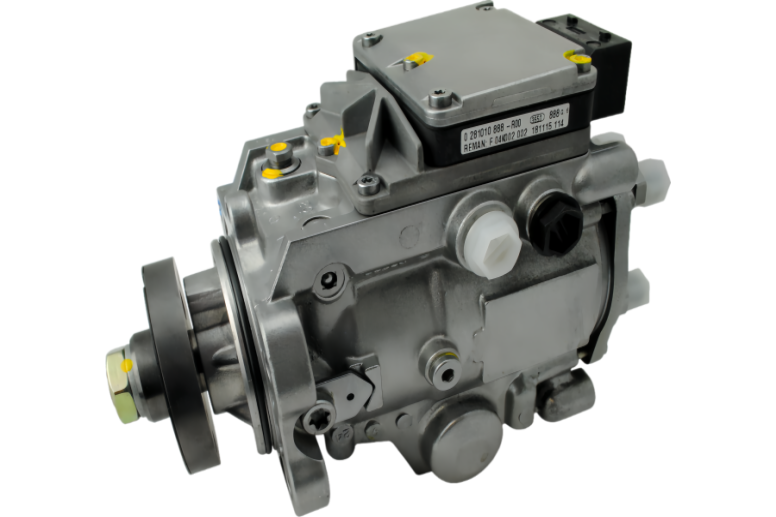

Structural characteristics and installation precautions of Bosch VP44 diesel pump

The Bosch VP44 is a landmark diesel injection pump that played a crucial role in transitioning from purely mechanical to electronic diesel control. Here’s a breakdown of its structural advantages and main application scenarios.

Structural Advantages of the Bosch VP44

The VP44 (Radial Piston Distributor Pump with electronic control) is often called an "electronic rotary pump." Its key structural advantages stem from its hybrid design:

1. High-Pressure Capability & Precision:

Radial Piston Design: Unlike axial-piston distributor pumps, the VP44 uses multiple radial pistons (typically four) arranged like a star around the central driveshaft. This allows for a very robust design capable of generating extremely high injection pressures for its era—up to 2050 bar (~30,000 psi) in its peak versions.

High Pressure = Better Atomization: These pressures enabled finer fuel atomization, leading to more complete combustion, increased power, improved fuel efficiency, and reduced emissions compared to its predecessors.

2. Integrated Electronic Control (The Defining Feature):

VP44 is Not a "Purely Mechanical" Pump: Its core advantage is the integrated electronic control unit (ECU), housed in a "computer box" on top of the pump. This made it one of the first widely used electronic diesel injection pumps.

Solenoid-Controlled Spill Valve: At its heart is a high-speed solenoid valve (spill valve). The ECU precisely controls the exact moment this valve closes (start of injection) and opens (end of injection). This allows for:

Precise Timing Control: Injection timing can be dynamically adjusted based on engine load, speed, and temperature for optimal performance.

Variable Injection Quantity: Exact fuel metering per cylinder.

Pilot Injection: Some VP44 variants could perform pilot injection (a small pre-injection before the main injection), significantly reducing combustion noise (diesel knock) and NOx emissions.

3. Compact Distributor Design:

As a single-plunger distributor pump, it uses one set of high-pressure pistons to supply fuel to all cylinders (typically 4 or 6) in firing order. This makes it more compact and lighter than an equivalent inline pump (like the Bosch P7100), simplifying engine integration.

4. Self-Lubrication & Drive:

The pump is lubricated by the diesel fuel itself ("lubricated by fuel") and is directly driven by the engine's timing gear/belt. This eliminates the need for a separate oil supply but also makes it critically dependent on clean, adequate fuel for lubrication.

Main Application Scenarios

The VP44 was primarily used in high-performance, light and medium-duty diesel applications during the late 1990s and early 2000s. It was the pump that brought electronic control and its benefits to many popular platforms.

1. Automotive - High-Performance Passenger & Light Commercial Vehicles:

This was its primary domain. It powered some of the most iconic turbo-diesel vehicles of its time:

European Market:

Alfa Romeo: 2.4 JTD (5-cylinder) engines.

Opel/Vauxhall/SAAB: 2.0 DTI and 2.2 DTI engines.

Rover: 2.0 L-Series diesel.

Ford: Endura-DI and later Duratorq DI engines.

Fiat: 1.9 JTD and 2.4 JTD.

Asian Market:

Isuzu: 4JG2 engine used in Trooper, Bighorn, and some commercial vehicles.

North American Market (as a notable application):

Dodge Ram Cummins 5.9L 24V (1998.5-2002): This is arguably the most famous application in the US. The "24-valve" Cummins with the VP44 was known for its strong performance and smooth operation compared to the prior mechanical P7100 pump, but it also highlighted the pump's vulnerability to low fuel lubrication (leading to widespread aftermarket lift pump upgrades).

2. Agricultural & Industrial Machinery:

Used in certain mid-range tractors and construction equipment that required the benefits of electronic control for emissions and power management.

Key Considerations & Legacy

Vulnerability: The VP44's main weakness was its dependence on fuel for lubrication and cooling. A failing in-tank lift pump, clogged filters, or running the tank low could cause catastrophic failure due to "fuel starvation." The integrated ECU was also susceptible to heat and vibration damage.

Transitional Technology: The VP44 was a bridge between purely mechanical systems and the next generation: Common Rail. By the mid-2000s, Common Rail technology (with even higher pressures, full flexibility in injection timing/quantity, and multiple injections per cycle) became dominant, making the VP44 obsolete for new designs.

Tuner/Enthusiast Favorite: Due to its electronic nature, the VP44 was relatively easy to "chip tune" by remapping the ECU, making it popular for performance upgrades, especially in the Cummins truck community.

In summary, the Bosch VP44's structural advantages were its high-pressure radial piston design and, most importantly, its integrated electronic control, enabling unprecedented precision in diesel injection for its time. Its main application was in performance-oriented passenger cars, vans, and light trucks in the late 90s and early 2000s, where it significantly improved power, refinement, and efficiency over previous mechanical pumps.

Proper installation of a Bosch VP44 pump is critical to its longevity and performance. Due to its high-pressure, fuel-lubricated, and electronically controlled design, even small oversights can lead to rapid and expensive failure. Here are the essential precautions, structured in order of importance.

Core Principle: The VP44 is Fuel-Lubricated & Cooled

Every precaution stems from this fact. The fuel is its lifeblood. Any air, contamination, or insufficient flow will destroy it.

Pre-Installation Precautions

1. Verify Component Health & Compatibility:

Lift Pump is NON-NEGOTIABLE: Ensure the vehicle's in-tank or inline lift pump is brand new or verified to be in perfect working order. It must supply a minimum of 14 PSI (1 bar) at the VP44 inlet under all engine load conditions, with a typical spec of 15-20 PSI (1-1.4 bar). Do not assume the old one is good.

Fuel Filter: Install a new, high-quality OEM-style fuel filter. Consider adding a quality water separator if the vehicle doesn't have one.

Fuel Lines & Tank: Inspect all lines for cracks and the tank for debris. Clean the tank if there's any suspicion of contamination.

New Pump or Rebuilt? Only use a pump from a highly reputable rebuilder or a known-good used unit. Ensure the pump model number matches the vehicle's exact application (engine ECU calibration is often pump-specific).

2. The "Golden Rule" - NEVER DRY-RUN THE PUMP:

The VP44 pump must NEVER be turned without fuel inside it for lubrication. This includes cranking the engine.

Pre-Filling Procedure: Before installing the pump, fill its internal fuel gallery through the inlet port using clean, filtered diesel fuel. Rotate the pump drive shaft by hand a few times to distribute fuel. The pump should be full of fuel before it's bolted on.

Installation Procedure Precautions

1. Timing is Critical (Mechanical & Electronic):

Engine Static Timing: This is the most crucial mechanical step. You MUST set the engine to its exact Top Dead Center (TDC) on cylinder #1 compression stroke (consult the engine manual).

Pump Drive Alignment: The pump's drive shaft has a specific alignment slot/key. It must mate perfectly with the engine's drive gear. The pump housing also has a timing mark that must align with the engine's timing mark. Misalignment by even one tooth will cause poor performance, hard starting, or engine damage.

Use the Correct Tools: A proper injection pump locking pin (to hold the internal rotor in the correct position) and timing case alignment tools are often required. Do not guess.

2. Connection Precautions:

Fuel Lines: Connect the fuel return line first to prevent pressure buildup during priming. Ensure all banjo bolts and washers are clean and used with new sealing washers.

Electrical Connector:

Ensure the connector and the pump's socket are clean, dry, and free of corrosion.

Apply a light smear of dielectric grease to the seals to prevent moisture ingress.

Connect it securely last, after the pump is physically mounted and fuel lines are attached.

Post-Installation & Priming Precautions (THE MOST CRITICAL PHASE)

1. Prime the Fuel System COMPLETELY:

Goal: Remove ALL air from the system, from the tank to the injection pump and high-pressure lines.

Method:

Disconnect the electrical connector to the fuel cutoff solenoid on the pump (if applicable) or disable the ECU to prevent the engine from starting.

Turn the ignition to "ON" to activate the lift pump. Let it run for at least 60-90 seconds. Listen for the lift pump humming.

Crack open (loosen) the fuel inlet line nut at the VP44 to bleed air. Tighten once a solid stream of fuel with no bubbles emerges.

Crack open the fuel return line nut at the VP44 and repeat.

For final bleeding, crack open the injection line nuts at the fuel injectors (one at a time) while cranking the engine briefly (for 10-15 seconds max). Tighten each as fuel sprays out.

Never crank the engine excessively during priming. Short bursts only.

2. First Start & Initial Run:

Reconnect all electrical connections.

Start the engine. It may take a few extra seconds of cranking.

Immediately after starting, check for fuel leaks at all connections.

Listen for abnormal noises from the pump (whining, grinding). A smooth hum is normal; loud knocking or screeching indicates immediate shutdown is required.

Long-Term Health Precautions

1. Fuel Quality is Paramount:

Always use clean, high-quality diesel fuel. The VP44's tolerances are extremely tight.

In regions with low lubricity diesel (like ULSD in North America), consider a reputable diesel fuel additive that boosts lubricity (e.g., additives containing oleic acid or other lubricity enhancers).

2. Maintenance Discipline:

Change the fuel filter at half the recommended interval, especially on older vehicles. This is cheap insurance.

Never, ever run the tank low. This increases the risk of pulling air and sediment into the system. Keep it above 1/4 tank as a habit.

Inspect the lift pump pressure regularly if you have a gauge installed.

3. Electrical & Heat Protection:

Ensure the pump's ECU cooling fan (mounted on the side of the pump's control unit) is functioning and its intake is not blocked by debris.

Check that the wiring harness is secure and not rubbing against anything that could cause a short.