Light Weight

Advantage: Its single-plunger, integrated design made it much smaller and lighter than an inline pump. This allowed easier installation on smaller, transverse-mounted engines in passenger cars (e.g., VW Golfs, Peugeot 205/305).

b) Cost-Effectiveness

c) Self-Lubrication & Sealed Design

Advantage: The pump is lubricated by the diesel fuel itself, eliminating the need for an engine oil supply connection. It's a closed, sealed unit, reducing contamination risk and simplifying plumbing.

d) Excellent Performance for Its Era

e) Reliability & Durability

f) Tunability

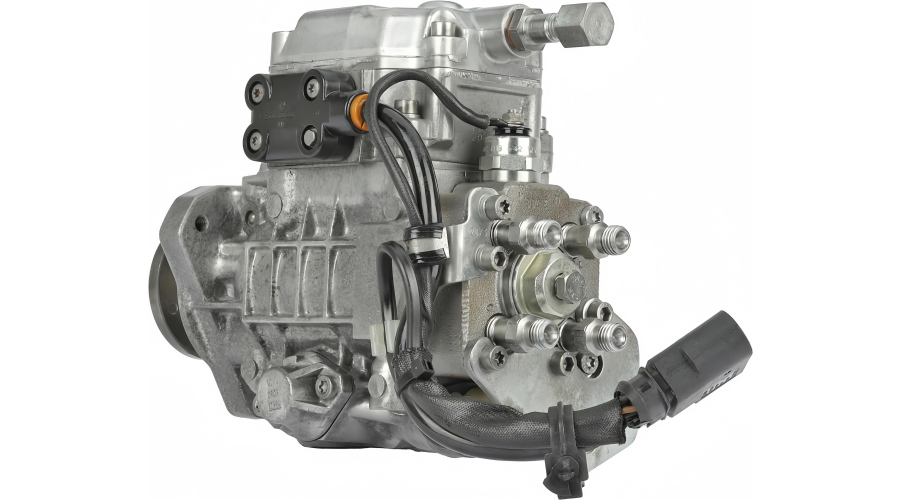

3. Structural Limitations / Trade-offs

Understanding its advantages also requires knowing its inherent limitations, which newer technologies eventually addressed:

Fixed Pressure Curve: Injection pressure is tied to engine RPM (via cam profile), unlike common-rail's independent, ultra-high pressure. This limits fuel atomization at low RPM.

Limited Injection Flexibility: It typically allows for only one main injection event per cycle. No pilot or post-injections for noise/emissions control.

Mechanical Control Lag: Response is mechanical/hydraulic, not instantaneous like electronic control.

Wear Sensitivity: The single plunger and distributor rotor are extremely high-precision parts. Wear here affects all cylinders, and repair requires specialized calibration.

Summary Table: Features vs. Advantages

| Structural Feature | Primary Advantage |

|---|

| Single Rotating Plunger | Compact size, low weight, lower cost. |

| Integrated Vane Pump & Governor | Self-contained unit, simplified installation. |

| Hydraulic Timing Advance | Improved efficiency and power across RPM range. |

| Boost Compensator (LDA) | Cleaner power from turbo engines, reduced smoke. |

| Fuel-Lubricated Design | Sealed system, reliable, no external oil lines. |

| Mechanical Control | Robust, repairable, tunable, independent of ECUs. |

In essence, the Bosch VE pump's genius was its integrated, rotary-distributor design. It packaged the essential functions of fuel injection—supply, high-pressure generation, metering, distribution, timing control, and governing—into one compact, reliable, and cost-effective unit. This perfectly met the needs of the booming passenger car diesel market from the late 1970s through the 1990s, before strict emissions laws mandated full electronic control.

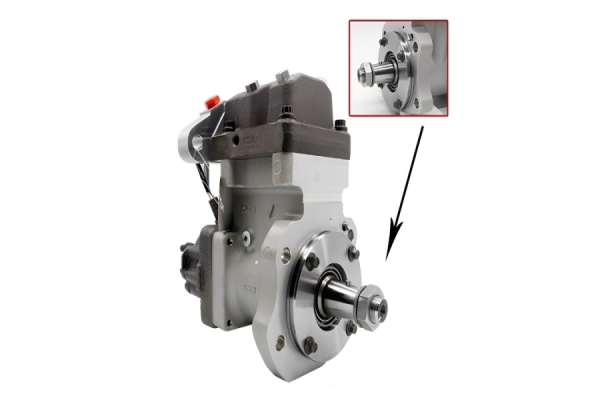

Where to buy Bosch VE pump ?

Rsolid is a professional manufacturer of fuel system components, providing high-quality and durable diesel fuel injectors and pump replacement parts for different brands of engines. The company is positioned as a professional and excellent supplier of automotive parts for foreign trade. With years of international market experience, Rsolid has become a reliable partner for global customers seeking engine parts and comprehensive value-added services from Denso, Bosch, Detroit, Cummins. The company is firmly committed to quality assurance, typically supported by international certifications commonly found in the automotive parts industry, ensuring that all parts undergo rigorous flow, pressure resistance, and leak integrity testing before being sold. Rsolid's business model typically involves maintaining diversity and comprehensive inventory of OEM and high-end aftermarket parts