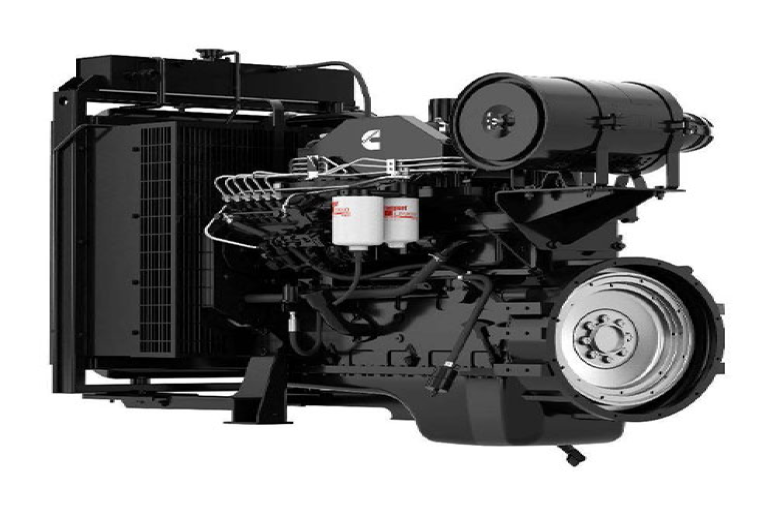

How much do you know about the internal structure and daily maintenance of Cummins' 6BT5.9 engine ?

The Cummins 6BT5.9 engine is a widely used diesel engine known for its reliability and durability. Below is a detailed breakdown of its diesel system components, functions, applications, common problems, and maintenance suggestions.

1. Main Components & Functions of the Diesel System

The diesel system in the 6BT5.9 consists of several key components:

Fuel Supply System

Fuel Tank – Stores diesel fuel.

Fuel Transfer Pump (Lift Pump) – Draws fuel from the tank and supplies it to the injection pump.

Fuel Filters (Primary & Secondary) – Remove contaminants to protect the injection system.

Primary filter (water separator) removes water and large particles.

Secondary filter (fine filtration) ensures clean fuel reaches the injectors.

Injection Pump (Rotary or Inline) – Pressurizes and delivers fuel to the injectors at precise timings.

Common models: Bosch VE rotary pump or Bosch P7100 inline pump.

Fuel Injectors – Atomize fuel into the combustion chamber.

Fuel Return Line – Returns excess fuel to the tank.

Air Intake & Turbocharging (if equipped)

Turbocharger (optional, in some models) – Increases air intake for better combustion efficiency.

Intercooler (if turbocharged) – Cools compressed air for denser intake.

Governor & Control System

Mechanical or electronic governor regulates engine speed.

2. Main Application Scenarios & Equipment Models

The 6BT5.9 is used in a variety of industries due to its 135–230 HP power range and 5.9L displacement.

Common Applications:

Trucks & Commercial Vehicles

Dodge Ram (1st Gen Cummins, 1989–1993)

Freightliner, International trucks

Construction & Agricultural Equipment

Bobcat skid steers, Case backhoes

John Deere tractors

Marine Engines

Small boats, work vessels

Generators & Industrial Power Units

Used in standby and prime power gensets

Military & Emergency Vehicles

Humvees, fire trucks

3. Common Problems & Maintenance Suggestions

Despite its reliability, the 6BT5.9 has some recurring issues:

A. Fuel System Problems

Clogged Fuel Filters

Symptoms: Hard starting, power loss, rough idle.

Solution: Replace filters every 10,000–15,000 miles (or per OEM recommendation).

Air in Fuel System

Symptoms: Engine stalling, difficulty starting.

Solution: Bleed the system by loosening injector lines and cranking until fuel flows cleanly.

Injector Failure

Symptoms: Excessive smoke (black/white), misfires.

Solution: Test injectors, replace if leaking or clogged.

Injection Pump Wear (VE Rotary Pump Issues)

Symptoms: Loss of power, erratic RPM, hard cold starts.

Solution: Rebuild or replace the pump; avoid low-quality diesel.

B. Turbocharger Issues (If Equipped)

Oil Leaks / Turbo Failure

Symptoms: Blue smoke, whining noise, power loss.

Solution: Check oil supply, replace seals or turbo if damaged.

C. Cooling System Problems

Overheating

Causes: Clogged radiator, faulty thermostat, water pump failure.

Solution: Flush coolant system, replace worn components.

D. Oil Leaks (Common Areas)

Rear Main Seal, Valve Cover Gasket, Front Crankshaft Seal

Solution: Replace seals with high-quality parts.

E. KDP (Killer Dowel Pin) Issue (Early Models)

Problem: The front gear train dowel pin can work loose and damage the timing gear.

Solution: Inspect and secure the pin (aftermarket kits available).

4. Maintenance Recommendations

Regular Oil Changes – Every 5,000–7,500 miles (use 15W-40 diesel oil).

Fuel Filter Replacement – Every 10,000–15,000 miles.

Coolant Flush – Every 2–3 years (use extended-life coolant).

Injector & Pump Service – Inspect every 50,000 miles.

Turbo Maintenance – Check for shaft play, ensure proper oil supply.

Conclusion

The Cummins 6BT5.9 is a robust engine widely used in trucks, construction equipment, and generators. Fuel system maintenance, turbo care, and leak prevention are key to longevity. Addressing common issues like clogged filters, injector problems, and KDP risks will ensure reliable performance for years.