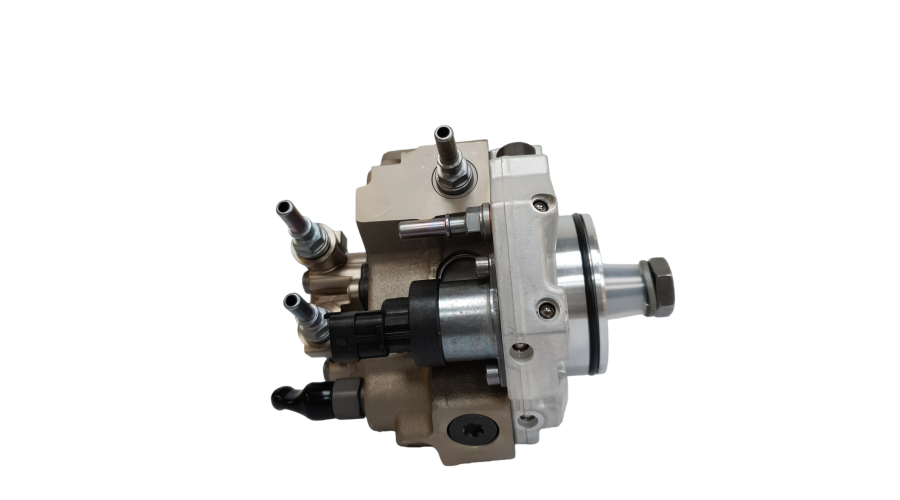

Core Part Information

Part Number: 0445020122

Description: High-Pressure Fuel Pump (Fuel Supply Pump)

Engine Application: Specifically designed for Cummins QSB Series diesel engines, most commonly the:

System: This is a critical component of the High-Pressure Common Rail (HPCR) fuel system.

Typical Equipment Applications

This pump is found in a wide range of machinery and vehicles powered by Cummins QSB engines, including:

Construction Equipment: Excavators, wheel loaders, bulldozers, forklifts.

Power Generation: Diesel generator sets.

Agricultural Machinery: Large tractors, combines.

Industrial & Marine: Some marine propulsion and industrial power units.

Commercial Vehicles: Certain medium-duty trucks and buses.

Function & Importance

Primary Role: As the heart of the HPCR system, this pump takes low-pressure fuel from the tank and pressurizes it to extremely high levels (typically 1600 - 2000+ bar or 23,000 - 29,000+ PSI). It then supplies this high-pressure fuel to the common rail (accumulator).

Critical Impact: It is essential for maintaining precise fuel pressure to the electronic injectors, directly affecting:

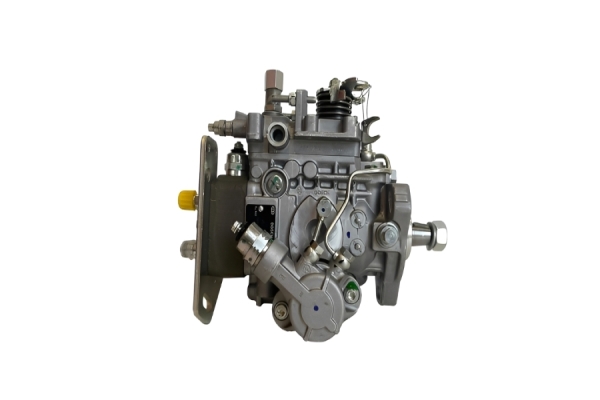

Structural Characteristics and Technical Advantages of the High-Pressure Fuel Pump (0445020122)

Structural Characteristics:

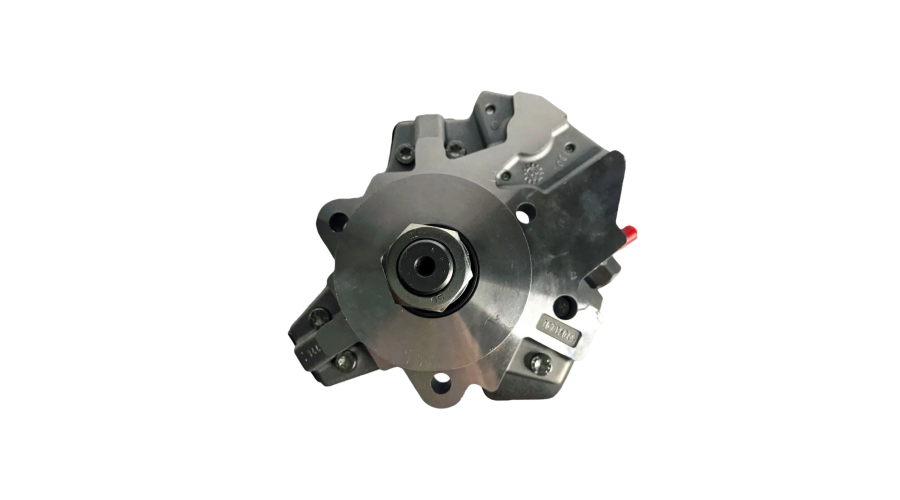

A. Compact Modular Design:

Integrated Design: Combines low-pressure transfer pump, high-pressure pumping elements, pressure regulation valve, and fuel metering unit into a single compact housing

Radial Piston Arrangement: Typically features 3 or 4 radially arranged plunger/piston assemblies driven by an eccentric cam

Gear-Driven Operation: Directly driven by the engine gear train at camshaft speed (1:2 crankshaft ratio)

B. Key Components:

Inlet Metering Valve (IMV): Electronically controlled proportional valve regulating fuel entering the high-pressure section

Pressure Relief Valve: Spring-loaded safety mechanism preventing excessive pressure buildup

Plunger and Barrel Assemblies: Precision-machined hardened steel components with micron-level clearances

Tappet and Roller Assemblies: Convert cam motion to plunger movement with minimal friction

Integrated Fuel Temperature Sensor: Monitors fuel temperature for density compensation

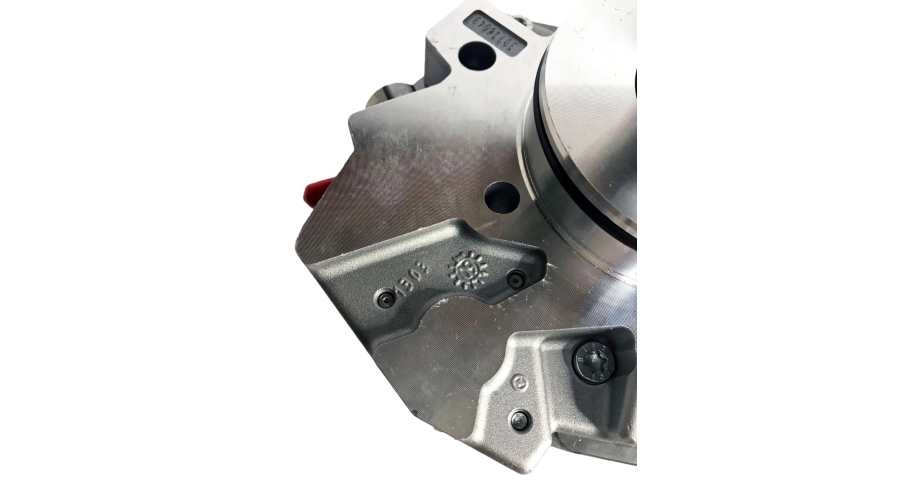

C. Material Construction:

High-Grade Alloy Steel: For plungers, barrels, and cam surfaces

Advanced Surface Treatments: Diamond-like carbon (DLC) coatings, nitriding, or chromium plating for wear resistance

Precision Bearings: High-load capacity bearings supporting the camshaft

Technical Advantages:

A. Performance Excellence:

Exceptional Pressure Generation: Capable of producing 1,600-2,000+ bar (23,000-29,000+ psi) rail pressure

High Volumetric Efficiency: Typically 85-92% across operating range

Precise Flow Control: IMV provides accurate metering with response times < 10ms

Wide Operating Range: Functions efficiently from idle (600 rpm) to maximum engine speed (2,800+ rpm)

B. Durability & Reliability:

Extended Service Life: Designed for 8,000-12,000+ hours in heavy-duty applications

Contamination Tolerance: Robust filtration requirements (typically 4-10 micron) but designed to withstand some contamination

Thermal Stability: Maintains performance across -40°C to +140°C fuel temperatures

C. System Integration Advantages:

Simplified Plumbing: Reduces external high-pressure lines compared to earlier systems

Built-In Diagnostics: Supports comprehensive fault detection through the ECM

Adaptive Control: Self-learning capability for wear compensation over service life

Reduced NVH: Optimized cam profiles and balanced design minimize noise and vibration

D. Emission Compliance:

Enables ultra-fine fuel atomization (droplets < 5 microns)

Supports multiple injection events per cycle (pilot, main, post)

Facilitates precise injection timing critical for meeting Tier 3/4, EPA 2010+ standards