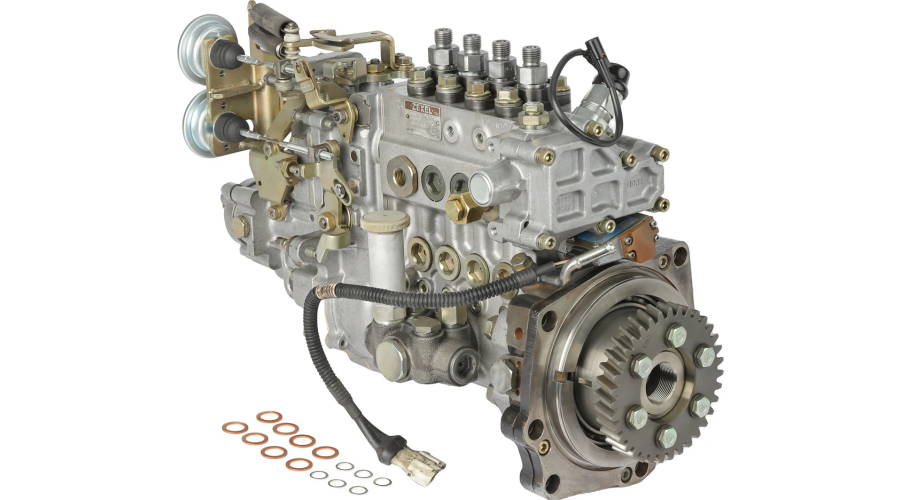

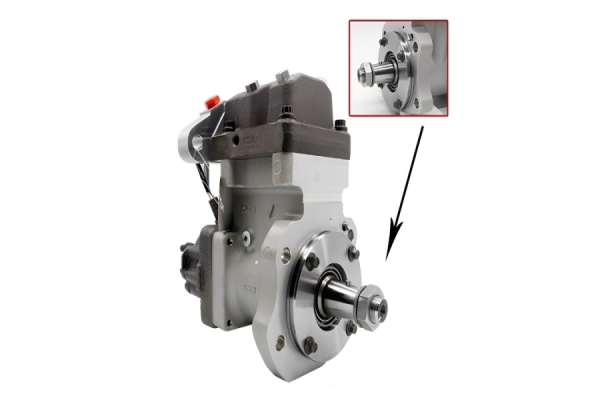

Part Number: 107492-1083

This is the core injection pump model number assigned by Zexel (now part of Bosch). This number identifies the specific design, internals, and calibration of the pump itself.

107492: Likely the base model or series identifier.

1083: The specific variant or calibration code. This suffix is critical as it defines the fuel delivery map, timing curve, and settings for a specific engine application.

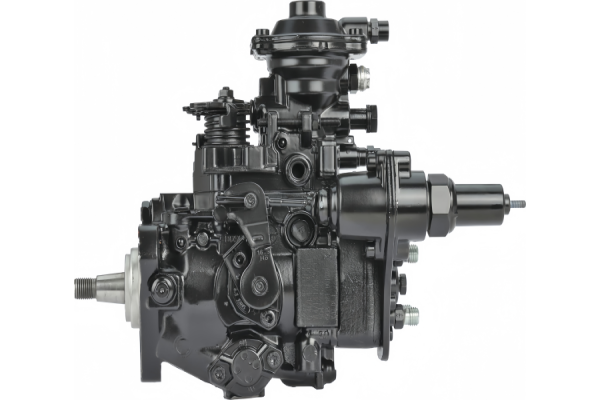

The Zexel (Diesel Kiki) 107492-1083 in-line plunger injection pump, and pumps of its type, represent a mature, robust design with distinct structural advantages that explain its legendary durability and continued use in industrial and heavy-duty applications.

Here are the key structural advantages:

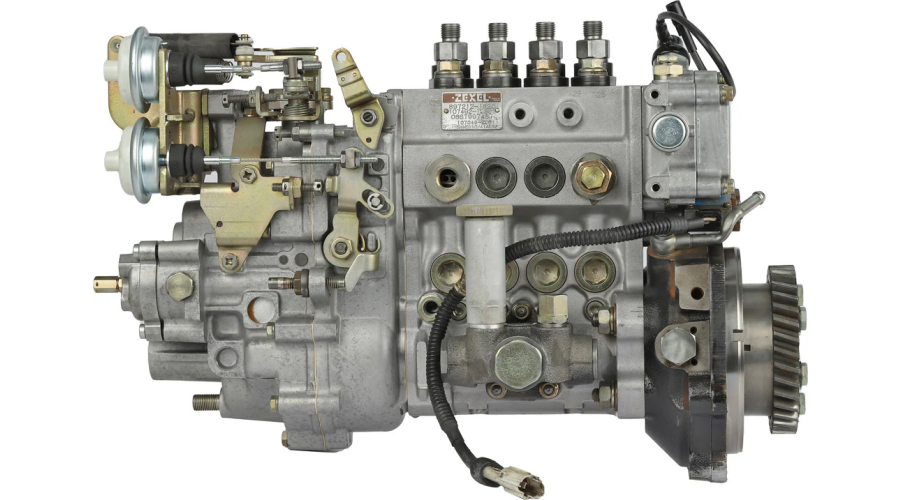

1. Modular & Serviceable Construction

Individual Plunger & Barrel Assemblies: Each cylinder has its own separate high-pressure pump element (plunger and barrel). These can be individually replaced, serviced, or swapped if only one is damaged, without requiring a full pump overhaul. This is a major advantage over rotary/distributor pumps where a single central element serves all cylinders.

Separate Delivery Valves: Each plunger assembly has its own delivery valve, which sharply cuts off fuel to prevent dribble and secondary injection. These are also individually replaceable.

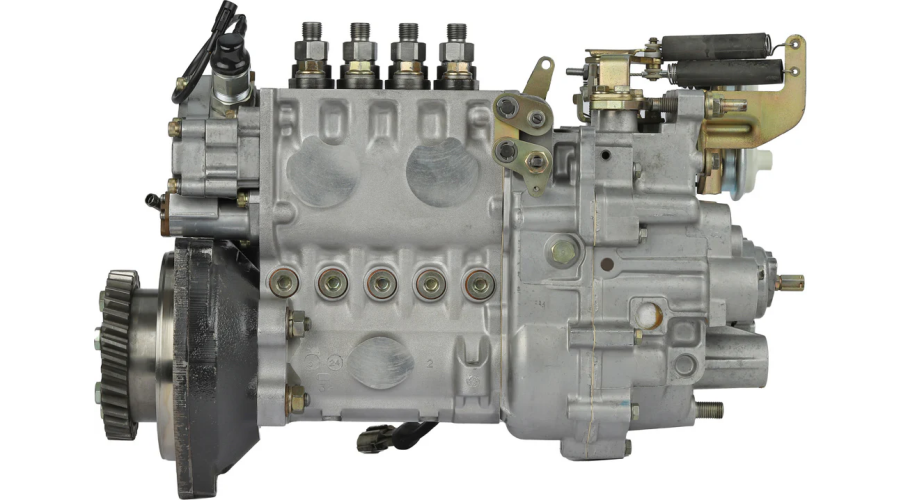

2. Inherent Strength and Rigidity

Heavy-Duty Housing: The main pump body is a substantial cast iron or aluminum alloy housing. This provides immense rigidity, resisting flex and torsional vibrations from the engine, which is critical for maintaining precise timing and alignment of internal components.

Robust Camshaft Drive: The pump is driven directly by the engine's gear train via a stout camshaft inside the pump. This direct-drive system handles high torque loads without slippage, ensuring accurate timing.

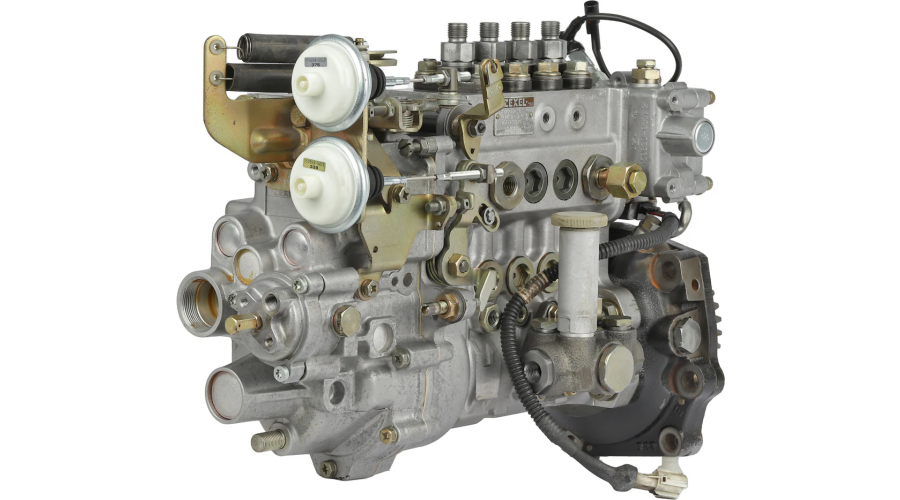

3. Excellent Contaminant Tolerance & Lubrication

Engine Oil Lubricated: Unlike many rotary pumps that rely solely on diesel for lubrication, this in-line pump is lubricated by the engine's oil system. This means:

Superior lubrication under all conditions.

Engine oil filters help keep the pump internals clean.

Much greater tolerance for minor fuel contaminants (like water) since the critical moving parts are not lubricated by the fuel itself.

Large Oil Sump: The pump housing acts as a sump, holding a significant volume of engine oil to ensure constant lubrication.

4. Precise and Independent Fuel Metering

Helix-Controlled Plungers: The fuel quantity for each cylinder is controlled by the rotational position of each plunger, which has a precision-machined helical groove. This is adjusted via a common rack-and-pinion gear system linked to all plungers. The design allows for extremely precise and synchronized fuel metering across all cylinders.

Individual Calibration: Each plunger/barrel set can be "phased" (timing of start of injection) and its rack position individually calibrated during assembly on a test bench, ensuring perfect balance between cylinders. This is a key reason for the smooth operation and efficiency of these engines.

5. Integrated Mechanical Governor

6. Built-In Mechanical Timing Advance

The pump contains an internal hydraulic/piston-type automatic timing advance mechanism. As engine speed increases, pressure from the transfer pump moves a piston, which rotates the internal camshaft relative to the drive shaft, advancing the injection timing.

Structural Advantage: This is a simple, robust, and reliable system housed entirely within the pump, requiring no external sensors or electronic controls. It optimizes performance and emissions across the RPM range purely through mechanical means.

7. High Pressure Capability and Longevity

The design is capable of generating the very high injection pressures (over 600 bar/8700 psi) required for good atomization in indirect injection (IDI) engines like the 4JB1.

The combination of engine oil lubrication, massive construction, and high-quality materials (hardened steel plungers, etc.) leads to an exceptionally long service life—often spanning the life of the engine itself with proper fuel filtration.

Comparison to Modern Systems: The Trade-Off

While structurally superior in terms of durability, repairability, and independence, these advantages come with trade-offs versus modern systems (like electronic unit pumps or common rail):

Disadvantage: Lower Precision & Flexibility: The mechanical calibration is fixed. It cannot adapt in real-time to altitude, temperature, or engine wear like an electronic system can.

Disadvantage: Lower Peak Pressure: It cannot achieve the ultra-high pressures (>2000 bar) of common rail systems needed for direct injection and modern emissions standards.

Disadvantage: Size and Weight: It is significantly larger, heavier, and more complex to install than a modern high-pressure pump.

Conclusion: The structural advantages of the Zexel 107492-1083 pump are robustness, serviceability, mechanical simplicity, and legendary durability. It is a masterpiece of mechanical engineering designed for a world where reliability, ease of repair in the field, and independence from complex electronics were paramount. This is precisely why it remains in use and is so valued in industrial, marine, and heavy-duty truck applications where these traits are more critical than achieving the absolute latest emissions standards.