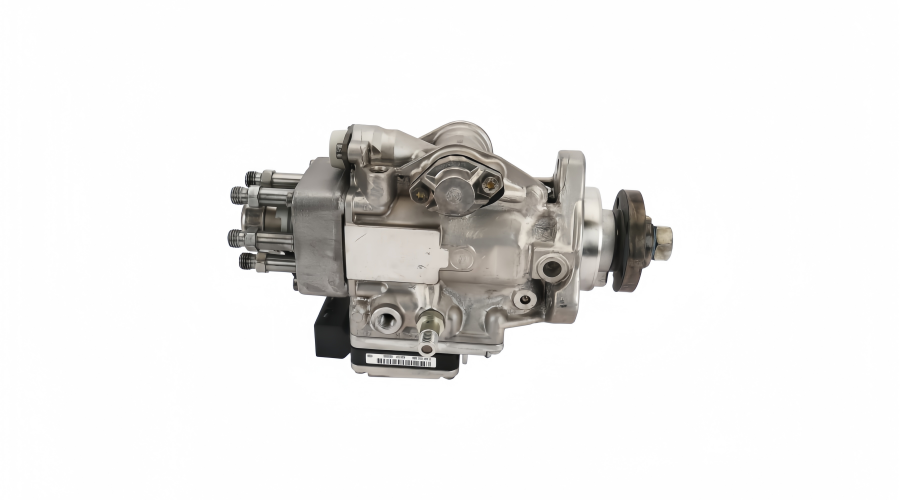

The Bosch VE (Verteiler Einspritzpumpe) pump, exemplified by the 0 470 006 001, was a revolutionary design that dominated small to medium-duty diesel engines for decades. Its structural advantages are the reason for its widespread use in tractors like New Holland, as well as in Volkswagen, Mercedes, and many others.

Here are the key structural advantages of the Bosch VE rotary distributor pump:

1. Compactness and Light Weight (High Power Density)

Structure: A single, compact housing contains all critical functions: the transfer pump, the high-pressure pumping element, the distributor head, the mechanical governor, and the advance mechanism.

Advantage: This integrated design is much smaller and lighter than an equivalent inline pump (which has a separate plunger and barrel for each cylinder). It simplified engine design, reduced installation space, and was ideal for transverse engine applications in vehicles and compact machinery.

2. Simplicity and Reduced Parts Count

Structure: Uses one central pumping plunger (driven by a cam plate) that performs two functions:

Axial Movement: Creates the high pressure.

Rotary Movement: Distributes this high-pressure fuel to each injector in the correct firing order via a single outlet port that aligns with individual cylinder ports in the distributor head.

Advantage: Fewer high-precision parts than an inline pump. This meant lower manufacturing costs, reduced potential failure points from wear between multiple plungers, and inherently balanced fuel delivery to all cylinders from a single source, minimizing calibration differences.

3. Integrated Mechanical Governor

Structure: The governor is housed within the main pump body. Centrifugal flyweights, driven by the pump shaft, act directly on the pumping plunger's stroke via a linkage and control sleeve.

Advantage: Provides precise, reliable, and immediate RPM control without external components. It's highly responsive to load changes (crucial for agricultural equipment), durable, and requires no external electrical power. The design allows for easy adjustment of idle and maximum RPM.

4. Integrated Hydraulic Advance Mechanism

Structure: Built into the pump's end. It uses fuel pressure (which rises with engine RPM) acting on a piston to rotate the internal cam plate, thereby advancing the injection timing as engine speed increases.

Advantage: Improves combustion efficiency, power, and fuel economy across the RPM range. It's a simple, self-contained, and reliable system that requires no external ECU or sensors.

5. The LDA (Load-Dependent Aneroid / Boost Compensator) - A Key Feature for Turbocharged Engines (like your New Holland)

Structure: A bolt-on module on top of the pump with a diaphragm. One side is connected to the engine's intake manifold (boost pressure), the other side acts on the fuel control lever through a spring.

Advantage: This is a brilliantly simple mechanical analog computer. As turbo boost increases, the diaphragm compresses the spring, allowing the control sleeve to move and increase the fuel delivery proportionally. This prevents smoke at low boost and safely maximizes power under load, a critical advantage for turbocharged agricultural diesels.

6. Sealed, Self-Lubricating, and Self-Cooling Unit

Structure: The pump is filled with diesel fuel, which lubricates all internal moving parts (cam plate, roller shoes, governor) and acts as a coolant.

Advantage: Eliminates the need for a separate oil supply. The continuous internal fuel circulation helps dissipate heat. This simplifies the overall engine system and enhances reliability.

7. Versatile and Modular Design

Structure: The basic VE pump platform could be easily adapted. Modules like the LDA (for turbo), EDC (Electronic Diesel Control solenoid), or a cold start advance could be added.

Advantage: Allowed Bosch to use the same core pump architecture across a vast range of engines—from passenger cars to tractors to industrial generators—by simply configuring these bolt-on options. Your 0 470 006 001 is a perfect example, using the mechanical governor + LDA combination ideal for a turbocharged tractor.

Primary Application on New Holland Engines

This pump model was commonly fitted to the New Holland (formerly Fiat) 3-cylinder and 4-cylinder diesel engines from the 1980s and 1990s. You will find it on:

Tractors: Models like the New Holland/Fiat 60-90 series (e.g., Fiat 580, 680, 780; New Holland 6640, 7740, etc.).

Combine Harvesters: Various New Holland combines using these engine families.

Skid Steer Loaders: Some models also utilized this engine and pump setup.

Specific Engines:

Fiat 8035 series (3-cylinder)

Fiat 8045 series (4-cylinder)

These engines were branded as "Fiat," "Fiatagri," or "New Holland" depending on the year and region.