Structural Characteristics

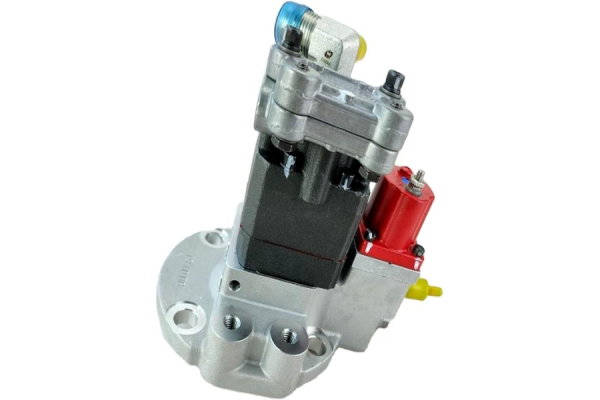

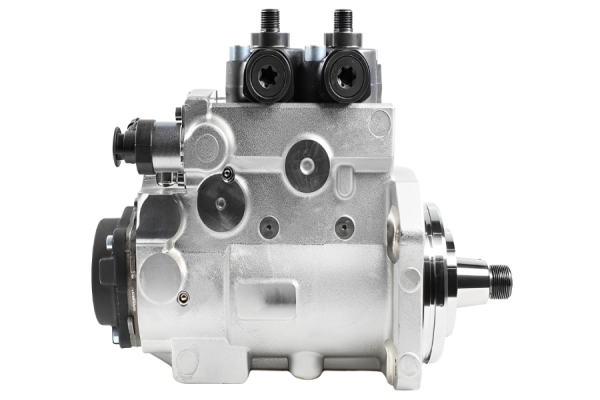

Robust Gear Design:

Structure: It features two tightly meshing, precision-machined steel gears (a drive gear and an idler gear) housed within a rigid pump body or housing. This is a classic external gear pump design.

Material: The gears are typically made from hardened, wear-resistant alloy steel.

Sealing: The gear teeth mesh with very tight clearances against the pump housing and side plates (also called wear plates), creating the sealing chambers necessary for pumping.

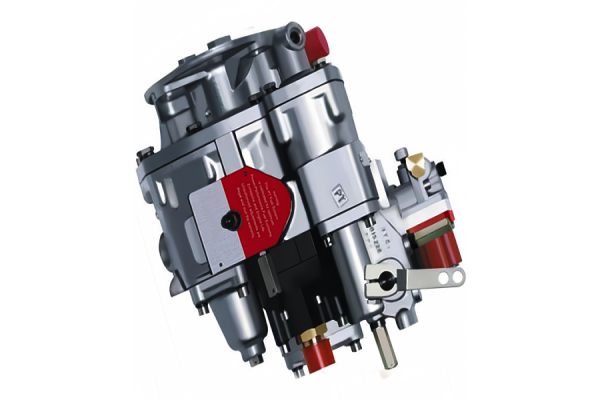

Integrated or Modular Design:

This pump is designed as a compact, self-contained unit that bolts directly to the engine block or gear housing, often driven by the engine's gear train. Its inlet and outlet ports are strategically positioned for direct connection to the fuel lines.

Built-in Pressure Regulation (on most models):

The pump incorporates a spring-loaded pressure relief valve. This is typically a simple piston or ball valve that bypasses excess fuel back to the inlet side when a preset pressure is exceeded.

Durable Drive Mechanism:

It features a splined or keyed heavy-duty drive shaft designed to handle the high torque from the engine without shearing. The shaft seal is robust to prevent external oil or fuel leaks.

Optimized Fluid Paths:

The internal passages (galleries) are designed to minimize flow restriction and avoid air traps, ensuring smooth fuel entry into the gear chambers and discharge to the outlet.

Technical Advantages

Deriving directly from the structure above, here are the key benefits:

High Reliability and Long Service Life:

Advantage: The simple, robust gear-and-housing design has very few moving parts. Hardened steel construction resists wear from fuel contamination far better than some vane-type designs. This makes it exceptionally durable for the 1,000,000+ mile life expected of an ISX/QSX engine.

Consistent, Pulse-Free Flow:

Advantage: As the gears rotate, they create a steady, continuous transfer of fuel in the spaces between the gear teeth and the housing. This provides a smoother, less pulsating flow to the high-pressure pump compared to some piston-type lift pumps, contributing to more stable injection system performance and reduced noise.

Excellent Priming and Self-Lubricating Ability:

Advantage: The tight meshing of the gears provides good suction (prime), helping to pull fuel from the tank. Furthermore, the fuel itself lubricates the gears and bearings, eliminating the need for a separate lubrication system and enhancing reliability.

Effective Performance Across a Wide RPM Range:

Advantage: Its output is directly proportional to engine speed (RPM). This means it delivers higher flow at high engine speeds (when demand is high) and sufficient flow at idle. The relief valve prevents over-pressurization at high RPM.

Tolerance to Marginal Viscosity and Contaminants:

Advantage: While clean fuel is always critical, the gear pump's robust design is generally more forgiving of temporary fuel viscosity changes (e.g., in very cold weather) and minor particulate contamination than more complex, tightly-toleranced pump types. It will wear rather than catastrophically fail in many scenarios.

Maintains System Pressure Under Load:

Advantage: The positive displacement design (a fixed amount of fuel is moved per revolution) ensures it can generate and maintain the required low-side fuel pressure (typically 30-70 psi) even against the resistance of filters and long fuel lines, which is crucial for preventing cavitation in the high-pressure injection pump.

Why This Matters for the ISX15/QSX15

These engines are workhorses in mining, trucking, and industrial applications. The 4062360 pump's design prioritizes:

Durability over lightweight complexity.

Consistent performance in dirty, high-vibration environments.

Simple serviceability—the entire unit is easily replaced as a module.

In summary, its structural simplicity is its greatest technical advantage, translating into the ruggedness, predictable flow, and long life that are non-negotiable for critical heavy-duty engine applications.