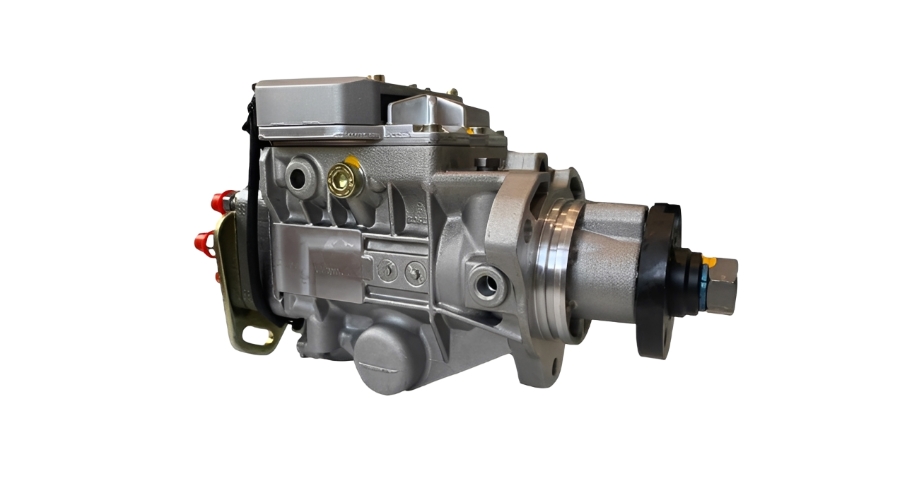

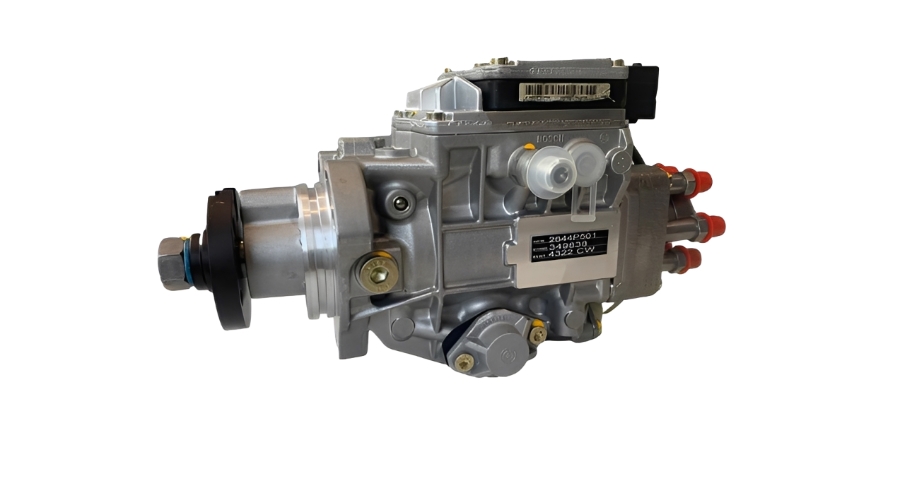

The Bosch VP30 Diesel Fuel Injection Pump (0470006003) is a high-performance rotary distributor pump designed for precision fuel delivery in diesel engines, particularly Perkins applications. Below is a detailed breakdown of its structural features, advantages, application scenarios, and compatible equipment.

1. Structural Features of the Bosch VP30 Pump

The VP30 is an electronically controlled rotary distributor pump with the following key components:

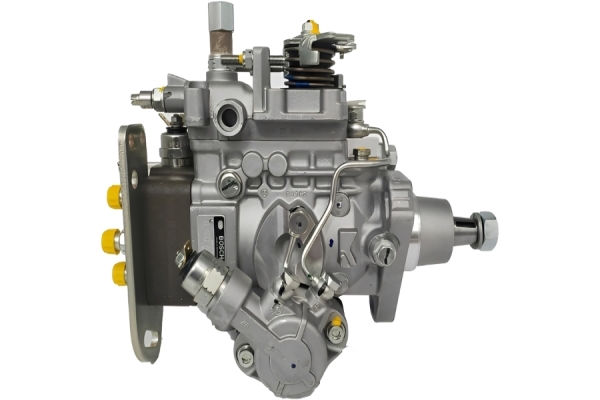

a. High-Pressure Fuel System

Radial-piston distributor design – Ensures even fuel distribution to each cylinder.

Electronically controlled metering valve – Adjusts fuel delivery based on ECU signals for optimal combustion.

Integrated pressure regulator – Maintains consistent high-pressure fuel supply (up to 1200 bar in some variants).

b. Electronic Control & Sensors

ECU-controlled solenoid valve – Precisely regulates injection timing and quantity.

Speed/timing sensors – Monitor crankshaft/camshaft position for synchronization.

Temperature and pressure feedback – Ensures adaptive performance under varying conditions.

c. Robust Construction

Aluminum alloy housing – Lightweight yet durable.

Hardened steel internal components – Resists wear from high-pressure diesel.

Sealed bearings & shafts – Minimizes fuel leakage and contamination.

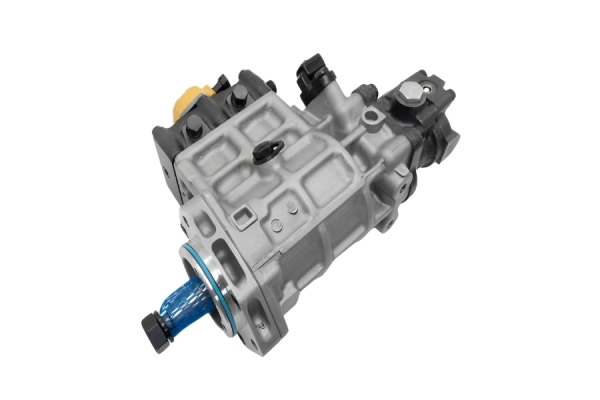

d. Compact & Modular Design

Single-unit construction – Combines fuel supply, high-pressure generation, and distribution in one compact unit.

Easy integration – Fits Perkins engines without extensive modifications.

2. Key Advantages of the VP30 Pump

| Feature | Benefit |

|---|

| Electronic Control | Enables precise fuel metering, improving efficiency and reducing emissions. |

| High Injection Pressure (up to 1200 bar) | Enhances fuel atomization for better combustion and power output. |

| Self-Lubricating Design | Reduces wear and extends service life. |

| Adaptive Timing Control | Optimizes performance across different RPM ranges. |

| Low Maintenance Requirements | Fewer moving parts compared to inline pumps, reducing failure risks. |

| Compatibility with Biofuels | Can handle biodiesel blends (with proper maintenance). |

3. Application Scenarios & Compatible Equipment

The VP30 pump is widely used in industrial, agricultural, construction, and marine applications due to its reliability and efficiency.

a. Common Perkins Engines Using VP30 Pumps

Perkins 1100 Series (e.g., 1104C-44, 1104D-44)

Perkins 1103 Series (some variants)

Perkins 1106 Series (in certain configurations)

b. Equipment & Machinery Applications

| Industry | Typical Applications |

|---|

| Agriculture | Tractors, combine harvesters, irrigation pumps. |

| Construction | Excavators, loaders, bulldozers, generators. |

| Marine | Auxiliary engines, small boats, fishing vessels. |

| Power Generation | Backup generators, industrial diesel gensets. |

4. Comparison with Other Injection Pumps

| Feature | VP30 Pump | Traditional Inline Pump | Common Rail System |

|---|

| Control Type | Electronic | Mechanical | Fully Electronic |

| Max Pressure | ~1200 bar | ~800 bar | 2000+ bar |

| Precision | High | Moderate | Very High |

| Cost | Moderate | Low | High |

| Maintenance | Moderate | High | Low (but complex) |

Why Choose VP30?

It strikes a balance between performance, cost, and reliability, making it ideal for medium-duty diesel engines where full common rail systems are unnecessary.

5. Maintenance & Troubleshooting Tips

Use clean, high-quality diesel (contaminants can damage precision components).

Regularly inspect electrical connectors (corrosion can disrupt ECU signals).

Check for fuel leaks (common around seals after prolonged use).

Monitor injection timing (wear can cause delayed fuel delivery).

Conclusion:

The Bosch VP30 (0470006003) is a robust, electronically controlled diesel injection pump optimized for Perkins engines in demanding environments. Its high-pressure capability, precise electronic control, and durability make it a preferred choice for agricultural, construction, marine, and power generation applications.